Composite material for removing fluorinion in water and preparation method thereof

A composite material and water removal technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems that affect the efficient adsorption of fluoride ions by activated carbon, limited adsorption capacity of activated carbon to fluorine, and poor adsorption performance. Achieve the effect of fast adsorption speed, stable adsorption effect and large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

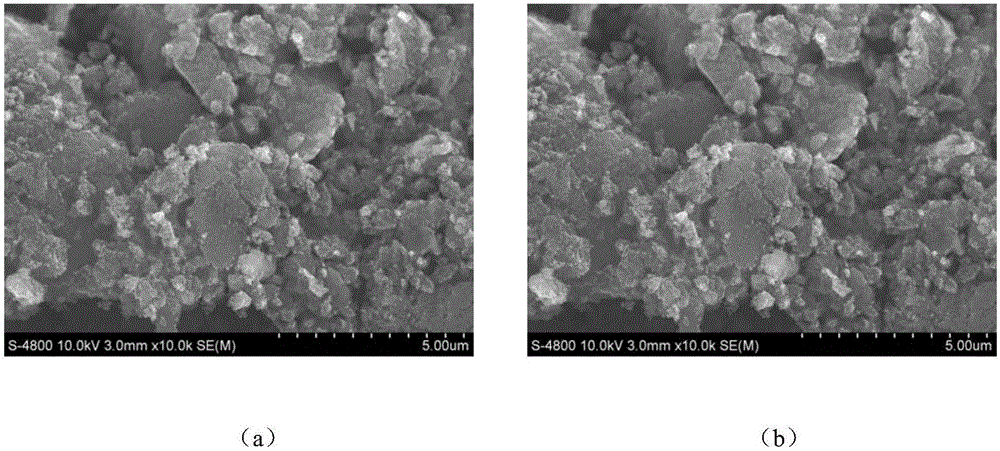

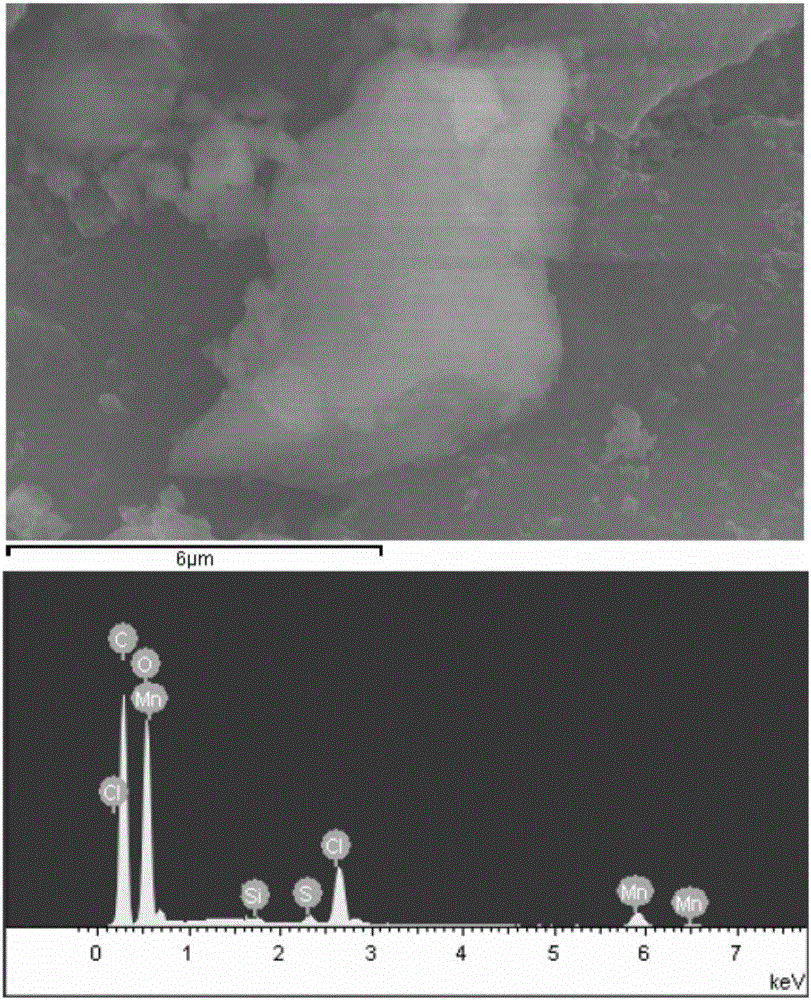

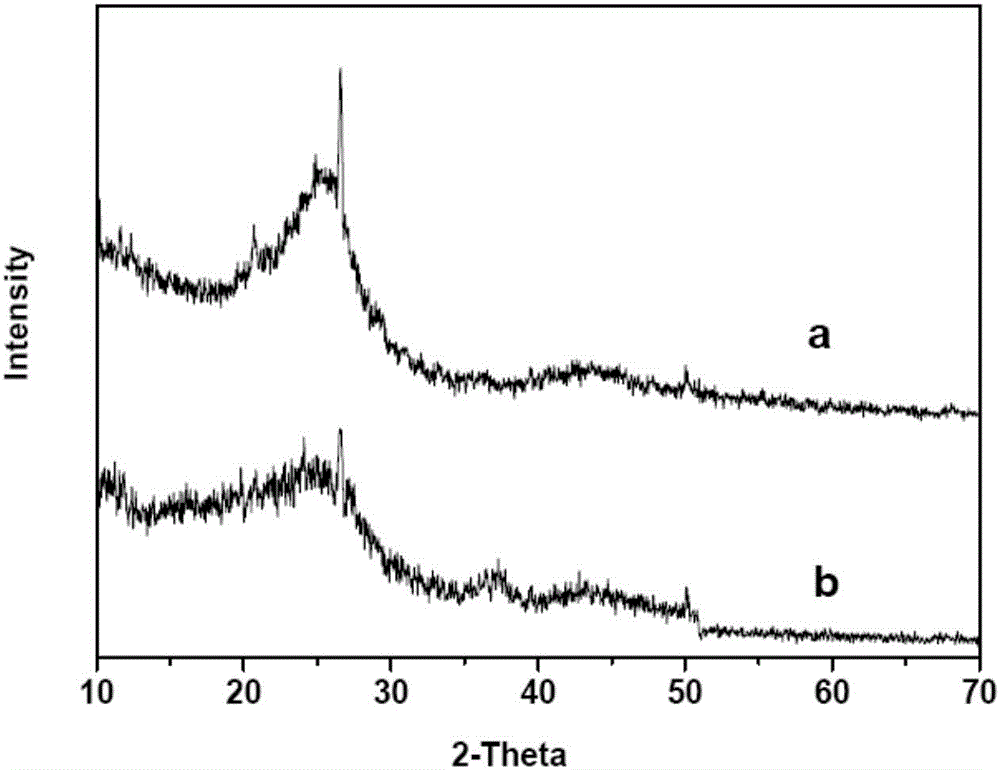

[0053] A composite material for removing fluorine ions in water, the composite material is a composite of manganese dioxide and activated carbon, wherein the manganese dioxide is supported on the surface of the activated carbon. There are pores on the surface of the composite material, and the specific surface area of the composite material is 802.51m 2 / g.

[0054] A method for preparing a composite material for removing fluoride ions in water, comprising:

[0055] (1) Activated carbon pretreatment: get the activated carbon particles with a particle size of 20 meshes, rinse them twice with deionized water, then dry them for later use;

[0056] (2) Manganese acetate solution is prepared: get manganese acetate tetrahydrate and join in distilled water for stirring and dissolving to obtain manganese acetate solution; the concentration of the prepared manganese acetate solution is 0.2mol / L;

[0057] (3) Take the activated carbon after the above-mentioned pretreatment with the ...

Embodiment 2

[0061] A composite material for removing fluorine ions in water, the composite material is a composite of manganese dioxide and activated carbon, wherein the manganese dioxide is supported on the surface of the activated carbon. There are pores on the surface of the composite material, and the specific surface area of the composite material is 997.30m 2 / g.

