Cooling liquid circulation system of high-load CPU mist spraying phase-change refrigerating device and control method of cooling liquid circulation system

A technology of a refrigeration device and a circulation system, which is applied to the cooling liquid circulation system of a high-load CPU spray phase-change refrigeration device and its control field, can solve the problems of easy scaling or blockage, large pressure loss, and high requirements, and achieves high heat dissipation efficiency, The effect of reducing installation space and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

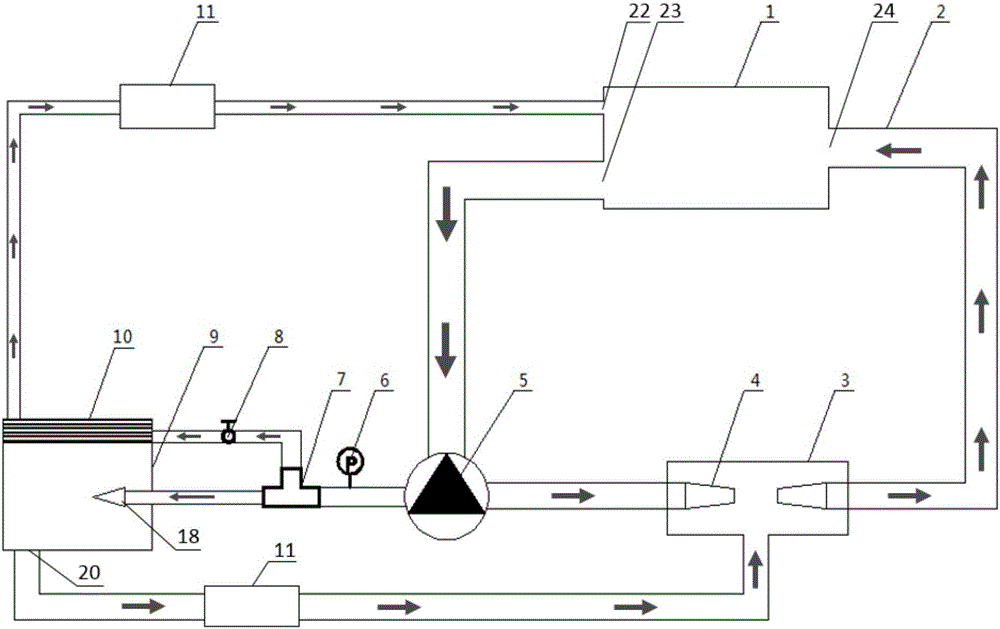

[0036] figure 1Shown is an embodiment of the coolant circulation system of the high-load CPU spray phase-change refrigeration device of the present invention, and the coolant circulation system of the high-load CPU spray phase-change refrigeration device includes a coolant tank 1, a pipeline 2, a jet Chamber 3, micropump group 5, tee 7, spray chamber 9, condenser 10, radiator 11 and single-chip microcomputer 26.

