A preparation method of filler composition, filler composition and paper

A composition and mixture technology, applied in the field of papermaking, can solve the problems of reduced tear strength of paper, unable to meet the bulk thickness, reduced paper thickness, etc., and achieve the effects of reducing the bonding area, improving the retention rate, and improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

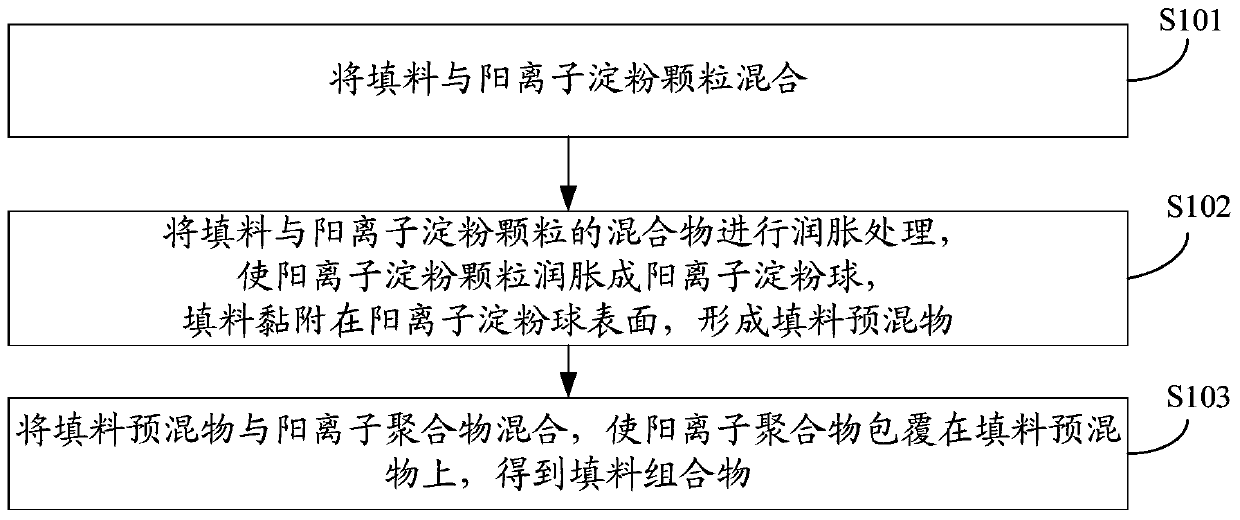

[0039] refer to figure 1 , the embodiment of the present invention provides a kind of preparation method of filler composition, comprises the following steps:

[0040] Step S101: mixing fillers with cationic starch granules;

[0041] Fillers are some basic water-insoluble solid particles added to the pulp during the papermaking process, which can improve the opacity, brightness, smoothness, printing adaptability (such as improving absorption, ink absorption), softness, and uniformity of the paper. and dimensional stability; cationic starch is the introduction of tertiary amino groups or quaternary ammonium groups into starch macromolecules to endow starch with cationic properties.

[0042] Step S102: Swelling the mixture of the filler and the cationic starch granules, so that the cationic starch granules swell into cationic starch spheres, and the filler adheres to the surface of the cationic starch spheres to form a filler premix;

[0043] The mixture of fillers and cationi...

Embodiment 1

[0088] Get 500g mass percent concentration and be 20% GCC, under agitation, add cationic starch granules relative to GCC absolute dry weight 1%, the degree of substitution of cationic starch granules is 0.015; GCC and cationic starch granule mixed solution temperature is raised to 50 degrees Celsius, and stirred for 0.5 hours to form a filler premix; under stirring, to the above filler premix, add 0.05% cationic guar gum relative to the absolute dry weight of GCC, and stir for 5 minutes, wherein the cationic The guar gum has a degree of substitution of 0.05 and a molecular weight of 500,000 to form a filler composition.

Embodiment 2

[0090] Get 500g mass percent concentration and be 20% GCC, under agitation, add cationic starch granules relative to GCC absolute dry weight 2%, the degree of substitution of cationic starch granules is 0.015; GCC and cationic starch granule mixed solution temperature is raised to 50 degrees Celsius, and stirred for 0.5 hours to form a filler premix; in the stirring state, add 0.1% cationic guar gum relative to the absolute dry weight of GCC to the above filler premix, and stir for 5 minutes, wherein, the cationic The guar gum has a degree of substitution of 0.1 and a molecular weight of 1,000,000 to form a filler composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com