Preparation process of ultraviolet-proof multifunctional textile fabric

An anti-ultraviolet, textile fabric technology, applied in textiles and papermaking, liquid repellent fibers, anti-color pollution/anti-fouling fibers, etc. Not resistant to washing and other problems, to achieve good anti-ultraviolet function, long-term anti-ultraviolet, good three-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

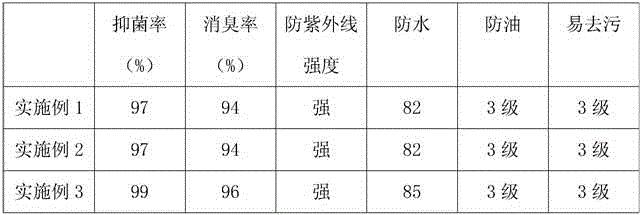

Embodiment 1

[0018] A preparation process for anti-ultraviolet multifunctional textile fabrics. After three steps of anti-ultraviolet treatment process, padding finishing process and drying, the processing process of textile fabrics is completed. During padding and finishing, the textile fabrics are placed in nano-finishing liquid Intermediate padding and finishing; the specific steps are as follows:

[0019] (1) Anti-ultraviolet treatment process: select the anti-ultraviolet powder to prepare the anti-ultraviolet padding solution, put the yarn-dyed fabric in the anti-ultraviolet padding solution at 80°C for 3 hours, and then tie it again, the excess rate is 65%. The amount of anti-ultraviolet powder added is 8g / L, the particle diameter of anti-ultraviolet powder is 15nm, and the specific gravity is 1.0g / m 3 ;

[0020] (2) Padding and shaping finishing process: two paddings are carried out during the padding and shaping finishing, and the rolling liquid rate of the first padding is 50%, a...

Embodiment 2

[0025] A preparation process for anti-ultraviolet multifunctional textile fabrics. After three steps of anti-ultraviolet treatment process, padding finishing process and drying, the processing process of textile fabrics is completed. During padding and finishing, the textile fabrics are placed in nano-finishing liquid Intermediate padding and finishing; the specific steps are as follows:

[0026] (1) Anti-ultraviolet treatment process: select the anti-ultraviolet powder to prepare the anti-ultraviolet padding solution, put the yarn-dyed fabric in the anti-ultraviolet padding solution at 95°C for 5 hours, and then tie it again. The excess rate is 75%. The amount of anti-ultraviolet powder added is 12g / L, the particle diameter of anti-ultraviolet powder is 25nm, and the specific gravity is 1.2g / m 3 ;

[0027] (2) Padding and shaping finishing process: two paddings are carried out during the padding and shaping finishing, and the rolling liquid rate of the first padding is 60%, ...

Embodiment 3

[0032] A preparation process for anti-ultraviolet multifunctional textile fabrics. After three steps of anti-ultraviolet treatment process, padding finishing process and drying, the processing process of textile fabrics is completed. During padding and finishing, the textile fabrics are placed in nano-finishing liquid Intermediate padding and finishing; the specific steps are as follows:

[0033] (1) Anti-ultraviolet treatment process: select the anti-ultraviolet powder to prepare the anti-ultraviolet padding solution, put the yarn-dyed fabric in the anti-ultraviolet padding solution at 87°C for 4 hours, then tie it again, the excess rate is 70%, The amount of anti-ultraviolet powder added is 10g / L, the particle diameter of anti-ultraviolet powder is 20nm, and the specific gravity is 1.1g / m 3 ;

[0034] (2) Padding and shaping finishing process: Carry out twice padding altogether during padding and shaping finishing, and the rolling liquid rate of padding for the first time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com