A kind of burner optimization control method and device

A burner and control model technology, applied in the combustion method, the safety device of the combustion chamber, the combustion chamber, etc., can solve the problems of the ratio control cannot be effectively monitored, the difficulty is large, and the combustion efficiency is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

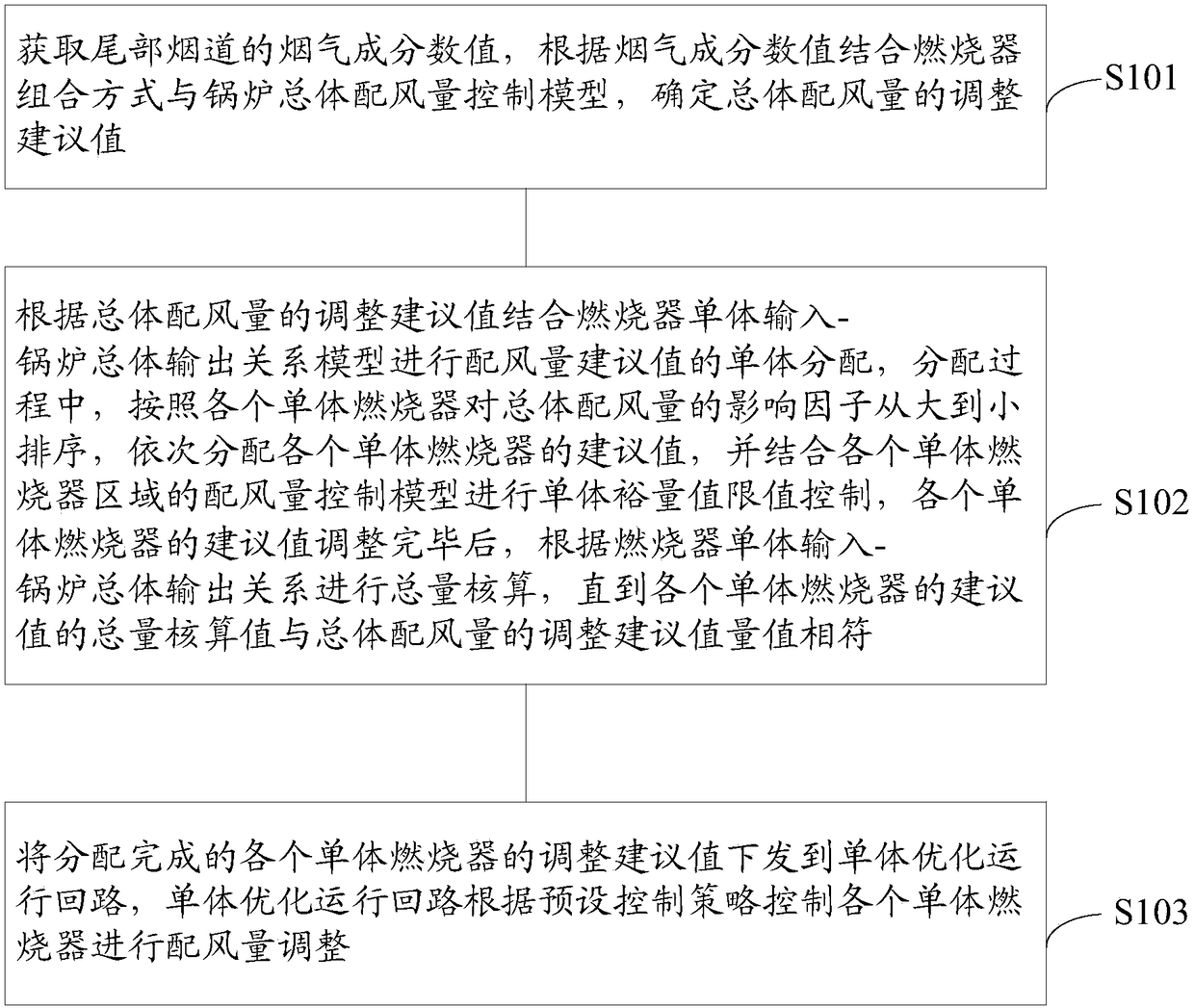

[0084] figure 1 It is a schematic flow chart of the burner optimization control method of the embodiment of the present application, such as figure 1 Shown:

[0085] In order to solve the above technical problems, the first aspect of the present application provides a burner optimization control method, including:

