Gas Injection and Shallow Super Heavy Oil Production Integrated Device

A super-heavy oil, shallow-layer technology, applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of frequent turnover, large operation and construction volume, and high cost of steam injection, and avoid relaxation The effect of partial wear, reducing the cost of steam injection and prolonging the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

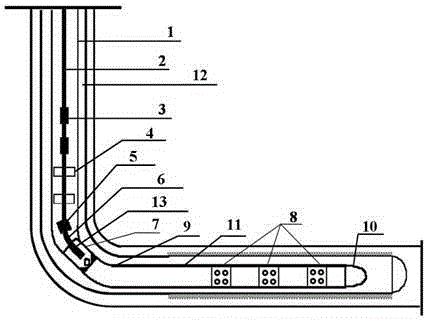

[0024] figure 1 It is a structural diagram of a specific embodiment of the thin and shallow ultra-heavy oil injection-production integrated device of the present invention. The thin and shallow ultra-heavy oil injection-production integrated device includes a tubing string and a sucker rod string. In the tubing string, there is a nitrogen heat insulation layer 12 between the outer wall of the tubing and the inner wall of the casing. The tubing string is from top to bottom. The following are: oil pipe 1 with an outer diameter of 89 mm, a high-slope injection-production integrated pump 7, a variable diameter joint 9, a chamfered oil pipe with an outer diameter of 73 mm 11, a multi-point uniform injector 8, and a shoe plug 10; The oil rod string includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com