Preparation method of lycium barbarum polysaccharides

A technology of wolfberry polysaccharide and wolfberry fruit, which is applied in the field of food processing, can solve the problems of low polysaccharide extraction efficiency, complicated extraction process, and destruction of polysaccharide structure, and achieve the effects of not easy to get damp and agglomerated, high recovery rate, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

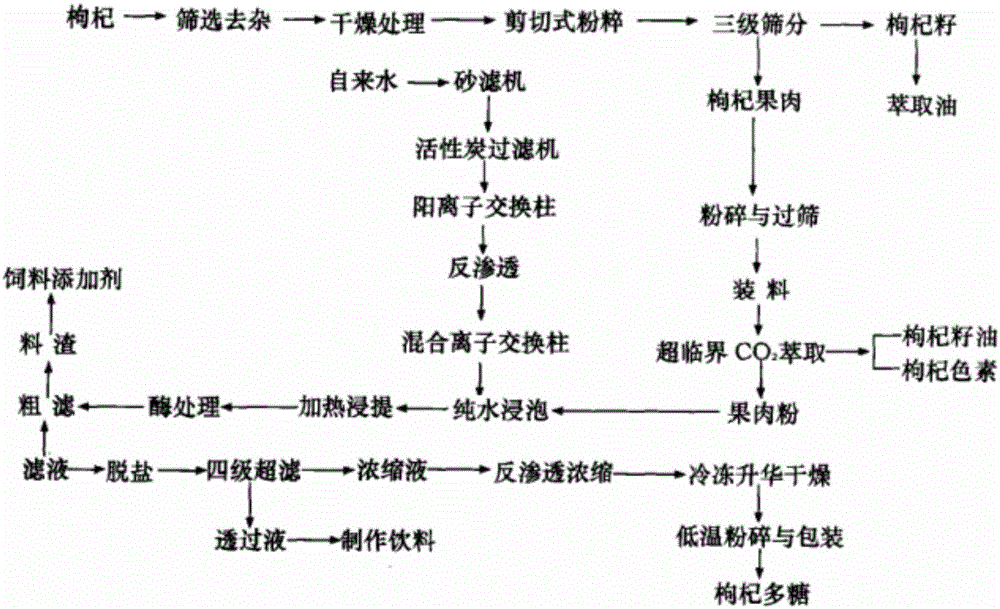

Method used

Image

Examples

Embodiment 1

[0053] A preparation method of Lycium barbarum polysaccharide, comprising the following steps:

[0054] 1) Screening and removing impurities:

[0055] The wolfberry fruit is screened to remove impurities and diseased fruits; preferably, the wolfberry fruit is a high-quality summer fruit produced in Zhongning, Ningxia;

[0056] 2) drying;

[0057] Drying and dehydrating the separated Lycium barbarum fruit with hot air, the dry Lycium barbarum moisture is 6%;

[0058] 3) Crushing and separation:

[0059] The dried wolfberry fruit is crushed by a coarse particle crusher, and then the pulp powder and wolfberry seeds are separated through a three-stage sieve;

[0060] 4) Extraction:

[0061] After passing the pulp powder through a 20-mesh sieve, supercritical CO 2 Extraction; the fluid extraction pressure is 27MPa, the extraction temperature is 50°C, and the extraction time is 2.5h;

[0062] 5) Soaking:

[0063] Put the extracted pulp powder into an extraction tank, then add...

Embodiment 2

[0077] A preparation method of Lycium barbarum polysaccharide, comprising the following steps:

[0078] 2) Screening and removing impurities:

[0079] The wolfberry fruit is screened to remove impurities and diseased fruits; preferably, the wolfberry fruit is a high-quality summer fruit produced in Zhongning, Ningxia;

[0080] 2) drying;

[0081] Drying and dehydrating the separated Lycium barbarum fruit with hot air, the dry Lycium barbarum moisture is 7%;

[0082] 3) Crushing and separation:

[0083] The dried wolfberry fruit is crushed by a coarse particle crusher, and then the pulp powder and wolfberry seeds are separated through a three-stage sieve;

[0084] 4) Extraction:

[0085] After passing the pulp powder through a 20-mesh sieve, supercritical CO 2 Extraction; the fluid extraction pressure is 26MPa, the extraction temperature is 50°C, and the extraction time is 2h;

[0086] 5) Soaking:

[0087] Put the extracted pulp powder into an extraction tank, then add p...

Embodiment 3

[0101] A preparation method of Lycium barbarum polysaccharide, comprising the following steps:

[0102] 3) Screening and removing impurities:

[0103] The wolfberry fruit is screened to remove impurities and diseased fruits; preferably, the wolfberry fruit is a high-quality summer fruit produced in Zhongning, Ningxia;

[0104] 2) drying;

[0105] Drying and dehydrating the separated Lycium barbarum fruit with hot air, the dry Lycium barbarum moisture content is 5%;

[0106] 3) Crushing and separation:

[0107] The dried wolfberry fruit is crushed by a coarse particle crusher, and then the pulp powder and wolfberry seeds are separated through a three-stage sieve;

[0108] 4) Extraction:

[0109] After passing the pulp powder through a 20-mesh sieve, supercritical CO 2 Extraction; the fluid extraction pressure is 28MPa, the extraction temperature is 55°C, and the extraction time is 3h;

[0110] 5) Soaking:

[0111] Put the extracted pulp powder into an extraction tank, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com