Apparatus and method for separating styrene from hydrocarbons mixture

A hydrocarbon mixture, styrene technology, applied in the purification/separation of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., can solve the problems of long separation process, high energy consumption, high process energy consumption, and reduce equipment investment. , the effect of reducing heat load and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

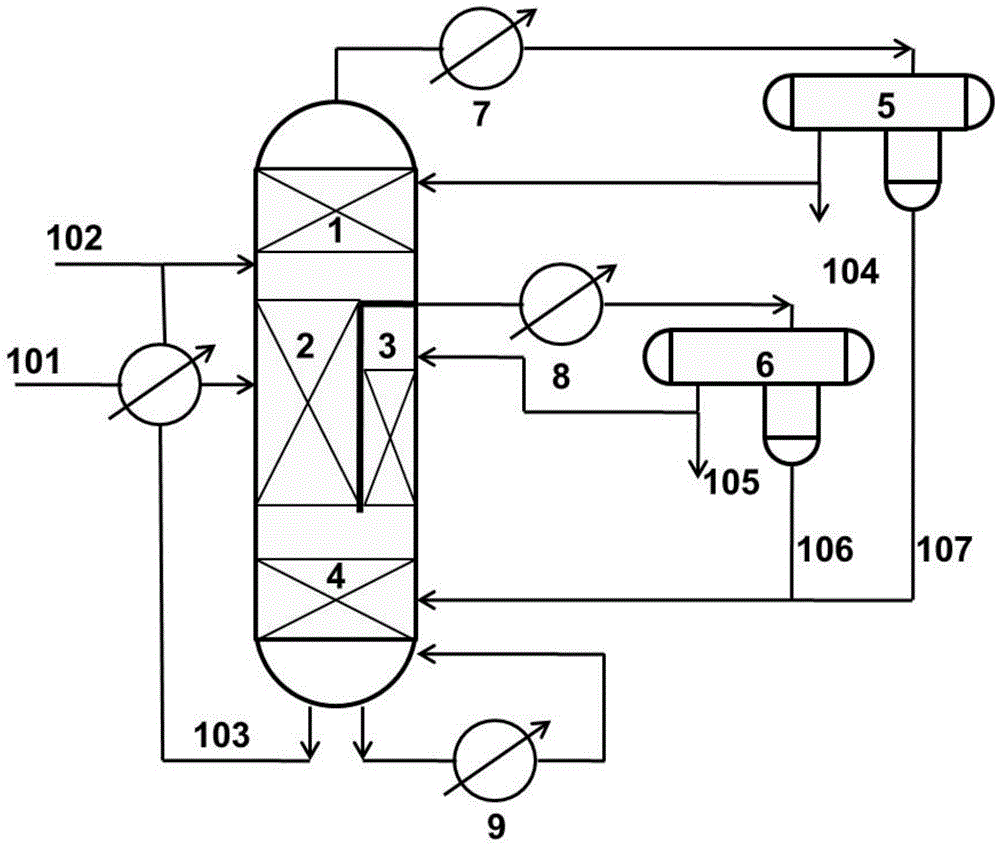

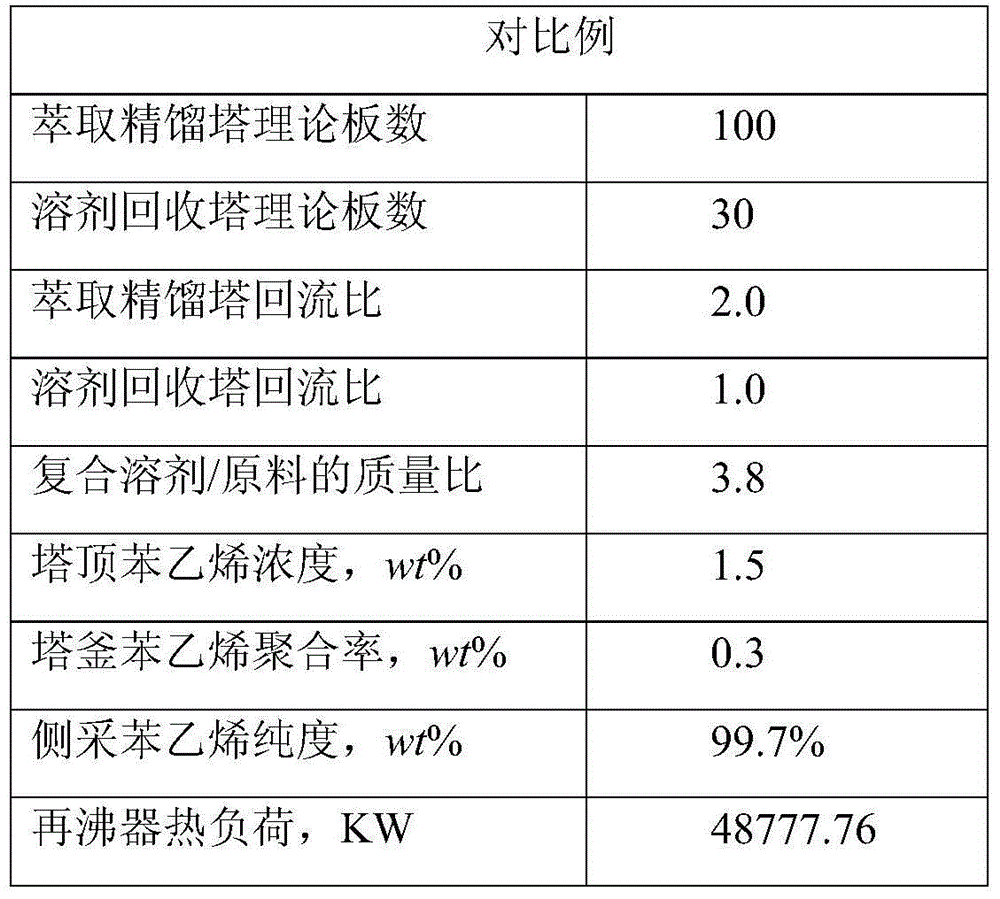

[0038] Based on a styrene plant with a production capacity of 150,000 tons / year, a dividing wall extractive distillation column is used to separate styrene from hydrocarbon mixtures. The structure and device flow of the dividing wall distillation column are as follows figure 1 shown. The ratio of the cross-sectional area of the extractive distillation section to the cross-sectional area of the solvent recovery section in the extractive distillation column is 1.5:1, and the height ratio of the common rectification section, the extractive distillation section and the common stripping section is 35:45: 10. After installing the trays, the number of theoretical plates in the common rectification section is 35; the number of theoretical plates in the extractive distillation section is 45; the number of theoretical plates in the solvent recovery section is 25; The inlet position of the mixed hydrocarbon raw material is set on the 10th plate from top to bottom in the extractive d...

Embodiment 2

