Food solidification powder applicable to people suffering from dysphagia and preparation method of food solidification powder applicable to people suffering from dysphagia

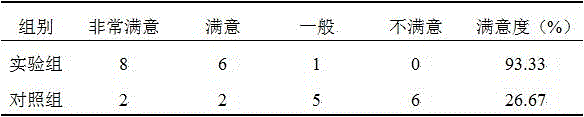

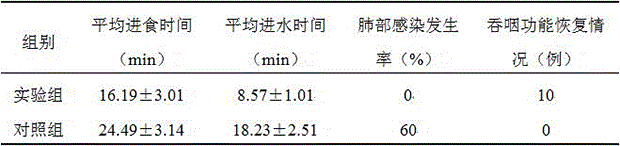

A technology for swallowing disorders and food, applied in the field of food coagulation powder and its production, can solve the problems affecting the use range and convenience of products, affecting industrial development, poor taste, etc., to reduce the risk of aspiration, recovery of swallowing function, and taste. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

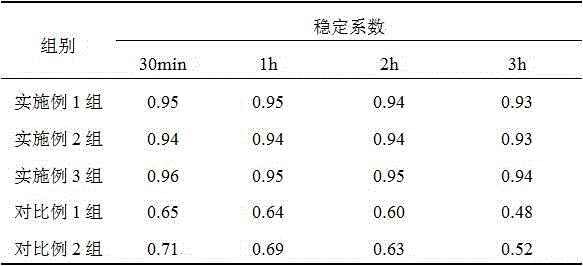

Examples

Embodiment 1

[0029] A food coagulation powder suitable for people with dysphagia, the food coagulation powder includes the following raw materials: 16 parts of rice, 8 parts of corn, 1 part of xanthan gum, 3 parts of gum arabic, 1 part of microcrystalline cellulose, malt paste Refined 62 parts.

[0030] It is prepared by the following method:

[0031] S1: Mix the rice and corn according to the above ratio and crush them to pass through a 60-mesh sieve, puff them with a twin-screw extruder, and then crush them to 60 meshes to obtain puffed powder; puffing parameters: the temperature in the first zone is 60°C, and the temperature in the second zone is 100°C , the temperature in the third zone is 120°C;

[0032] S2: Mix the puffed powder, gum arabic and part of the maltodextrin prepared in step S1 evenly, add water to dissolve and then spray dry to obtain the standby powder; spray drying conditions: air inlet temperature 130°C, air outlet temperature 90°C; malt The consumption of dextrin ac...

Embodiment 2

[0038] A food coagulation powder suitable for people with dysphagia, the food coagulation powder includes the following raw materials: 20 parts of rice, 10 parts of corn, 2 parts of xanthan gum, 4 parts of gum arabic, 2 parts of microcrystalline cellulose, malt paste Refined 70 parts.

[0039] It is prepared by the following method:

[0040] S1: Mix rice and corn according to the above ratio, crush them to pass through a 60-mesh sieve, puff them with a twin-screw extruder, and then crush them to 60 meshes to obtain puffed powder; puffing parameters: the temperature in the first zone is 70°C, and the temperature in the second zone is 110°C , the temperature in the third zone is 130°C;

[0041] S2: Mix the puffed powder, gum arabic and part of the maltodextrin prepared in step S1 evenly, add water to dissolve and then spray dry to obtain the standby powder; spray drying conditions: air inlet temperature 150°C, air outlet temperature 100°C; malt The consumption of dextrin accou...

Embodiment 3

[0047] This example is similar to Example 1, except that 18 parts of rice, 9 parts of corn, 1.5 parts of xanthan gum, 3.5 parts of gum arabic, 1.5 parts of microcrystalline cellulose, and 66.5 parts of maltodextrin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com