A biomass burning furnace

A biomass combustion furnace and combustion furnace technology, applied in the direction of combustion equipment, combustion method, combustion ignition, etc., can solve the problems of heat energy consumption, insufficient fuel combustion, and furnace bridge cannot be rotated, so as to reduce the waste of heat energy and improve Thermal efficiency, effect of volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

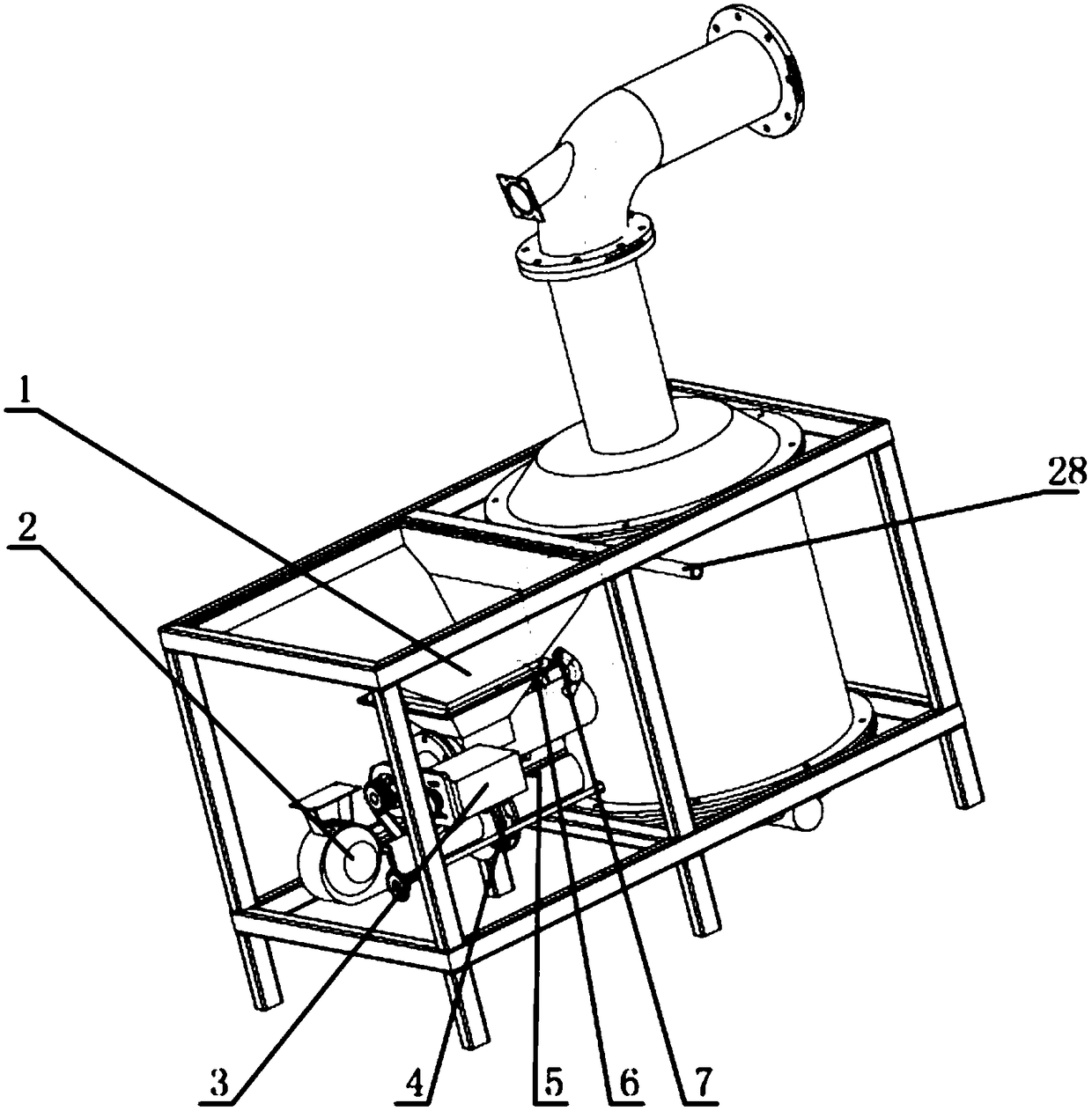

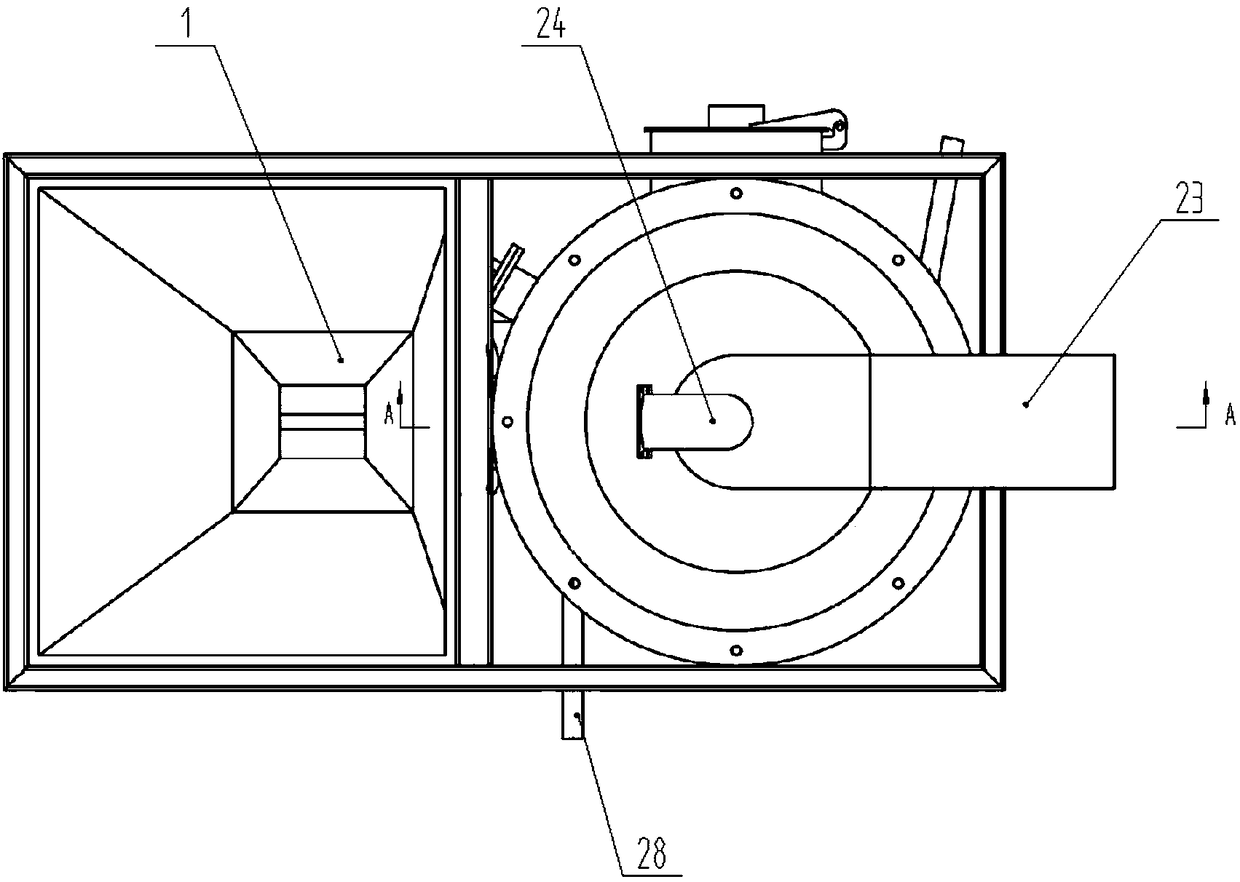

