Automatic assembling equipment for storage battery liquid-filled hole plug

A technology of automatic assembly and liquid hole plugging, applied in the field of automation, can solve the problems of slow installation efficiency, a lot of labor, uneven quality, etc., and achieve the effect of convenient control, convenient processing or assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

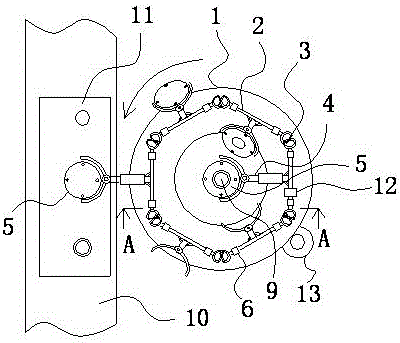

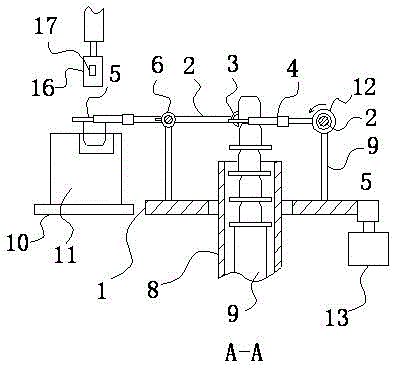

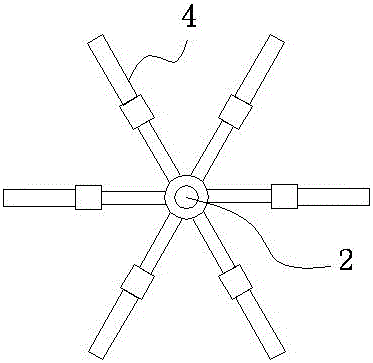

[0020] Such as figure 1 , 2 As shown, an automatic battery liquid hole plug assembly equipment includes a frame, a turntable 1, a liquid hole plug lifting frame and a battery conveyor belt 16 for transferring batteries. The frame is a regular hexagon frame formed by connecting the rotating shafts 2 end to end, and the rotating shafts are connected to each other through the cross-shaft universal joint 3, that is, the rotating shafts are used as the sides of the hexagon. Each rotating shaft is provided with a manipulator 4 for grabbing the liquid hole plug. The jaws of the manipulator are open and closed arc-shaped jaws, so as to adapt to the shape of the liquid hole plug 5. A telescopic mechanical mechanism is connected between the gripper and the rotating shaft. arm for easy adjustment of its working range. Such as image 3 As shown, when all the axes are in a straight line, the angles between the manipulators are equal, and the sum of the angles between the manipulators is...

Embodiment 2

[0024] Such as Figure 4 , 5 As shown, the difference from Embodiment 1 is that the driving mode of the rotating shaft is that a bevel gear 15 is arranged on one of the rotating shafts, a rotating shaft drive motor for driving the gear to rotate is arranged on the rotating disk, and a motor shaft is arranged on the shaft of the motor. Bevel gear meshing bevel gears.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com