Three-phase type tunnel construction ventilation control method

A technology of tunnel construction and control method, which is applied in mine/tunnel ventilation, pump control, engine control and other directions. It can solve the problems that the calculation result parameters have great influence and the optimal position may not be suitable for on-site installation, so as to shorten the approach to the site. time, the effect of improving environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

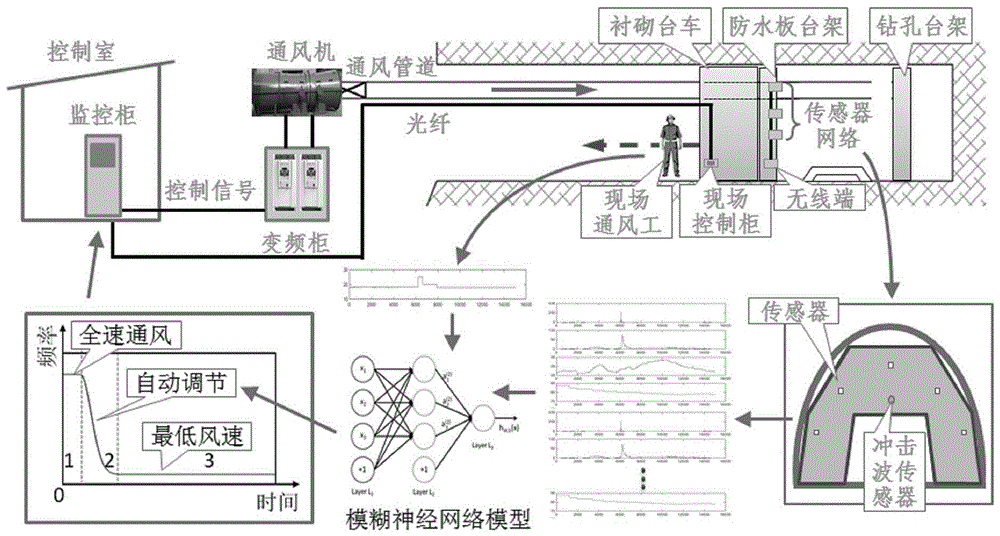

[0015] see figure 1 , the present invention proposes a three-stage tunnel construction ventilation control method based on sensor network and fuzzy neural network algorithm, its principle is as follows figure 1 shown.

[0016] Among them, the control system is composed of the monitoring cabinet located in the control room, the field control cabinet located in the lining trolley, the wireless end of the waterproof board platform and the sensor network at the front end of the waterproof board platform. The three-stage tunnel construction ventilation control algorithm runs in the monitoring cabinet.

[0017] The three-stage tunnel construction ventilation control method of the present invention adopts staged ventilation control to realize the automatic control of tunnel construction ventilation. The first stage: after the blasting is over, the fan enters the full-speed ventilation stage, and the blower will be blown as soon as possible under the maximum operating frequency (usua...

Embodiment 2

[0019] see figure 1 , figure 2 The difference between the three-stage tunnel construction ventilation control method of this embodiment and Embodiment 1 is that: further, the full-speed operation stage is excited by the shock wave sensor installed on the waterproof board platform. After the shock wave sensor detects that the blasting is completed, that is, after a certain time delay, it enters the full-speed operation stage.

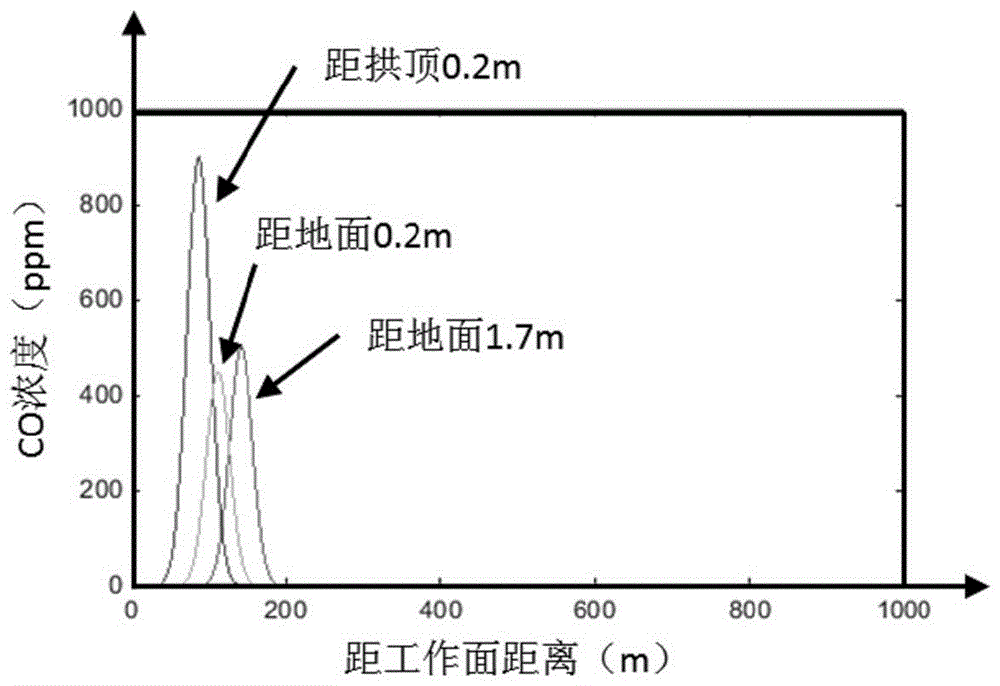

[0020] like figure 2 Shown is the CO concentration distribution curve at each vertical height at 100 meters from the face of the tunnel (where the flashing platform is located) obtained through simulation analysis. from figure 2 The following conclusions can be drawn: 1) Under the condition of ventilation, the gas concentration presents a Gaussian distribution in the axial direction; 2) When the peak value of the gas concentration passes through the waterproof board stand, the distance between the face and the waterproof board (the main working are...

Embodiment 3

[0022] see figure 1 , figure 2 , the three-stage tunnel construction ventilation control method of this embodiment is different from Embodiment 1 or Embodiment 2 in that: in the automatic adjustment stage, a fuzzy neural network algorithm is used to establish a fuzzy neural network model, and the automatic adjustment function is controlled by figure 1 The fuzzy neural network model shown in is completed. The model learns the sensor data collected and the fan operating frequency value obtained by the on-site ventilation workers, and obtains the control law of the on-site environmental parameters; the fuzzy neural network model includes a learning phase and a normal working phase: in the learning phase, the fuzzy neural network After the model learns the sample input (data collected by the sensor network after preprocessing) and the learning target (the operating frequency of the ventilator given by the ventilator), the learned connection weights are saved for calculation; In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com