[0062] A method for preparing a composite material for removing fluoride ions in water, comprising:

[0063] (1) Activated carbon pretreatment: get the activated carbon particles with a particle size of 40 meshes, rinse them repeatedly with deionized water for 3 times, then dry them for later use;

[0064] (2) Manganese acetate solution is prepared: get manganese acetate tetrahydrate and join in distilled water for stirring and dissolving to obtain manganese acetate solution; the concentration of the prepared manganese acetate solution is 0.8mol / L;

[0065] (3) Take the activated carbon after the above-mentioned pretr...

Embodiment 3

[0069] A composite material for removing fluoride ions in water, the composite material is a composite of manganese dioxide and activated carbon, wherein the manganese dioxide is supported on the surface of the activated carbon. There are pores on the surface of the composite material, and the specific surface area of the composite material is 914.17m 2 / g.

[0070] A method for preparing a composite material for removing fluoride ions in water, comprising:

[0071] (1) Activated carbon pretreatment: take the activated carbon particles with a particle size of 30 meshes, rinse them twice with deionized water, and then dry them for later use;

[0072] (2) Manganese acetate solution is prepared: get manganese acetate tetrahydrate and join in distilled water for stirring and dissolving to obtain manganese acetate solution; the concentration of the prepared manganese acetate solution is 0.5mol / L;

[0073] (3) Take the activated carbon after the above-mentioned pretreatment with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com