Low absorption-radiation ratio thermal control coating on titanium alloy surface and preparation method thereof

A technology of titanium alloy and coating, which is applied in the field of spacecraft thermal control coating, can solve the problems of thermal control of titanium alloy parts, and achieve the effect of high bonding strength and good resistance to vacuum-external radiation

Inactive Publication Date: 2011-06-22

SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to propose a low absorption-radiation ratio thermal control coating on the surface of titanium alloy and its preparation method in order to solve the above-mentioned problems, so as to solve the problem of thermal control of titanium alloy parts for external use in spacecraft

The low-absorption-radiation ratio thermal control coating on the surface of titanium alloy of the present invention is prepared by plasma electrolytic oxidation method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Login to View More

Abstract

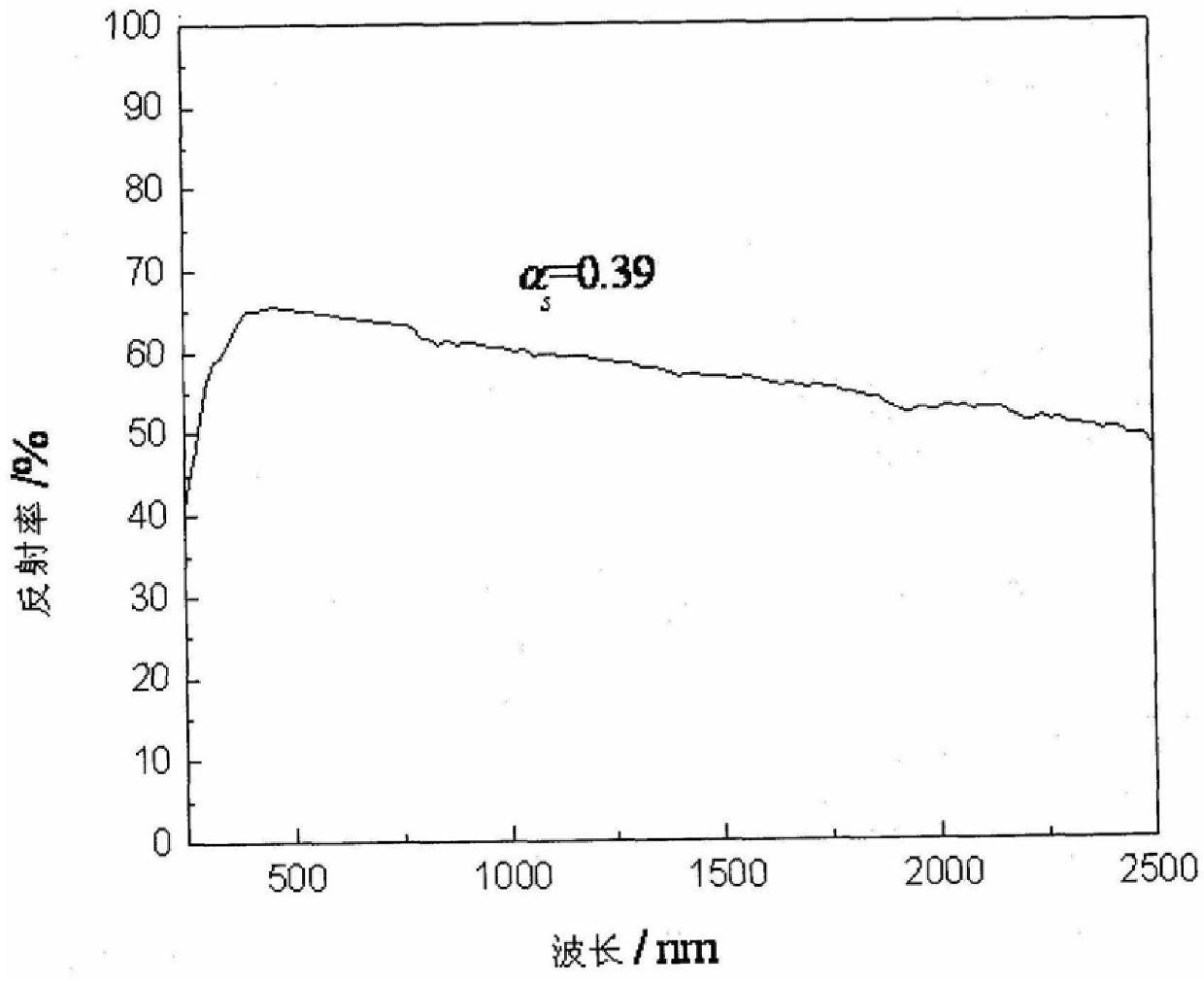

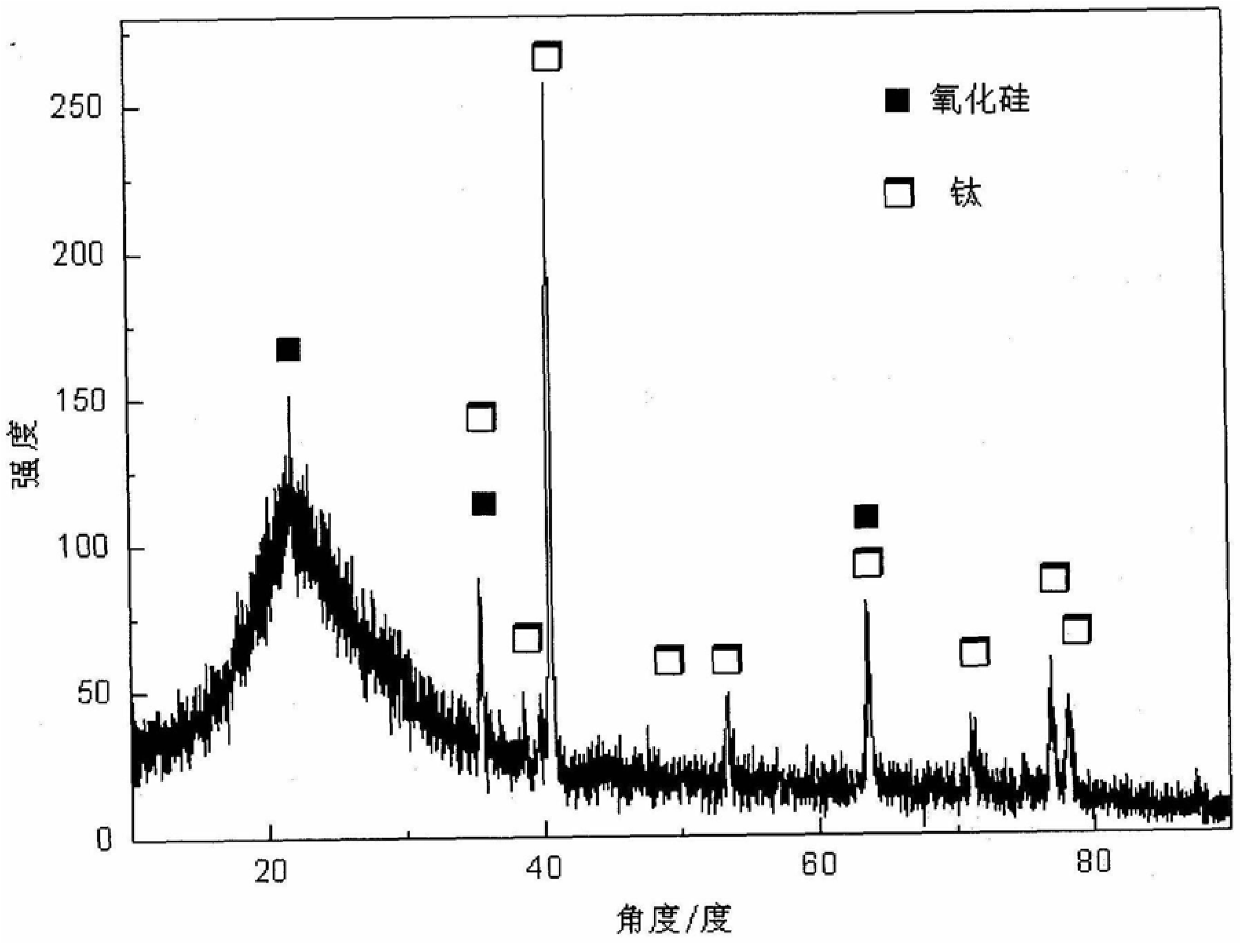

The invention relates to a thermal control coating with a low absorption-radiation ratio on the surface of a titanium alloy and a preparation method thereof, belonging to the technical field of thermal control coatings for spacecraft. The invention utilizes plasma electrolytic oxidation method to prepare, adopts sodium hypophosphite or potassium hypophosphite 5-20g / l, potassium water glass or sodium water glass 40-100g / l as electrolytic solution, adopts AC pulse power supply to control the titanium alloy In the oxidation process, the prepared coating is composed of silicon dioxide, which is composed of α-cristobalite and amorphous silicon oxide, and the two phases are mixed and distributed in the