Automotive stretch-resistant setting-type flat carpet

A kind of anti-stretching, leveling technology, applied in vehicle parts, special positions of vehicles, lamination and other directions, can solve the problems of reducing elongation, affecting product quality, high product hardness, etc., to prevent the breeding of bacteria, good anti-slip effect , Increase the effect of anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

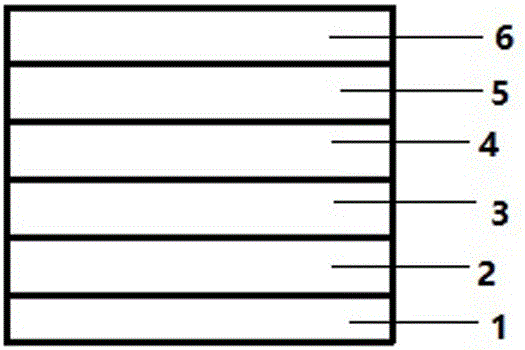

[0042] An automobile anti-stretch shaped flat carpet, comprising a PET carpet fabric layer (3), the PET carpet fabric layer (3) comprising a weight ratio of 90% of ordinary PET fibers and 10% of low melting point PET fibers, the PET The thickness of the carpet fabric layer (3) is 0.65 mm; the front of the PET carpet fabric layer (3) is provided with an anti-corrosion layer (4), the thickness of the anti-corrosion layer (4) is 0.16 mm, and the anti-corrosion layer (4 ) is an epoxy resin layer; the back of the PET carpet fabric layer (3) is provided with an expansion buffer layer (2), the thickness of the expansion buffer layer (2) is 0.25 mm, and the expansion buffer layer (2) includes The following weight ratio raw materials:

[0043] Polyurethane: 45 parts, PET: 26 parts, carbon nanofiber: 3 parts, bentonite: 1.6 parts, white oil: 1.5 parts, citric acid: 0.8 parts, vinyltrimethoxysilane: 0.6 parts, dioctyl sebacate: 2.5 parts, impact modifier: 1.54 parts.

[0044] Further, ...

Embodiment 2

[0065] An automobile anti-stretch shaped flat carpet, comprising a PET carpet fabric layer (3), the PET carpet fabric layer (3) comprising a weight ratio of 90% of ordinary PET fibers and 10% of low melting point PET fibers, the PET The thickness of the carpet fabric layer (3) is 0.5 mm; the front side of the PET carpet fabric layer (3) is provided with an anti-corrosion layer (4), the thickness of the anti-corrosion layer (4) is 0.1 mm, and the anti-corrosion layer (4 ) is an epoxy resin layer; the back of the PET carpet fabric layer (3) is provided with an expansion buffer layer (2), the thickness of the expansion buffer layer (2) is 0.3 mm, and the expansion buffer layer (2) includes The following weight ratio raw materials:

[0066] Polyurethane: 42 parts, PET: 28 parts, carbon nanofiber: 2 parts, bentonite: 1 part, white oil: 2 parts, citric acid: 0.5 parts, vinyltrimethoxysilane: 0.8 parts, dioctyl sebacate: 3 parts, impact modifier: 2 parts.

[0067] Further, the impa...

Embodiment 3

[0088] An automobile anti-stretch shaped flat carpet, comprising a PET carpet fabric layer (3), the PET carpet fabric layer (3) comprising a weight ratio of 90% of ordinary PET fibers and 10% of low melting point PET fibers, the PET The thickness of the carpet fabric layer (3) is 0.8 mm; the front of the PET carpet fabric layer (3) is provided with an anti-corrosion layer (4), the thickness of the anti-corrosion layer (4) is 0.2 mm, and the anti-corrosion layer (4 ) is an epoxy resin layer; the back of the PET carpet fabric layer (3) is provided with an expansion buffer layer (2), the thickness of the expansion buffer layer (2) is 0.2 mm, and the expansion buffer layer (2) includes The following weight ratio raw materials:

[0089] Polyurethane: 50 parts, PET: 20 parts, carbon nanofiber: 4 parts, bentonite: 2 parts, white oil: 1 part, citric acid: 1 part, vinyltrimethoxysilane: 0.4 parts, dioctyl sebacate: 2 parts, impact modifier: 1 part.

[0090] Further, the impact modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com