Tough polyethylene powder paint containing nano carbon fiber grafted activated organobentonite and preparation method thereof

A nano carbon fiber and polyethylene powder technology, applied in powder coatings, coatings and other directions, can solve the problems of easy cracking on the surface, poor mechanical strength, poor adhesion of the coating film, etc. Compatibility, modification effect improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

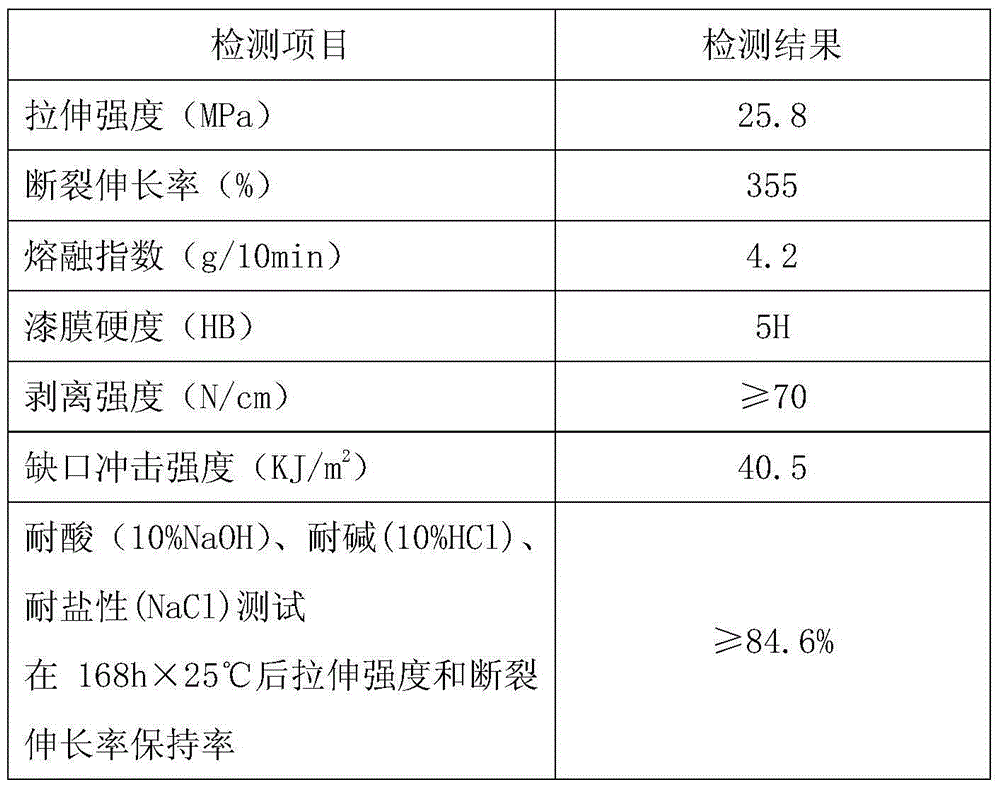

Examples

Embodiment

[0011] The coating of this embodiment is made of the following raw materials by weight: 450 mesh organic bentonite 6, carboxymethyl cellulose 1.5, carbon nanofiber 0.4, rosin glyceride 4, silane coupling agent KH-5502.5, pigment 6, polyethylene 48 , potassium permanganate 0.4, acrylonitrile-butadiene-styrene resin 12, acrylate leveling agent 1.5, antioxidant 2.5.

[0012] The preparation method of this powder coating is:

[0013] (1) First put the organic bentonite micropowder into an aqueous solution with a concentration of 35g / L prepared by potassium permanganate, soak for 60min, then filter, wash the filtrate with water for 3 times, add 0.6 parts by weight of silane coupling agent KH -550, carbon nanofibers, heating to 75°C, stirring and mixing at high speed for 1.8h, to obtain carbon nanofiber grafted activated organic bentonite micropowder for later use;

[0014] (2) Dissolve carboxymethyl cellulose in 12 parts by weight of water, then pulverize polyacrylonitrile fiber i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com