A portable usb electric heating insulation cup

A thermos cup, portable technology, applied to heating devices, other household utensils, clay products, etc., can solve the problems of inconvenient charging, limited use space, inconvenient to carry, etc., to shorten the heating time and prevent overheating Unevenness, the effect of reducing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

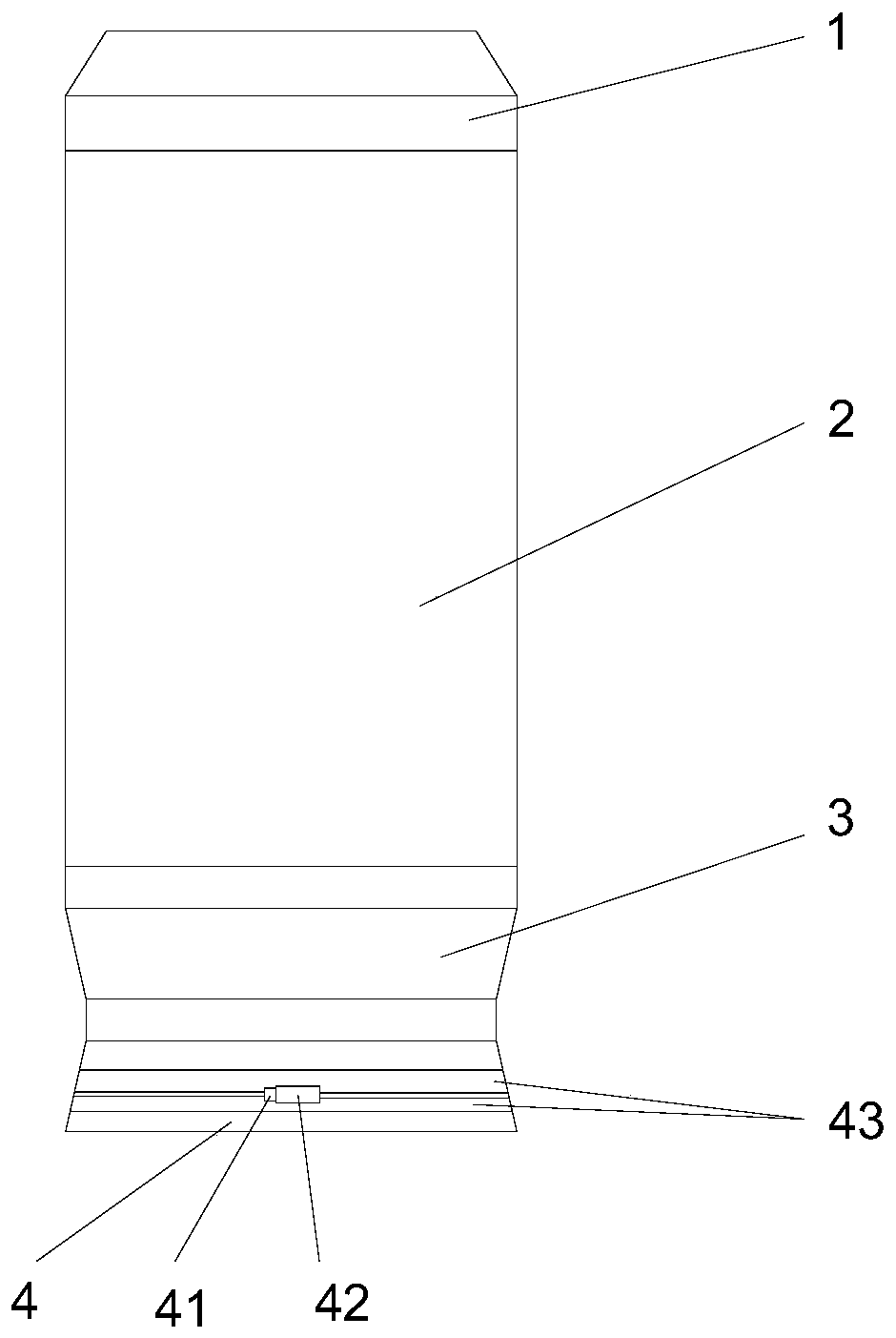

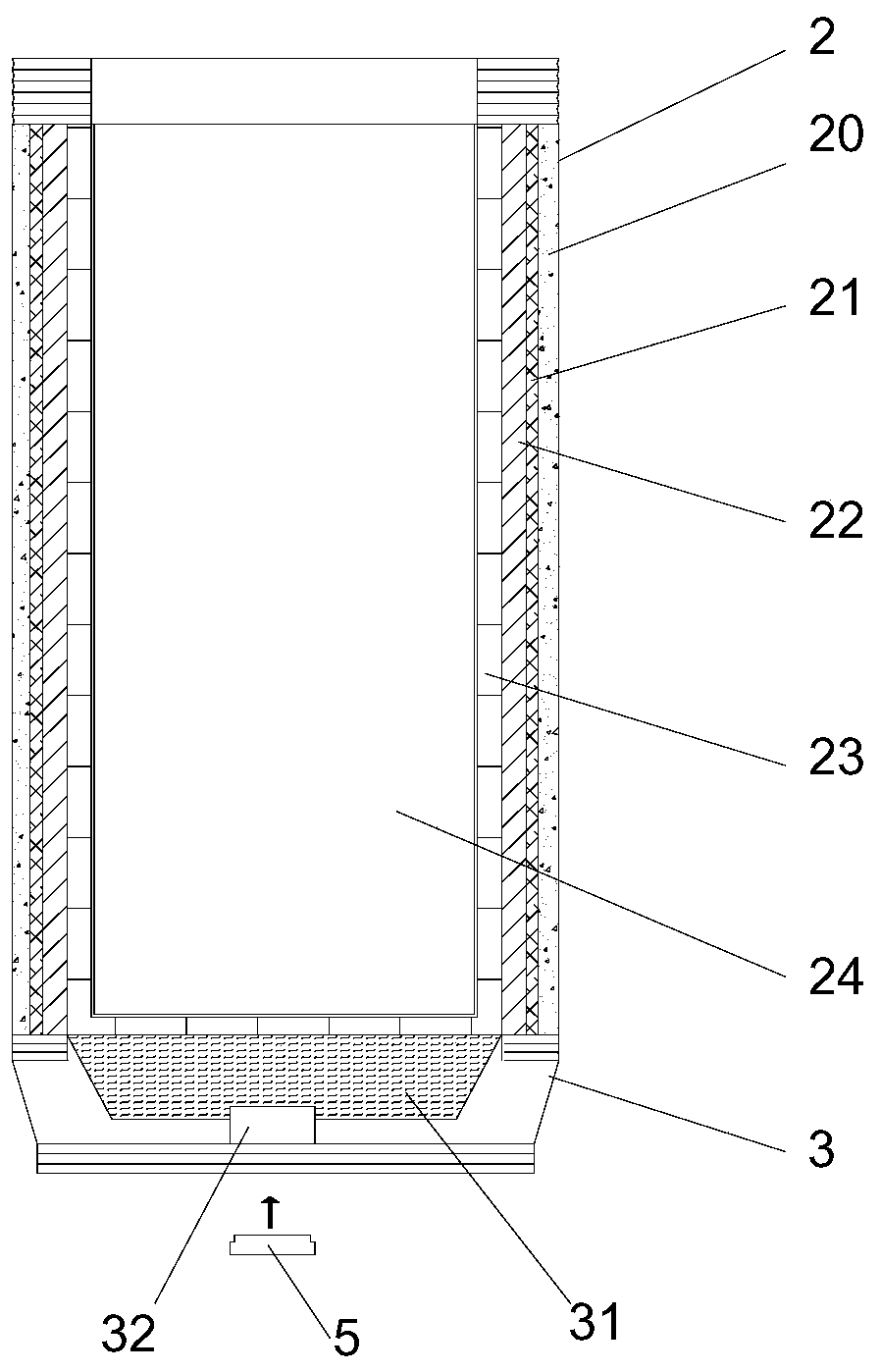

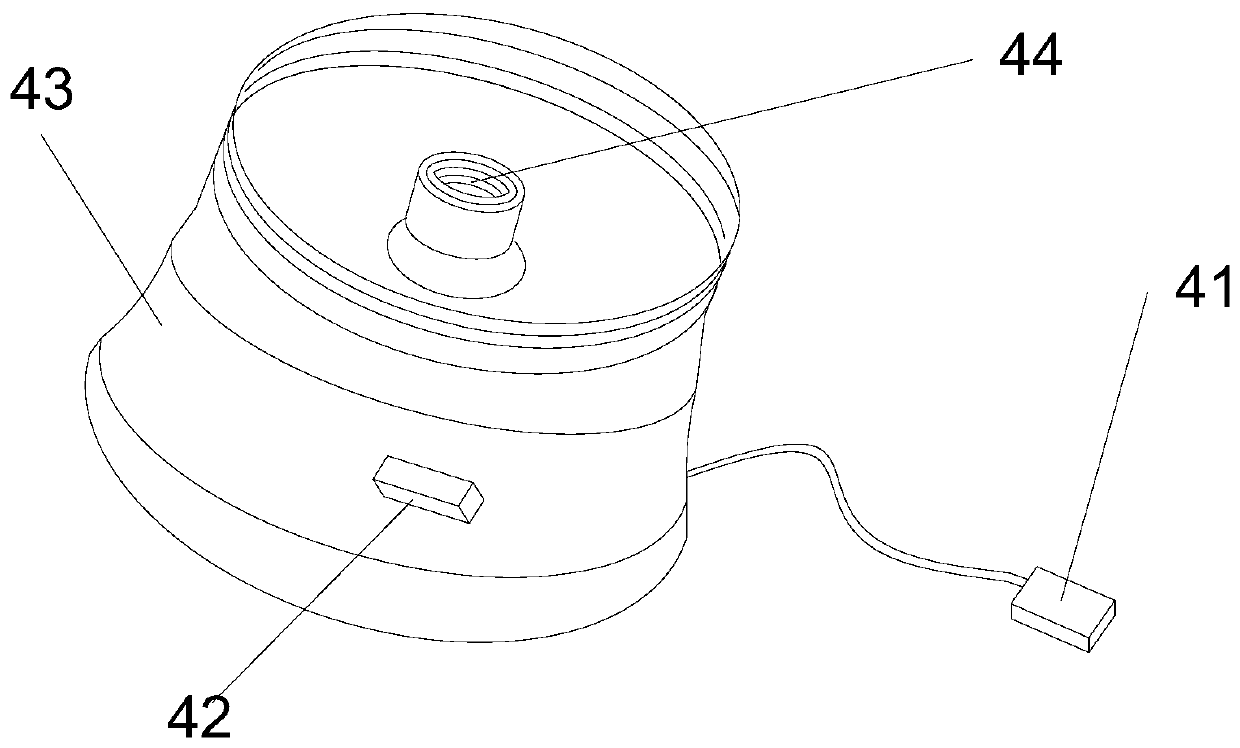

[0033] Such as Figure 1-4As shown, a portable USB electric thermos cup, the thermos cup has a specification capacity of 500mL; it includes a cup base, a cup body 2 and a cup cover 1, and the cup body 2 is composed of a waterproof shell 20, a heat insulation layer 21, Insulation layer 22, a heating layer 23 made of steel and a cylinder with an upper end opening made of stainless steel inner tank 24; the upper opening of the cup cover 1 and the cup body 2 are connected by threads; the cup base includes a first cup base 3 and the second cup base 4, one end of the first cup base 3 is threaded to the cup body 2, the other end of the first cup base 3 is threaded to the