Preparation method of magnetic nanoparticle modified activated sludge adsorbing agent

A technology of activated sludge adsorption and magnetic nanometer, applied in the field of adsorption, can solve the problems of low sludge sedimentation and separation capacity, easy sludge bulking, small processing capacity, etc., and achieves easy magnetic separation, improved resource utilization, and convenient recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

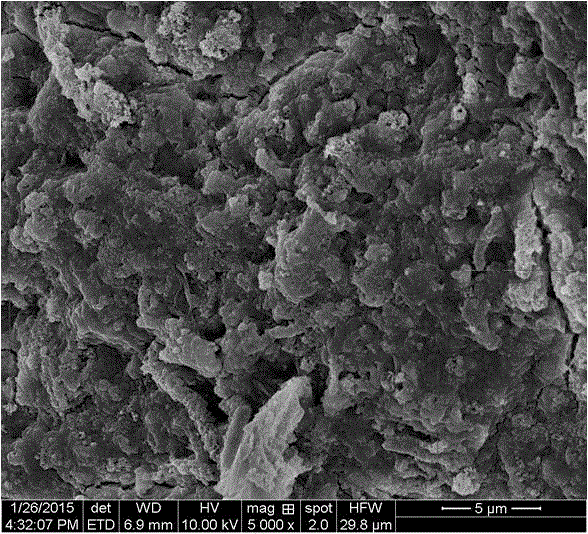

[0017] Embodiment 1 A kind of preparation method of magnetic nanomaterial modified activated sludge adsorbent

[0018] (1) Dry the activated sludge from the sewage treatment plant at 102°C, grind, and sieve with 80 meshes to obtain dry sludge;

[0019] (2) Dissolve 7 g of dry sludge powder in 70 mL of distilled water and heat in a water bath at 60 °C;

[0020] (3) 2.5 g FeCl 3 Dissolve in 180 mL of distilled water and heat in a water bath at 60°C to obtain FeCl 3 solution;

[0021] (4) 3 g FeSO 4 Dissolve in 22 mL of distilled water and heat in a water bath at 60°C to obtain FeSO 4 solution;

[0022] (5) FeCl 3 solution and FeSO 4 After the solution was mixed and stirred, it was poured into the stirred sludge. The three solutions were mixed and stirred in a water bath at 60°C for 25 minutes. The pH was adjusted to 10 with NaOH, and then stirred for 50 minutes. Washing and drying to obtain magnetic activated sludge.

Embodiment 2

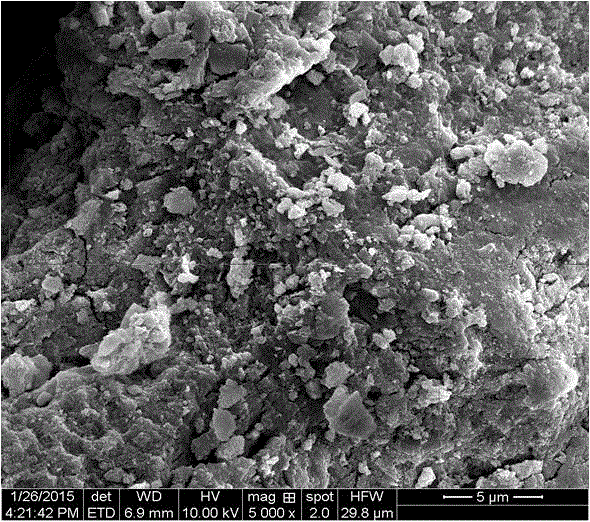

[0023] Example 2 A preparation method of magnetic nanomaterial modified activated sludge adsorbent

[0024] (1) Dry the activated sludge from the sewage treatment plant at 105°C, grind, and sieve with 100 mesh to obtain dry sludge;

[0025] (2) Dissolve 9 g of dry sludge powder in 90 mL of distilled water and heat in a water bath at 70 °C;

[0026] (3) 3 g FeCl 3 Dissolve in 216 mL of distilled water and heat in a water bath at 70°C to obtain FeCl 3 solution;

[0027] (4) 3.6 g FeSO 4 Dissolve in 27 mL of distilled water and heat in a water bath at 70°C to obtain FeSO 4 solution;

[0028] (5) FeCl 3 solution and FeSO 4 After the solution was mixed and stirred, it was poured into the stirred sludge. The three solutions were mixed and stirred in a water bath at 70°C for 30 minutes. The pH was adjusted to 10 with NaOH, and then stirred for 60 minutes. Washing and drying to obtain magnetic activated sludge.

Embodiment 3

[0029] Embodiment 3 A kind of preparation method of magnetic nanomaterial modified activated sludge adsorbent

[0030] (1) Dry the activated sludge from the sewage treatment plant at 110°C, grind, and sieve with 150 mesh to obtain dry sludge;

[0031] (2) Dissolve 10 g of dry sludge powder in 100 mL of distilled water and heat in a water bath at 80 °C;

[0032] (3) 3.6 g FeCl 3 Dissolve in 260 mL of distilled water and heat in a water bath at 80°C to obtain FeCl 3 solution;

[0033] (4) 4 g FeSO 4 Dissolve in 30 mL of distilled water and heat in a water bath at 80°C to obtain FeSO 4 solution;

[0034] (5) FeCl 3 solution and FeSO 4 After the solution was mixed and stirred, it was poured into the stirred sludge. The three solutions were mixed and stirred in a water bath at 80°C for 45 minutes. The pH was adjusted to 10 with NaOH, and then stirred for 70 minutes. Washing and drying to obtain magnetic activated sludge.

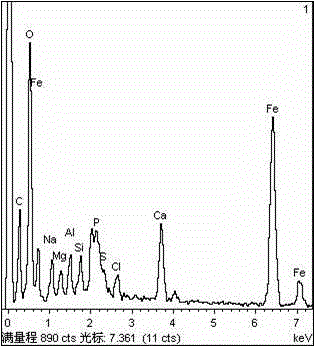

[0035] Example 4 The weight percentage of Fe in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com