Water-soluble fertilizer rich in amino acids and preparation method thereof

A water-soluble fertilizer and amino acid technology, applied in the direction of fertilizers made of biological waste, organic fertilizers, inorganic fertilizers, etc., can solve the problem of not being able to completely guarantee the effective and thorough killing of harmful bacteria and insect eggs, and the impossibility of flushing and foliar application Spraying can not completely eliminate fertilizer odor and other problems, and achieve the effect of improving and improving soil structure, improving quality and quality, and accelerating growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

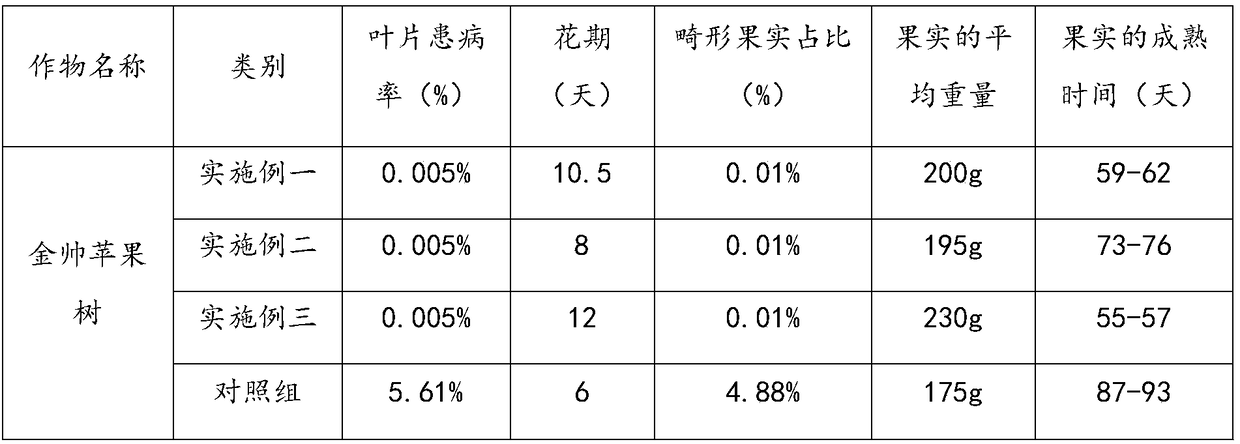

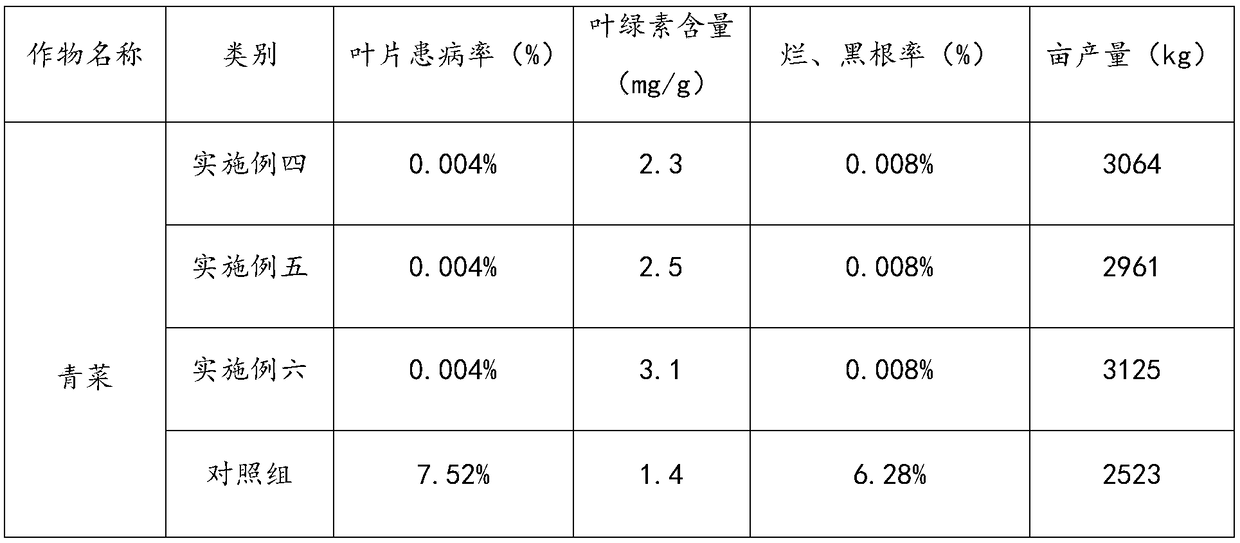

Examples

Embodiment 1

[0028] A water-soluble fertilizer rich in amino acids, prepared from the following raw materials in parts by weight: 65 parts of bagasse, 90 parts of beet bagasse, 40 parts of bean dregs, 20 parts of bone meal, 50 parts of plant ash, 8 parts of starter, 10 parts of compound amino acid powder, 3 parts of biocontrol bacteria, 0.5 parts of plant growth promoter.

[0029] The preparation method is as follows:

[0030] (1) Take bagasse, sugar beet bagasse, bean dregs, bone meal and plant ash according to the above ratio and grind them into powder, mix well and add 8-10 times of water, mix well and add 10-15 times of water, at 60-70 Celsius, let it stand for 2-3 hours, filter through a 20-30 mesh screen to obtain a mixed nutrient solution, and set aside;

[0031] (2) Add 10 parts of starter to the mixed nutrient solution with a weight ratio of saccharomycete and lactic acid bacteria of 2:2.1, and ferment in a sealed environment under aseptic conditions for 5-7 days, and filter thro...

Embodiment 2

[0037] A water-soluble fertilizer rich in amino acids, prepared from the following raw materials in parts by weight: 65 parts of bagasse, 90 parts of beet bagasse, 40 parts of bean dregs, 20 parts of bone meal, 50 parts of plant ash, 8 parts of starter, 10 parts of compound amino acid powder, 3 copies of bio-control bacteria.

[0038] The preparation method is as follows:

[0039] (1) Take bagasse, sugar beet bagasse, bean dregs, bone meal and plant ash according to the above ratio and grind them into powder, mix well and add 8-10 times of water, mix well and add 10-15 times of water, at 60-70 Celsius, let it stand for 2-3 hours, filter through a 20-30 mesh screen to obtain a mixed nutrient solution, and set aside;

[0040] (2) Add 10 parts of a starter consisting of yeast and lactic acid bacteria at a weight ratio of 2:2.1 to the mixed nutrient solution, and ferment in a sealed container under aseptic conditions for 5-7 days, filter through a 100-120 mesh screen, and concent...

Embodiment 3

[0046] A water-soluble fertilizer rich in amino acids, prepared from the following raw materials in parts by weight: 80 parts of bagasse, 100 parts of beet bagasse, 50 parts of bean dregs, 30 parts of bone meal, 60 parts of plant ash, 10 parts of starter, 15 parts of compound amino acid powder, 5 parts of biocontrol bacteria, 0.8 parts of plant growth promoter.

[0047] The components of the water-soluble fertilizer in this example are exactly the same as in Example 1, the difference is that the weight ratio of each component is different, and the preparation method is exactly the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com