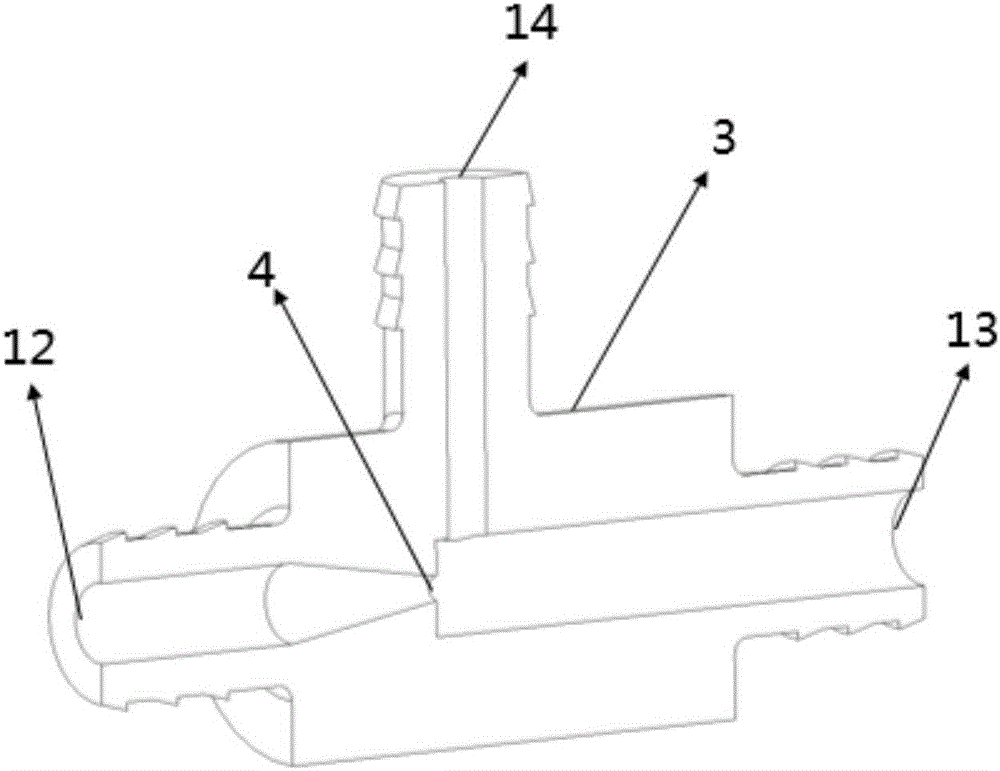

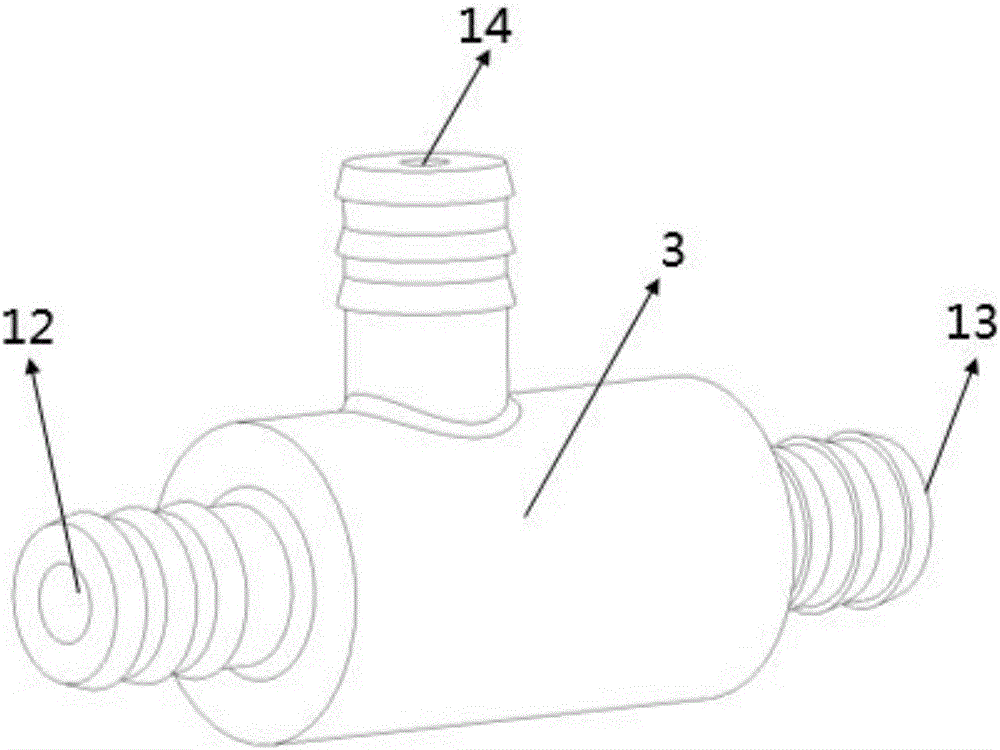

[0037] The coolant tank 1 includes a water return port E22, a water return port G24 and a water outlet F23; the micropump group 5 includes a first micropump 501, a second micropump 502, a micropump group water inlet A15, a micropump group water outlet C16 and The water outlet B17 of the micropump group; the jet cavity 3 includes a jet cavity inlet 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com