New energy motor rotor structure

A technology of rotor structure and motor, applied in the direction of electric components, magnetic circuit shape/style/structure, synchronous machine, etc., can solve the problems of mechanical wear, motor burnout, loud noise, etc., to improve starting performance, reduce cost, The effect of reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

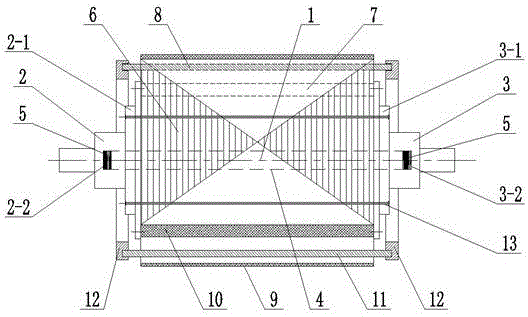

[0012] Below in conjunction with accompanying drawing, the present invention is further described;

[0013] In the drawings: the new energy motor rotor structure, including the rotor shaft 1; the rotor shaft 1 includes the front shaft 2 and the rear shaft 3; the front shaft 2 is provided with a first end plate 2-1 and a first hole 2-2; the rear axle 3 is provided with a second end plate 3-1 and a second hole 3-2; a small hole is provided between the first hole 2-2 and the second hole 3-2 shaft 4; a spring 5 is set between the small shaft 4 and the front shaft 2 and the rear shaft 3; a rotor punch 6 is set between the first end plate 2-1 and the second end plate 3-1; The rotor punch 6 is provided with a first through slot 7 and a second through slot 8, and a carbon fiber layer 9 is provided on the outer wall; the carbon fiber layer 9 has high temperature resistance, wear resistance and insulation performance, and prevents the motor from running at high speed. Next, the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com