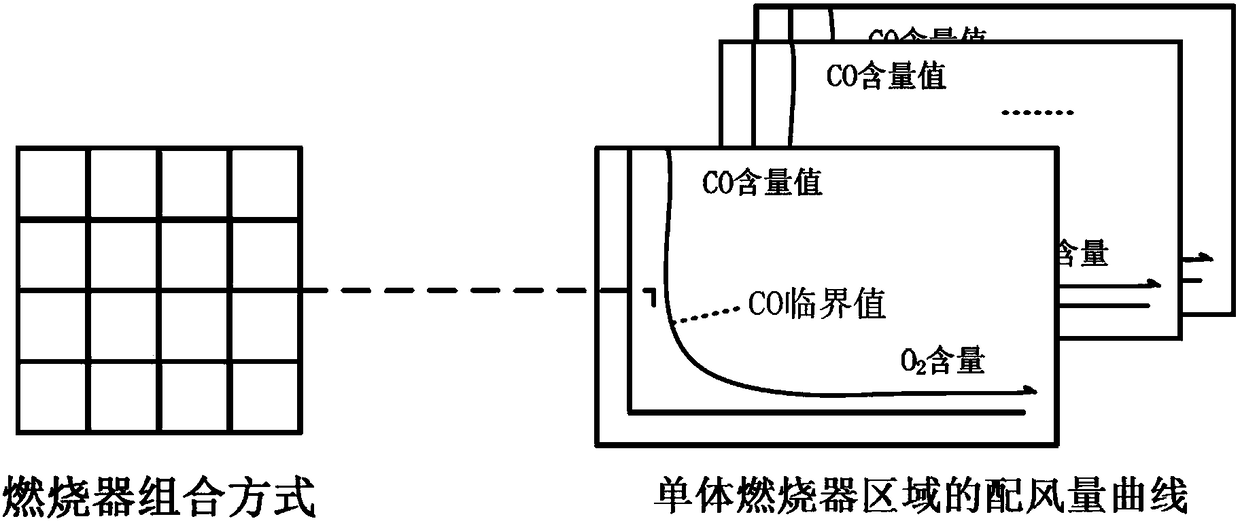

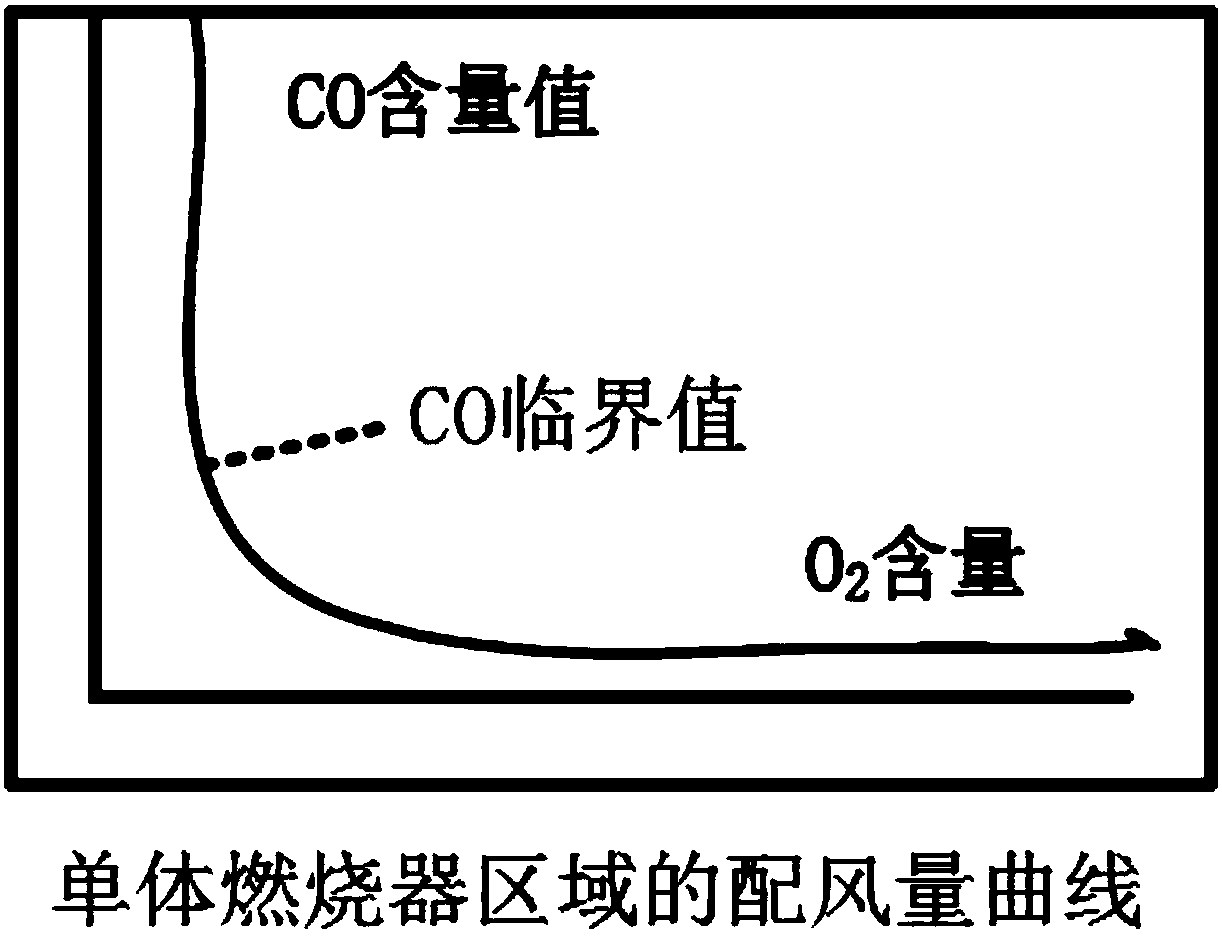

[0086] Step S101: Obtain the flue gas composition value of the tail flue, and determine the suggested adjustment value of the overall air distribution volume according to the flue gas composition value combined with the burner combination mode and the overall boiler air distribution volume control model;

[0087] Step S102: According to the recommended adjustment value of the overall air distribution volume combined with the burner unit input-boiler overall output relationship model, the individual distribution of the recommended air distribution volume is carried out. During the distribution process, according to the influence factors of each individual burner on...

Embodiment 2

[0137] Figure 6 is a schematic structural view of the burner optimization control device of the embodiment of the present application, Figure 7 It is a structural schematic diagram of another burner optimization control device according to the embodiment of the present application, such as Figure 6 and 7 Shown:

[0138] Correspondingly, the second aspect of the present application also provides a burner optimization control device, including:

[0139] Obtaining module 1, obtaining the flue gas component value of the tail flue, and determining the suggested adjustment value of the overall air distribution volume according to the flue gas component value combined with the burner combination mode and the overall boiler air distribution volume control model;

[0140] The allocation module 2 is used to distribute the suggested value of the air distribution volume according to the suggested adjustment value of the overall air distribution volume combined with the burner indivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com