N-alkane isomerization catalyst and preparation method thereof

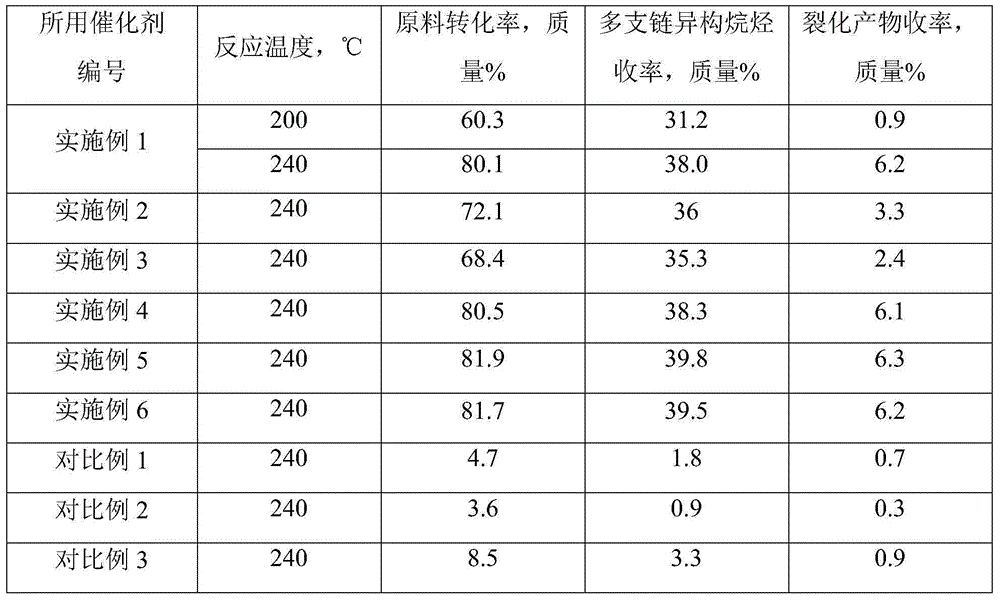

A technology of n-alkane and catalyst, which is applied in the field of n-alkane isomerization catalyst and its preparation, can solve the problems of selectivity and catalytic activity that cannot meet the requirements of n-alkane isomerization, and achieve high catalytic activity and multi-branched The effect of isomerization selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

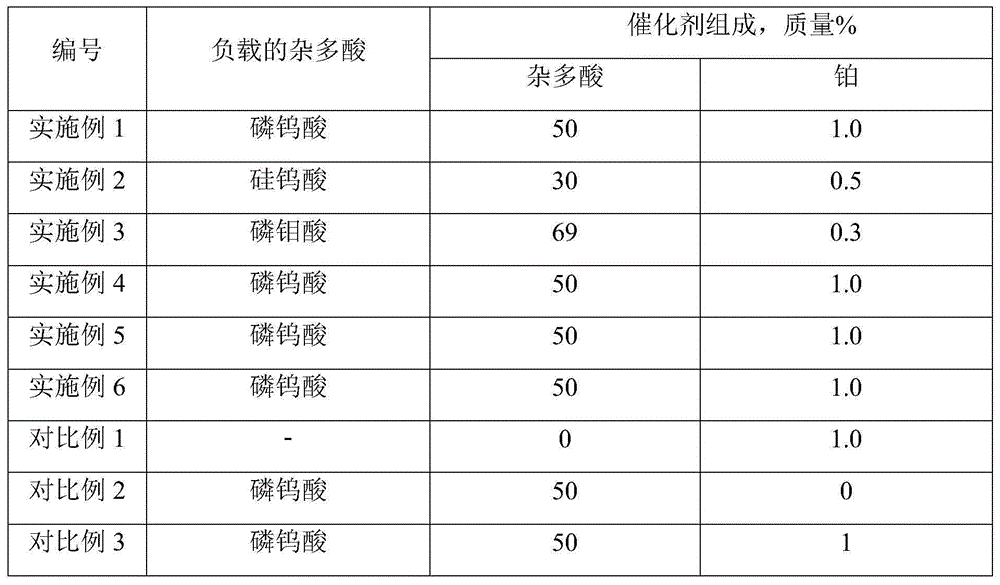

[0014] The present invention provides a kind of preparation method of n-alkane isomerization catalyst, this method comprises: (1) active metal component platinum is supported on the alumina carrier, obtains the first intermediate after drying; (2) step (1) performing a reduction treatment on the obtained first intermediate to obtain a second intermediate; (3) loading the heteropolyacid on the second intermediate obtained in step (2) and drying to obtain a catalyst.

[0015] In the method of the present invention, the impregnation method can be used to support the metal platinum component on the alumina. The impregnation method can be a saturated impregnation method or a supersaturated impregnation method. The saturated impregnation method is preferred in the present invention. For example, with respect to 100 parts by weight of an alumina carrier, 70-150 mL of platinum containing 0.14-20 mg / mL can be used. The aqueous solution of the platinum compound impregnates the alumina s...

Embodiment 1

[0030] 10g γ-Al 2 o 3Put it into a rotary evaporator, add 15 mL of chloroplatinic acid solution with a platinum content of 6.67 mg / mL, soak at 60° C. for 4 hours, and then evaporate to dryness to obtain the first intermediate.

[0031] The above-mentioned first intermediate is loaded into the reactor, and the reduction treatment is carried out to obtain the second intermediate, wherein the conditions of the reduction treatment include: the hydrogen volume space velocity is 1200 hours -1 , the reduction temperature is 480°C, and the reduction time is 4 hours.

[0032] Then use 15mL of 0.33g / mL aqueous solution of phosphotungstic acid to impregnate the above-mentioned second intermediate at 60°C for 2 hours, and then rotate to dryness to obtain the catalyst, whose composition is shown in Table 1.

Embodiment 2

[0034] 10gη-Al 2 o 3 Put it into a rotary evaporator, add 8 mL of chloroplatinic acid solution with a platinum content of 5.63 mg / mL, soak at 60° C. for 4 hours, and dry by rotary evaporation to obtain the first intermediate.

[0035] The above-mentioned first intermediate is loaded into the reactor, and the reduction treatment is carried out to obtain the second intermediate, wherein the conditions of the reduction treatment include: the hydrogen volume space velocity is 30 hours -1 , the reduction temperature was 200° C., and the reduction time was 8 hours to obtain the second intermediate.

[0036] Then, 8 mL of 0.38 g / mL silicotungstic acid aqueous solution was used to impregnate the above-mentioned second intermediate at 60°C for 2 hours, and then evaporated to dryness to obtain the catalyst, whose composition is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com