Anti-dazzle display glass and manufacture technology thereof and anti-dazzle display glass spray machine

An anti-glare, spraying machine technology, applied in the direction of coating, can solve the problems of increased product defect rate, appearance defects, easy to fall off, etc., to improve the viewing angle and brightness, reduce debris and scratches, and increase the spraying area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

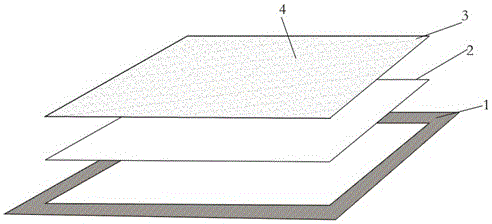

[0040] refer to Figure 1 to Figure 4 , the present invention discloses an anti-glare display glass, comprising

[0041] As the base glass substrate 2, an ink surface 1 is provided below the glass substrate 2, and a spray surface 3 is provided on its upper end, and a nano-scale silicon dioxide particle film layer 4 is spray-coated on the spray surface 3. The silicon particle film layer 4 is composed of numerous nanometer silicon dioxide particles piled up into an uneven shape; after heating, it forms an adhesion force with the glass surface,

[0042] The thickness of the glass substrate 2 is 3-8mm,

[0043] The thickness of the ink surface 1 is 8-12um.

[0044] The manufacturing proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com