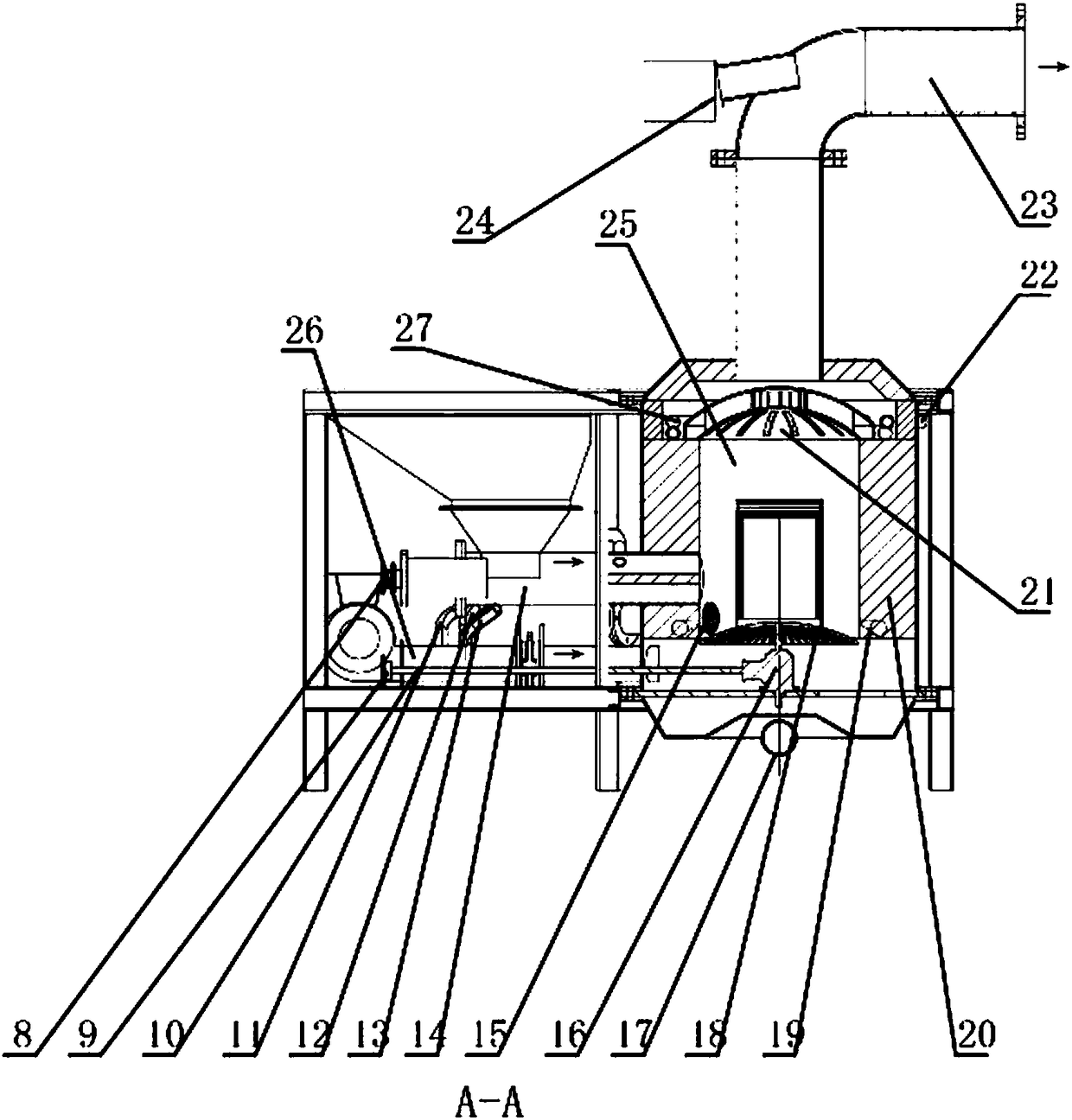

[0022] The present invention and its specific implementations will be described in further detail below in conjunction with the accompanying drawings.

[0023] see Figure 1-3 , the present invention comprises feeding device, oxygen supply ignition device and combustion furnace, is characterized in that:

[0024] A. described feeding device comprises feeding hopper 1, feeding pipe 14, sprocket wheel 8 and motor 3, and the lower end of feeding hopper 1 is communicated with feeding pipe 14, and feeding screw shaft is housed in this feeding pipe, and the screw shaft of this screw shaft One end is connected with the motor 3 through the sprocket 8, and one end of the feed pipe is communicated with the furnace 25;

[0025] B. described oxygen supply ignition device comprises oxygen supply fan 2, oxygen supply pipe 26, butterfly valve 4, one end of oxygen supply pipe 26 communicates with oxygen supply blower fan 2, and the other end corresponds to the bottom of furnace bridge 18 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com