[0042] Adopt the device and method among the embodiment 1 from pyrolysis gasoline C 8 Styrene is recovered in the distillate, the difference is: the ratio of the cross-sectional area of the extractive rectification section in the extractive distillation tower to the cross-sectional area of the solvent recovery section is 1.7:1, and the common rectification section, the extractive rectification section and the common The height ratio of the stripping section is 30:35:20. After installing the trays, there are 30 theoretical plates in the extraction and rectification section, 25 theoretical plates in the solvent recovery section, 30 theoretical plates in the public rectification section, 20 theoretical plates in the public stripping section, and a top reflux ratio of 2.5 , the side line reflux ratio is 1.8, and other conditions are the same as before. Under the conditions of controlling the purity of styrene to 99.7wt% and the recovery rate to 95wt%, the results of extractiv...

Embodiment 3

[0044] Adopt the device and method among the embodiment 1 from pyrolysis gasoline C 8 Styrene is recovered in the distillate, the difference is: the ratio of the cross-sectional area of the extractive rectification section in the extractive distillation column to the cross-sectional area of the solvent recovery section is 1.8:1, the common rectification section, the extractive rectification section and the common The height ratio of the stripping section is 25:40:20. After installing the trays, there are 25 theoretical plates in the public rectification section, 40 theoretical plates in the extractive distillation section, 20 theoretical plates in the public stripping section, 30 theoretical plates in the solvent recovery section, and a top reflux ratio of 1.2 , the side line reflux ratio is 1.5, the mass ratio of composite solvent / raw material is 5, and all the other conditions are the same as in Example 2. Under the conditions of controlling the purity of styrene to 99....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com