Distributed structure and control method of high voltage and high frequency electrostatic precipitation power supply inverting circuit

A technology of high-frequency inverter circuit and distributed structure, which is applied in the direction of electrical components, output power conversion device, AC power input conversion to DC power output, etc. Problems such as large harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

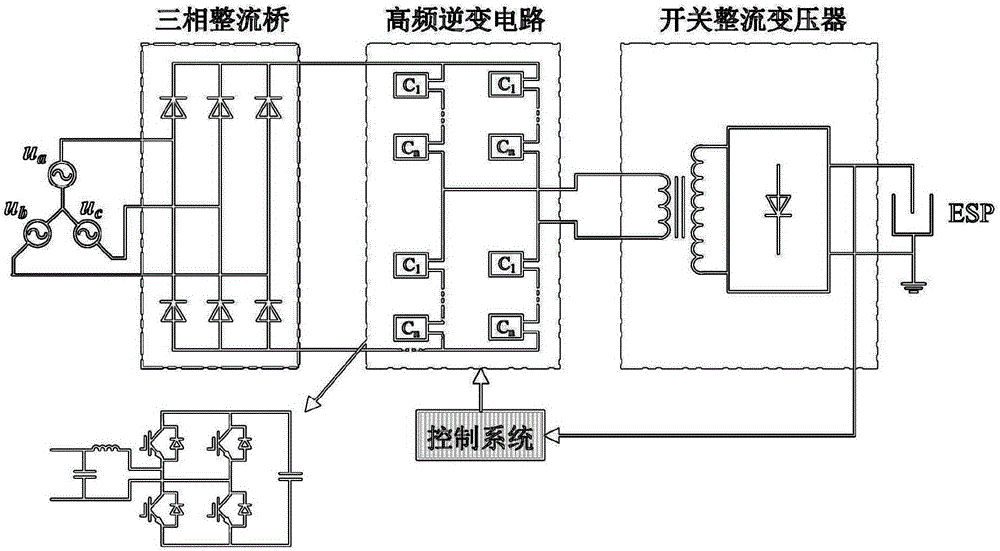

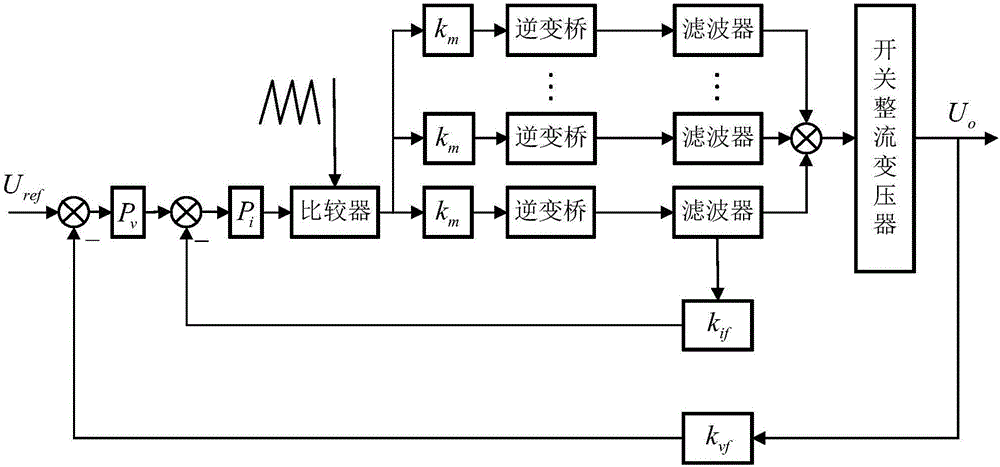

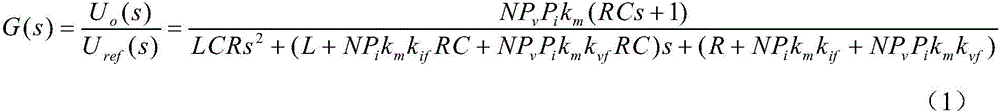

[0037] Embodiment 1: The high-voltage and high-frequency pulse power supply system is the core of the entire electrostatic precipitator power supply system, such as figure 1 As shown, it is mainly composed of three-phase rectifier bridge, high-frequency inverter circuit, switching rectifier transformer and control system. The high-frequency inverter circuit is a chain-type H-bridge multi-level inverter circuit; its working process is as follows: 380V The power frequency AC power supply outputs a stable DC voltage through the three-phase rectifier bridge, which is supplied to the chained H-bridge multi-level inverter circuit, and the chained H-bridge multi-level inverter circuit outputs the required AC pulses according to the real-time working conditions of the electrostatic precipitator After step-up and rectification by the switching rectifier transformer, the high-voltage DC pulse voltage is output to supply the electric field of the electrostatic precipitator, and the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com