Thin chip machining and pasting assembly method

An assembly method and thin chip technology, applied in the field of microelectronics, can solve the problems of complicated operation, many processes, and high price of cutting protective film, and achieve the effect of less process, easy debonding, and reduction of equipment precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

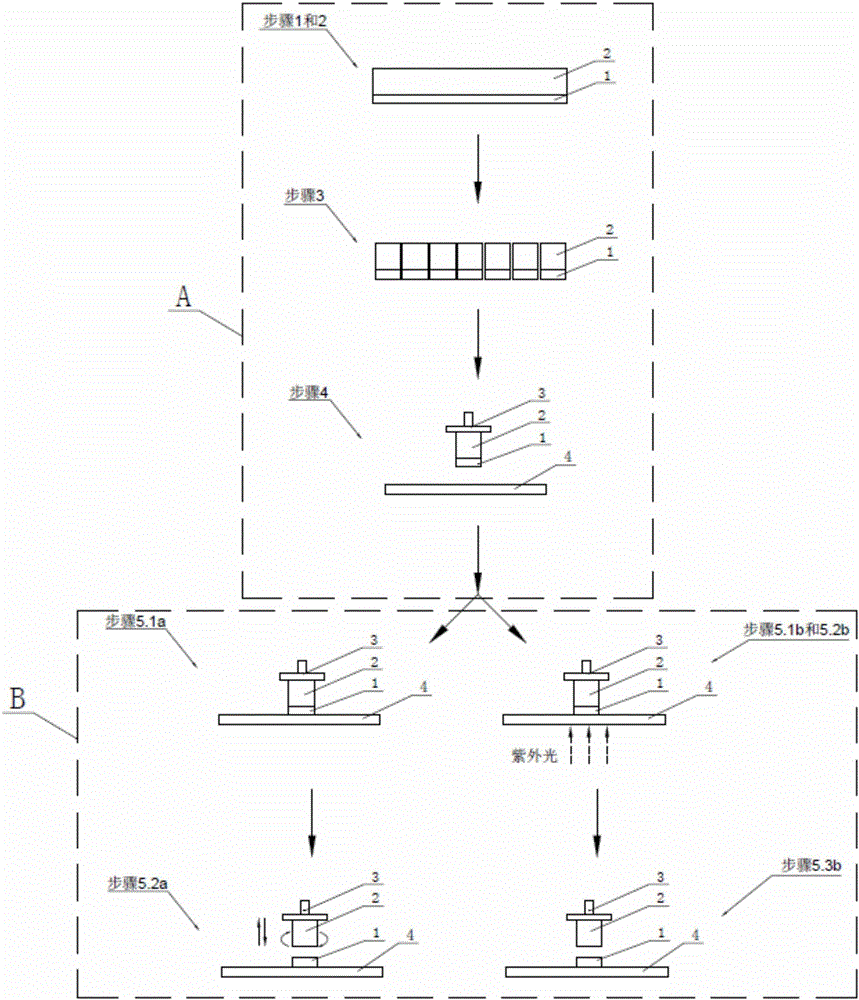

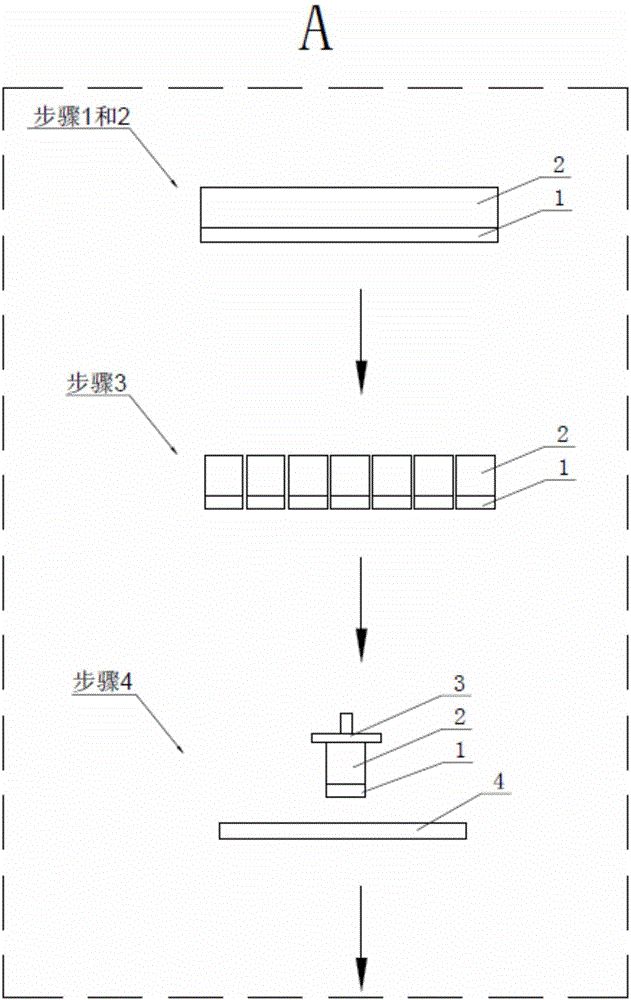

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] The invention provides a thin chip processing and patch assembly method, which includes:

[0036] Step 1, bonding the functional wafer 1 and the carrier wafer 2 through a bonding glue;

