Adhesive, preparation method and application thereof

A technology of adhesives and initiators, applied in the direction of adhesives, non-polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problems that hinder the commercialization of ion gel adhesives, high price and toxicity, and achieve The effect of low cost, wide application and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The application also provides a kind of preparation method of described adhesive, comprising:

[0046] The raw materials are mixed and reacted to obtain the adhesive.

[0047] In an optional embodiment, the reaction comprises a heating reaction or an ultraviolet curing reaction;

[0048] In an optional embodiment, the temperature of the heating reaction is 60°C-80°C, and the time is 1h-24h;

[0049] In an optional embodiment, the ultraviolet curing reaction time is 5 min-60 min.

[0050] Optionally, the temperature of the heating reaction can be 60°C, 65°C, 70°C, 75°C, 80°C or any value between 60°C-80°C, and the time can be 1h, 2h, 4h, 6h, 8h, 10h, 12h, 14h, 16h, 18h, 20h, 22h, 24h or any value between 1h-24h; the UV curing reaction time can be 5min, 10min, 15min, 20min, 25min, 30min, 35min, 40min, 45min, 50min, 55min, 60min or any value between 5min-60min.

[0051] The application also provides a use of the adhesive for the production of optical products.

[0052...

Embodiment 1

[0055] The present embodiment provides a kind of adhesive and preparation method thereof, specifically as follows:

[0056] Mix 2.8g of acrylic acid, 1.2g of deep eutectic solution mixed with urea and choline chloride at a molar ratio of 2:1, and 79mg of 1-hydroxycyclohexyl phenyl ketone (PI184), and vacuum degas for 30s. After coating the precursor liquid on the substrate, it is cured by ultraviolet light. Light source power density is 50mW / cm 2 , time 10min.

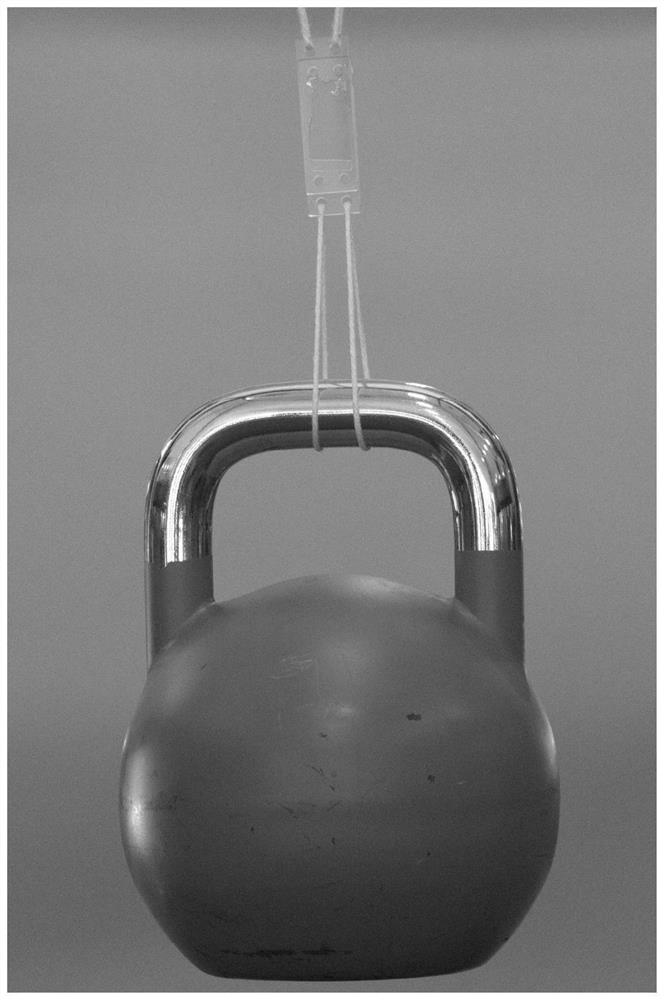

[0057] figure 1 Schematic photo of the performance of the adhesive obtained in Example 1 for lifting heavy objects (the bonding area of the adhesive is approximately 7 square centimeters, and the weight to be lifted weighs about 24 kg). figure 1 Show that the adhesive obtained by the present application has excellent adhesive properties.

Embodiment 2

[0059] The present embodiment provides a kind of adhesive and preparation method thereof, specifically as follows:

[0060] Mix 2.8g of acrylic acid, 1.2g of a deep eutectic solution of 1,4-butanediol and choline chloride at a molar ratio of 2:1 and 79mg of 1-hydroxycyclohexyl phenyl ketone (PI184), After vacuum degassing for 30s, the precursor liquid is coated on the substrate and cured by ultraviolet light. Light source power density is 50mW / cm 2 , time 10min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com