second cup base 4, and the first cup base 3 is provided with a heating assembly 31 and the first conductive connection port 32 electrically coupled with the heating assembly 31, the port of the first conductive connection port 32 is located at the bottom end of the first cup base 3, the heating assembly 31 is in clos...

Embodiment 2

[0044] The working principle is the same as that of Example 1, the difference is:

[0045] 1. The cup body 2 of the thermos cup is also provided with a cartoon pattern, which makes the appearance more beautiful.

[0046] 2. The heating plate is made of the following raw materials: 5 parts by weight of clay, 5 parts of talcum powder, 5 parts of fused magnesia, 5 parts of carbon fiber, 5 parts of silicon dioxide, 5 parts of lanthanum chromate, After mixing 5 parts of molybdenum dioxide, it is calcined and melted at a high temperature of 2200°C to obtain a melt, and then cooled to 500°C and poured into a heating plate mold for molding, and then quickly lowered to room temperature in a nitrogen environment for shaping, and then heat can be obtained plate.

[0047] 3. The waterproof case 20 is made of a mixed metal material, and the mixed metal material is composed of 3 parts by weight of copper, 3 parts by weight of zinc, 3 parts by weight of nickel, and 3 parts by weight of iron...

Embodiment 3

[0055] The working principle is the same as that of Example 1, the difference is:

[0056] 1. The heating plate is made of the following raw materials: 4 parts by weight of clay, 3 parts of talcum powder, 4 parts of fused magnesia, 3 parts of carbon fiber, 2 parts of silicon dioxide, 3 parts of lanthanum chromate, After 2 parts of molybdenum dioxide are mixed, they are calcined and melted at a high temperature of 2000°C to obtain a melt, and then cooled to 450°C and poured into a heating plate mold to shape, and then quickly lowered to room temperature in a nitrogen environment to set the shape, and then heat can be obtained. plate.

[0057] 2. The waterproof case 20 is made of a mixed metal material, and the mixed metal material is composed of 2 parts by weight of copper, 2 parts by weight of zinc, 2 parts by weight of nickel, and 2 parts by weight of iron. The waterproof case 20 made by mixing these four materials not only improves the anti-crack ability, but also has high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com