[0037] Step 2, thinning the functional wafer 1;

[0038] It is characterized in that: it also includes:

[0039] Step 3, cutting the functional wafer 1 and the carrier wafer 2 into several subunits; each subunit includes a small functional wafer 1 and a carrier wafer 2 .

[0040] Step 4, grabbing the carrier wafer 2 in the subunit by the clamping mechanism 3 and moving it to the corresponding substrate 4;

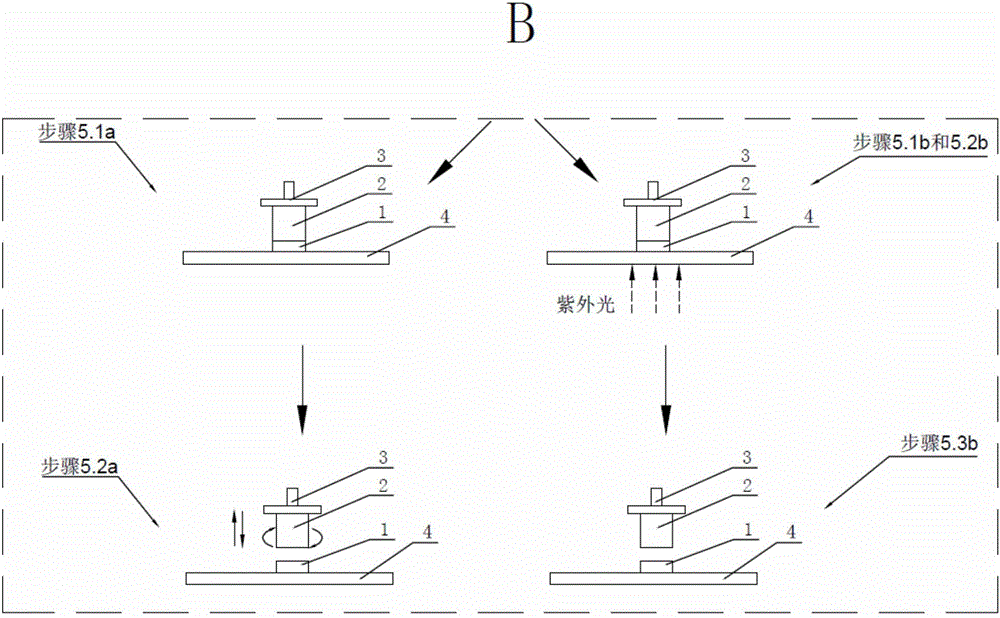

[0041] Step 5, the functional wafer 1 in the subunit is bonded to the substrate 4 , and the functional wafer 1 and the carrier wafer 2 are driven to debond during the process of pulling the clamping mechanism 3 away.

[0042] Said step 5 includes:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com