Polystyrene foam decorative sheet and manufacturing method thereof

A technology of polystyrene foam and manufacturing method, which is applied in the field of decorative boards, can solve problems such as poor toughness, environmental protection, and high brittleness of decorative boards, and achieve the effects of improving compatibility and binding force, improving toughness and degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

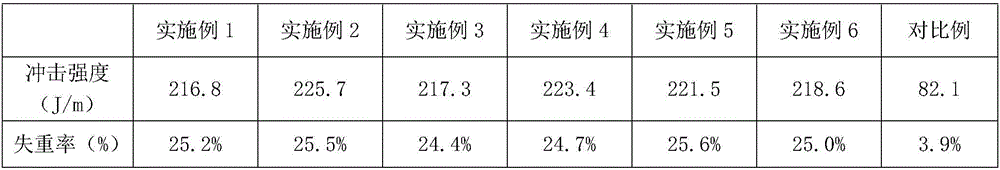

Examples

Embodiment 1

[0027] Follow the steps below to make a styrofoam trim panel:

[0028] (1) Wash the pumpkin skin and air-dry it for 5 days, cut it into small pieces of 5cm×1cm, put it into 5 times the weight of distilled water, take it out after soaking for 24 hours, and transfer it to a continuous steam blasting machine for blasting treatment to obtain the crude pumpkin skin. Fiber, the steam pressure is 2MPa, and the holding time is 150s;

[0029] (2) Add the pumpkin skin crude fiber obtained in step (1) into a sulfuric acid solution with a mass concentration of 20%, the mass ratio of the pumpkin skin crude fiber to the sulfuric acid solution is 1:12, heat to 60°C and stir for 1.5 hours, take out Finally, wash with deionized water until neutral, beat with an iron rod, turn over once every 5 minutes, repeat 5 times, soak and wash with distilled water for 5 minutes, and obtain pumpkin skin fibers after drying;

[0030] (3) the pumpkin peel fiber that step (2) obtains is added in the sodium h...

Embodiment 2

[0034] Follow the steps below to make a styrofoam trim panel:

[0035](1) Wash the pumpkin skin and air-dry it for 5 days, cut it into small pieces of 5cm×1cm, put it into 5 times the weight of distilled water, take it out after soaking for 24 hours, and transfer it to a continuous steam blasting machine for blasting treatment to obtain the crude pumpkin skin. Fiber, the steam pressure is 2MPa, and the holding time is 150s;

[0036] (2) Add the pumpkin skin crude fiber obtained in step (1) into a sulfuric acid solution with a mass concentration of 20%, the mass ratio of the pumpkin skin crude fiber to the sulfuric acid solution is 1:12, heat to 60°C and stir for 1.5 hours, take out Finally, wash with deionized water until neutral, beat with an iron rod, turn over once every 5 minutes, repeat 5 times, soak and wash with distilled water for 5 minutes, and obtain pumpkin skin fibers after drying;

[0037] (3) the pumpkin peel fiber that step (2) obtains is added in the sodium hy...

Embodiment 3

[0041] Follow the steps below to make a styrofoam trim panel:

[0042] (1) Wash the pumpkin skin and air-dry it for 5 days, cut it into small pieces of 5cm×1cm, put it into 5 times the weight of distilled water, take it out after soaking for 24 hours, and transfer it to a continuous steam blasting machine for blasting treatment to obtain the crude pumpkin skin. Fiber, the steam pressure is 2MPa, and the holding time is 150s;

[0043] (2) Add the pumpkin skin crude fiber obtained in step (1) into a sulfuric acid solution with a mass concentration of 20%, the mass ratio of the pumpkin skin crude fiber to the sulfuric acid solution is 1:12, heat to 60°C and stir for 1.5 hours, take out Finally, wash with deionized water until neutral, beat with an iron rod, turn over once every 5 minutes, repeat 5 times, soak and wash with distilled water for 5 minutes, and obtain pumpkin skin fibers after drying;

[0044] (3) the pumpkin peel fiber that step (2) obtains is added in the sodium h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com