Preparation method for green cake

A technology of green cake and mugwort leaves, which is applied in the forming of food, the function of food ingredients, and food ingredients as taste improvers. and other problems, to achieve the effect of beautiful appearance, increased crude fiber content, and helpful absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

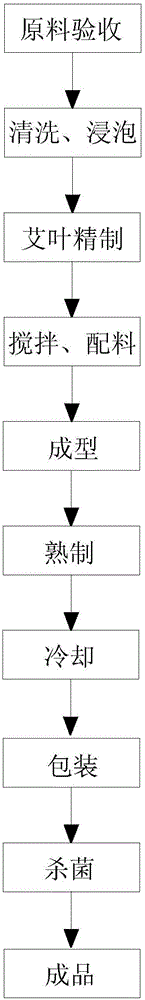

[0025] see figure 1 , a kind of preparation method of green cake, comprises the following steps:

[0026] 1) Raw material acceptance: select glutinous rice, rice and mugwort leaves harvested in the current year; select pig fat and edible vegetable oil with a breeding cycle of two years; raw material acceptance includes verification of raw and auxiliary materials, sensory perception, quantity and qualification certificate of the supplier;

[0027] 2) Cleaning and soaking: Wash the glutinous rice and rice to remove impurities. After washing twice, add five times the weight of pure water to soak for 4 hours, stir for 10 minutes per hour, and the stirring speed is 100r / min; after soaking, take it out and dry it for later use; Put the washed mugwort leaves in the water and soak for 8 hours, take out the mugwort leaves and drain them for later use;

[0028] 3) Grinding: Grinding glutinous rice and rice into rice flour, passing through a 300-500 mesh sieve for later use;

[0029] 4...

Embodiment 2

[0037] see figure 1 , a kind of preparation method of green cake, comprises the following steps:

[0038] 1) Raw material acceptance: select glutinous rice, rice and mugwort leaves harvested in the current year; select pig fat and edible vegetable oil with a breeding cycle of two years; raw material acceptance includes verification of raw and auxiliary materials, sensory perception, quantity and qualification certificate of the supplier;

[0039] 2) Cleaning and soaking: Wash the glutinous rice and rice to remove impurities. After washing twice, add five times the weight of pure water to soak for 6 hours, stir for 10 minutes per hour, and the stirring speed is 100r / min; after soaking, take it out and dry it for later use; Put the washed mugwort leaves in the water and soak for 12 hours, take out the mugwort leaves and drain them for later use;

[0040] 3) Grinding: Grinding glutinous rice and rice into rice flour, passing through a 500-mesh sieve for subsequent use;

[0041]...

Embodiment 3

[0049] see figure 1 , a kind of preparation method of green cake, comprises the following steps:

[0050] 1) Raw material acceptance: select glutinous rice, rice and mugwort leaves harvested in the current year; select pig fat and edible vegetable oil with a breeding cycle of two years; raw material acceptance includes verification of raw and auxiliary materials, sensory perception, quantity and qualification certificate of the supplier;

[0051]2) Cleaning and soaking: Wash the glutinous rice and rice to remove impurities. After washing twice, add five times the weight of pure water to soak for 5 hours, stir for 10 minutes per hour, and the stirring speed is 100r / min; after soaking, take it out and dry it for later use; Put the washed mugwort leaves in the water and soak for 10 hours, take out the mugwort leaves and drain them for later use;

[0052] 3) Grinding: Grinding glutinous rice and rice into rice flour, passing through a 300-500 mesh sieve for later use;

[0053] 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com