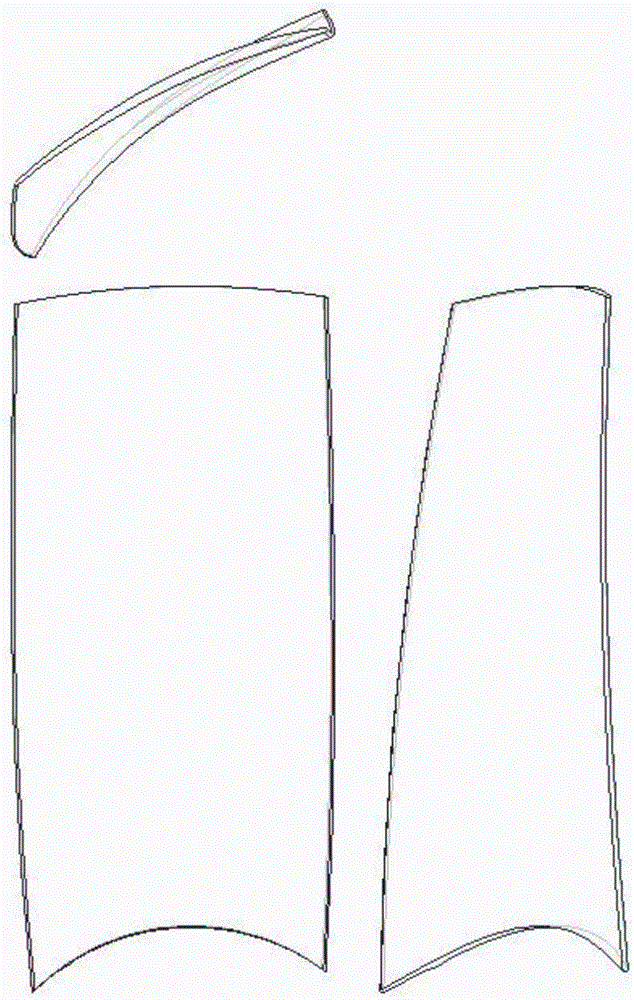

Axial-flow swept blade

A sweeping blade technology, applied in the field of fan impeller components, can solve the problems of high noise, low efficiency of axial flow fan, inconsistent vortex at the trailing edge of the blade, etc., and achieve good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

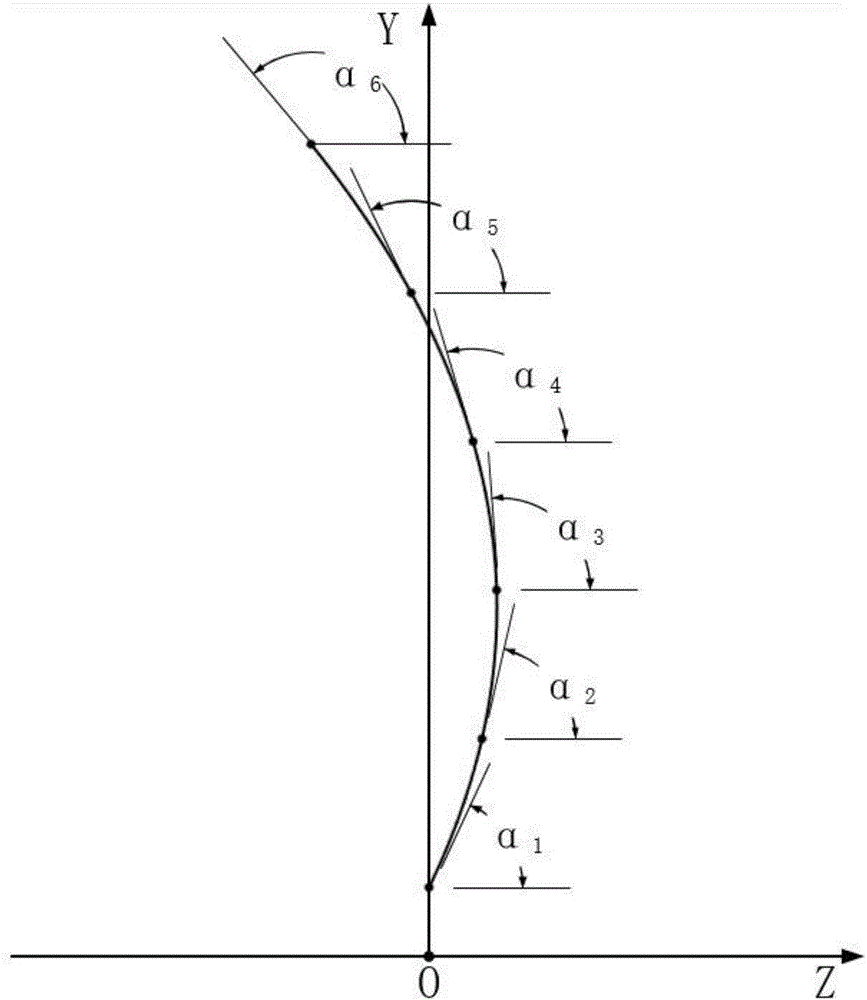

[0051] The diameter of the impeller in this embodiment is 352 mm, and the hub ratio is 0.27. The projection line of the spatial accumulation line of the blade on the YOZ plane (that is, the meridian plane) is a cubic spline curve, and the projected grazing angle on the projection line changes with the change of the blade height percentage. The projection line passes through six control point (1~6), the position coordinates of these 6 control points are (coordinate format is (corresponding blade height percentage, blade stacking point meridional grazing angle), meridian grazing angle is projected grazing angle): (0%, 84.11°), (20%, 87.39°), (40%, 90.68°), (60%, 93.96°), (80%, 97.23°), (100%, 100.44°).

Embodiment 2

[0053] The diameter of the impeller in this embodiment is 497 mm, and the hub ratio is 0.262. The projection line of the spatial accumulation line of the blade on the YOZ plane (that is, the meridian plane) is a cubic spline curve, and the projected grazing angle on the projection line changes with the change of the blade height percentage. The projection line passes through six control point (1~6), the position coordinates of these 6 control points are (coordinate format is (corresponding leaf height percentage, leaf stacking point meridional sweep angle)): (0%, 80.95°), (20%, 85.73°), (40%, 90.57°), (60%, 95.40°), (80%, 100.15°), (100%, 104.77°).

Embodiment 3

[0055] The diameter of the impeller in this embodiment is 900 mm, and the hub ratio is 0.211. The projection line of the spatial accumulation line of the blade on the YOZ plane (that is, the meridian plane) is a cubic spline curve, and the projected grazing angle on the projection line changes with the change of the blade height percentage. The projection line passes through six control point (1~6), the position coordinates of these 6 control points are (coordinate format is (corresponding leaf height percentage, leaf stacking point meridional sweep angle)): (0%, 80.68°), (20%, 85.70°), (40%, 90.78°), (60%, 95.85°), (80%, 100.82°), (100%, 105.64°).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com