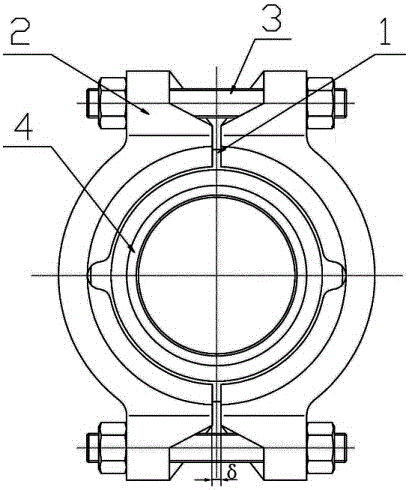

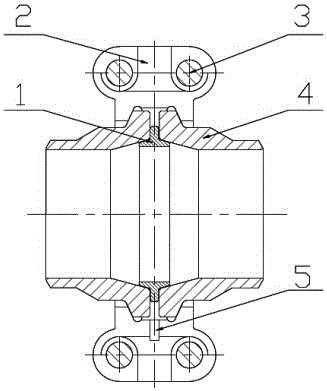

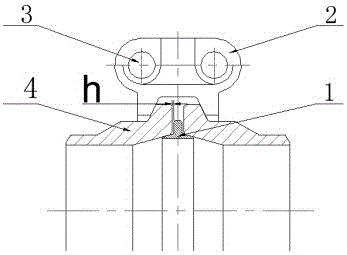

High-pressure self-tightening flange

A self-tightening, flanged technology, used in flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of long maintenance time, affecting sealing performance, insufficient strength, etc., to achieve convenient processing and maintenance, Long service life and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Traditional pipeline connection usually adopts flange connection. Due to the requirement of sealing structure, the flange connection is often large in size and difficult to install. The present invention combines the double-cone seal structure and the clamp fastening structure, utilizes the characteristics of the ferrule in the present invention in terms of structural fastening, and the characteristics of the double-cone seal in the axial seal, after scientific analysis, and adopts a large-scale limited The meta-analysis software has carried out the mechanical calculation work, and carried out the strength analysis and verification of the high-pressure self-tightening flange ZY-LOC described in the present invention. The application environment of this high-pressure self-tightening flange: pressure ≤ 200MPa, temperature: -196°C~1000°C.

[0031] In addition, because the application prospect of the flange is very wide, according to the actual technical requirements of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com