Building asphalt and preparing method thereof

A technology of building asphalt and deoiled asphalt, which is applied in the direction of construction, building components, building structures, etc., can solve the problems of low final product yield, small margin of softening point index, and affecting the ductility of building asphalt, and achieve production The effect of low cost, low requirements, and small equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

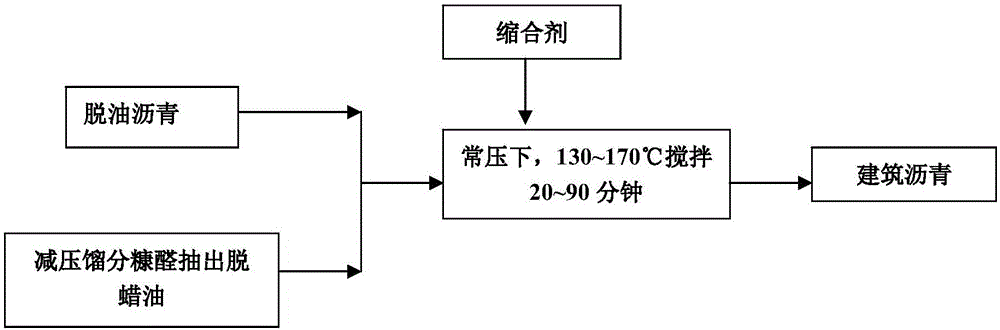

[0024] In this embodiment, the building asphalt is prepared by chemical condensation reaction using deoiled asphalt and dewaxed oil extracted from four-line furfural reduction. The preparation method includes the following steps:

[0025] (1) Get the reaction raw materials according to the mass percentage: deoiled asphalt (2) 90%, extract 10% of the dewaxed oil by subtracting four-line furfural, add respectively in the three-necked flask with stirring device, after stirring and mixing evenly, stir while stirring Add the polyphosphoric acid of consumption as in table 1, stir and mix evenly;

[0026] (2) Condensation reaction was carried out at normal pressure and temperature of 140° C. for 40 minutes. The property analysis of the obtained product is shown in Table 1.

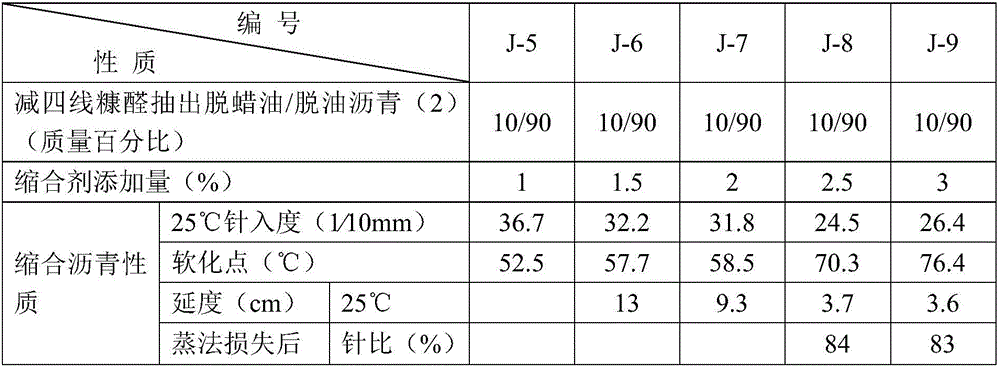

[0027] Analysis of building asphalt properties in the present embodiment of table 1

[0028]

[0029] It can be seen from Table 1 that the construction asphalt prepared in this example complies with the No. 3...

Embodiment 2

[0031] In this embodiment, the building asphalt is prepared by chemical condensation reaction using deoiled asphalt and dewaxed oil extracted from four-line furfural reduction. The preparation method includes the following steps:

[0032] (1) Get the reaction raw materials according to the mass percentage: deoiled asphalt (2) 85%, extract 15% of the dewaxed oil by subtracting four-line furfural, add respectively in the three-necked flask with stirring device, after stirring and mixing evenly, stir while stirring Add the polyphosphoric acid of consumption as in table 2, stir and mix evenly;

[0033] (2) Condensation reaction was carried out at normal pressure and temperature of 140° C. for 40 minutes. The property analysis of the obtained product is shown in Table 2.

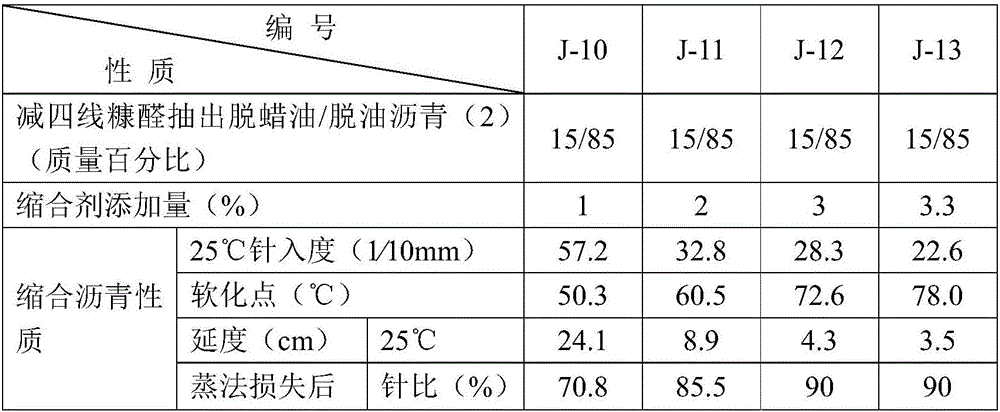

[0034] Analysis of building asphalt properties in the present embodiment of table 2

[0035]

[0036] It can be seen from Table 2 that the construction asphalt prepared in this example complies with the No. 3...

Embodiment 3

[0038] In this embodiment, the building asphalt is prepared by chemical condensation reaction using deoiled asphalt and dewaxed oil extracted from four-line furfural reduction. The preparation method includes the following steps:

[0039] (1) Get the reaction raw materials according to the mass percentage: deoiled asphalt (2) 80%, extract 20% of the dewaxed oil by subtracting four-line furfural, add respectively in the three-necked flask with stirring device, after stirring and mixing evenly, stir while stirring Add the polyphosphoric acid of consumption as in table 3, stir and mix evenly;

[0040] (2) Condensation reaction was carried out at normal pressure and temperature of 140° C. for 40 minutes. The property analysis of the obtained product is shown in Table 3.

[0041] Analysis of building asphalt properties in the present embodiment of table 3

[0042]

[0043] It can be seen from Table 3 that the construction asphalt prepared in this example complies with the No. 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com