Mineralization preparation device of urban and rural drinking water and drinking water mineralization method

A technology for preparing equipment and drinking water, applied in chemical instruments and methods, water/sewage treatment, water/sewage treatment equipment, etc., can solve problems such as inability to achieve mineralized water, lagging water supply and treatment technology, unfavorable township development, etc., to achieve Achieve safety and health, reduce the cost of drinking water for residents, and achieve high feasibility of water supply scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

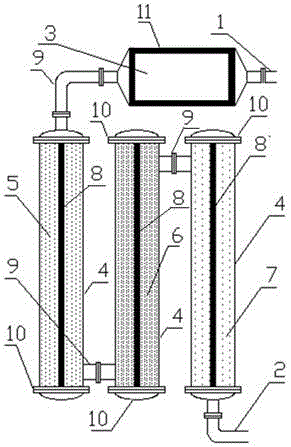

[0045] Such as figure 1As shown, the urban and rural drinking water mineralization preparation device of the present invention, wherein, the water inlet pipe 1, the water outlet pipe 2, the activation tank 3, the functional tank body 4, the sterilization and disinfection filler 5, the adsorption filter filler 6, the mineralization filler 7, the magnetization column 8. Connecting pipe between tanks 9, detachable head 10, magnetized material 11.

[0046] An urban and rural drinking water mineralization preparation device, comprising an activation tank 3, one end of the activation tank 3 is connected to a water inlet pipe 1, and the other end is connected to a functional tank body 4 through an inter-tank connecting pipe 9, and the functional tank body 4 The other end is connected to the outlet pipe 2;

[0047] Among them, there are 3 functional tanks 4, including 1 functional tank filled with sterilizing filler 5, 1 functional tank filled with adsorption filter filler 6, and 1 f...

Embodiment 2

[0062] An urban and rural drinking water mineralization preparation device, comprising an activation tank 3, one end of the activation tank 3 is connected to a water inlet pipe 1, and the other end is connected to a functional tank body 4 through an inter-tank connecting pipe 9, and the functional tank body 4 The other end is connected to the outlet pipe 2;

[0063] Among them, there are 5 functional tanks 4, including 2 functional tanks filled with sterilization and disinfection filler 5, 2 functional tanks filled with adsorption filter filler 6, and 1 functional tank filled with mineralization filler 7;

[0064] The activation tank 3, the functional tank filled with the sterilizing filler 5, the functional tank filled with the adsorption filter filler 6 and the functional tank filled with the mineralized filler 7 are connected in series through connecting pipes between tanks;

[0065] A magnetized column 8 is also arranged in the functional tank body 4;

[0066] A magnetize...

Embodiment 3

[0078] An urban and rural drinking water mineralization preparation device, comprising an activation tank 3, one end of the activation tank 3 is connected to a water inlet pipe 1, and the other end is connected to a functional tank body 4 through an inter-tank connecting pipe 9, and the functional tank body 4 The other end is connected to the outlet pipe 2;

[0079] Among them, there are 6 functional tanks 4, including 1 functional tank filled with sterilizing filler 5, 3 functional tanks filled with adsorption filter filler 6, and 2 functional tanks filled with mineralized filler 7;

[0080] The activation tank 3, the functional tank filled with the sterilizing filler 5, the functional tank filled with the adsorption filter filler 6 and the functional tank filled with the mineralized filler 7 are connected in series through connecting pipes between tanks;

[0081] A magnetized column 8 is also arranged in the functional tank body 4;

[0082] A magnetized material 11 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com