Konjac glucomannan shower gel and preparation method thereof

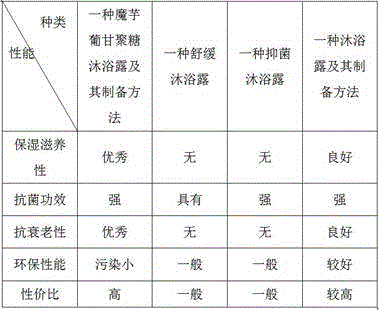

A technology of konjac glucomannan and shower gel, which is applied in the directions of pharmaceutical formulations, cosmetic preparations, and cosmetic preparations, etc., can solve problems such as being incompatible with the needs of the times, and achieve strong cleaning ability, skin whitening, and skin promotion. effects of metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, a kind of preparation method of konjac glucomannan shower gel is characterized in that the operation steps are as follows:

[0024] (1) Preparation of purified konjac glucomannan powder: In parts by mass, add 12 g of konjac fine powder to 4000 g of deionized water at 80 °C while stirring, stir at a speed of 400 r / min for 35 min, then let stand for 2 h, and then Remove insoluble impurities by suction filtration, retain the filtrate; concentrate the filtrate to a water content of 35% by rotary evaporation, use ethanol with a volume ratio of 95% as a precipitant, pour it into the concentrated filtrate, stir while pouring, collect the precipitate and use Wash with absolute ethanol, then dry the precipitate in a blast drying oven at 35°C for 5 hours, and then dry it in a vacuum drying oven at 30°C until the quality remains constant to obtain purified konjac glucomannan powder, which is ready for use;

[0025] (2) Preparation of konjac glucomannan sol solution: ...

Embodiment 2

[0032] Embodiment 2, a kind of preparation method of konjac glucomannan shower gel, comprises the following steps:

[0033](1) Preparation of purified konjac glucomannan powder: in parts by mass, add 10 g of konjac fine powder to 3000 g of deionized water at 70 °C while stirring, stir at a speed of 400 r / min for 35 min, then let stand for 2 h, pump Remove insoluble impurities by filtration, retain the filtrate; concentrate the filtrate to a water content of 35% by rotary evaporation, use ethanol with a volume ratio of 95% as a precipitant, pour it into the concentrated filtrate, stir while pouring, collect the precipitate and use Wash with water and ethanol, then dry the precipitate in a blast drying oven at 35°C for 6 hours, and then dry it in a vacuum drying oven at 35°C until the quality remains constant to obtain purified konjac glucomannan powder, which is ready for use;

[0034] (2) Preparation of konjac glucomannan sol solution: Take 8g of sucrose fatty acid ester and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com