coating. The titanium alloy surface of the present invention has a low radiation absorption ratio heat control solar absorption ratio (in the solar radiation interval of 250-2500nm) is lower than 0.45, the hemispherical infrared radiation rate is greater than 0.8, and the ratio of the solar absorption ratio to the hemispherical infrared radiation rate is less than 0.5 , can adapt to the processing of the surface of parts with more complex structures, has high bonding strength with the substrate, and the coating has good space stability, which solves the problem of temperature control of spacecraft exposed to extraterrestrial titanium alloy parts.

Description

Low absorption-radiation ratio thermal control coating on titanium alloy surface and preparation method thereof technical field The invention relates to a thermal control coating with a low absorption-radiation ratio on the surface of a titanium alloy and a preparation method thereof, in particular to a coating and a preparation method for the thermal control of titanium alloy parts externally used in spacecraft, and belongs to the thermal control coating technology of spacecraft field. Background technique With the development of China's space technology, the functional requirements of space vehicles are becoming wider and wider, and the shapes of extraterrestrial equipment are becoming more and more complex. my country's spacecraft have increasingly strong demand for large-scale structures and mechanisms such as antennas. Large-scale structures and mechanisms will be used more and more in my country's future spacecraft. The temperature control of various moving parts of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C25D11/26C25D11/02

Inventor 辛世刚赵荣根都徽宋力昕

Owner SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com