Thermal control system and application in a hydrogen energy storage system

A thermal control and hydrogen energy storage technology, applied in fuel cell heat exchange, fuel cells, electrical components, etc., can solve the problems of low energy conversion efficiency, low heat utilization rate of hydrogen energy storage system, and inability to choose cooling loops, etc. To achieve the effect of improving heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

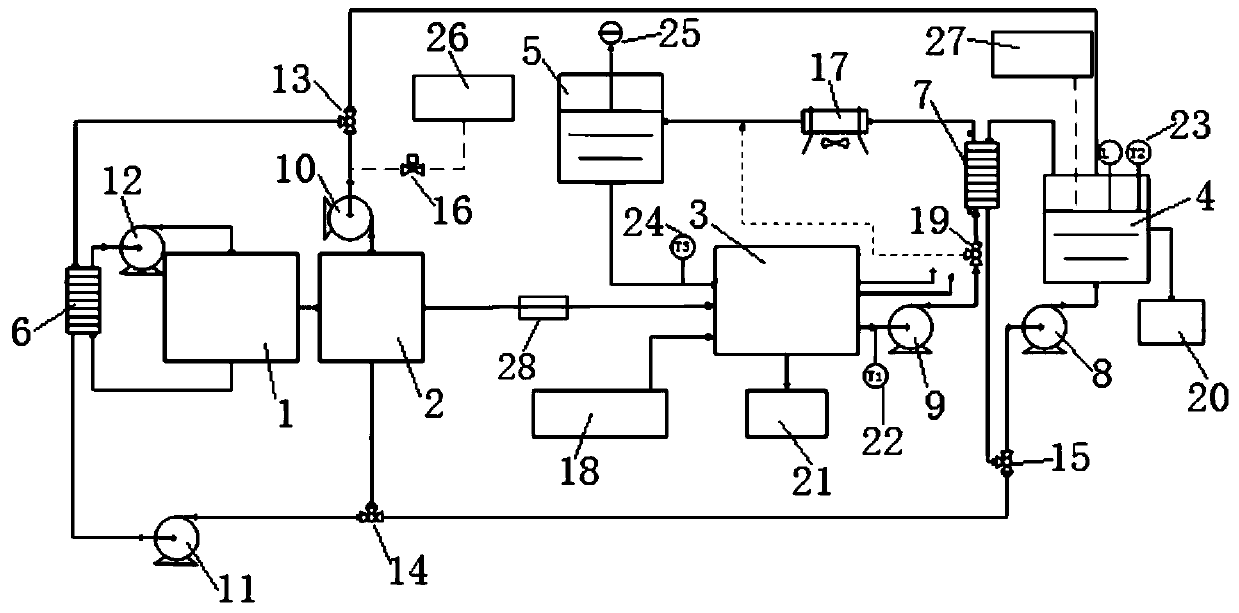

[0051] This implementation provides a thermal control system in a hydrogen energy storage system, such as figure 1 As shown, the hydrogen production device 1, the hydrogen storage device 2 and the hydrogen power generation device 3 connected in sequence are included, and the hydrogen production device 1, the hydrogen storage device 2 and the hydrogen power generation device 3 can all be selected according to needs. In this embodiment, the production The hydrogen device 1 is an alkaline electrolyzer electrolysis water hydrogen production device, the hydrogen storage device 2 is an alloy hydrogen storage tank, and the hydrogen power generation device 3 is a water-cooled proton exchange membrane fuel cell. In another embodiment, the hydrogen production device 1 is a proton exchange Membrane electrolyzer electrolysis water hydrogen production device or solid oxide electrolyzer electrolysis water hydrogen production device, the hydrogen storage device 2 is a steel cylinder hydrogen ...

Embodiment 2

[0076] Embodiment 2 The method of using the thermal control system in the hydrogen energy storage system of the present invention

[0077] Specifically include the following steps:

[0078] S1, using two sets of hydrogen production capacity of 40Nm 3 / h, the mass fraction is 30% KOH solution alkaline electrolyzer composition hydrogen production device, start the hydrogen production device, collect the temperature of the electrolyte in it and the temperature of tap water in the first liquid storage tank, when the temperature of tap water detected When it is higher than the temperature of the electrolyte, start the first water circulation pump, the fourth circulation pump and the fifth circulation pump, and open the first shut-off valve, the second shut-off valve and the third shut-off valve, so that the tap water passes through the plate heat exchanger and the hydrogen production The device exchanges heat and heats up the electrolyte; when the temperature of the electrolyte is...

Embodiment 3

[0081] Embodiment 3 The application method of the thermal control system in the hydrogen energy storage system of the present invention

[0082] Specifically include the following steps:

[0083] S1, using two sets of hydrogen production capacity of 40Nm 3 / h, the electrolyte is a hydrogen production device composed of Nafion's solid electrolyte electrolyzer, start the hydrogen production device, collect the temperature of the solid electrolyte in it and the temperature of the tap water in the first liquid storage tank, when the temperature of the detected tap water is greater than that of the solid electrolyte temperature, start the first water circulation pump, the fourth circulation pump and the fifth circulation pump, and open the first shut-off valve, the second shut-off valve and the third shut-off valve, so that the tap water can exchange heat with the hydrogen production device through the plate heat exchanger, Heat up the electrolytic cell; when the temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com