Preparation method of expanded graphite/silicon@carbon negative electrode material for lithium ion batteries

A lithium-ion battery and carbon negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of insufficient bonding force between silicon nanoparticles and expanded graphite, uneven mixing of silicon nanoparticles expanded graphite and silicon nanoparticles, Eliminate problems such as silicon nanoparticle shedding, achieve excellent cycle stability and rate performance, reduce exposure, and buffer volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

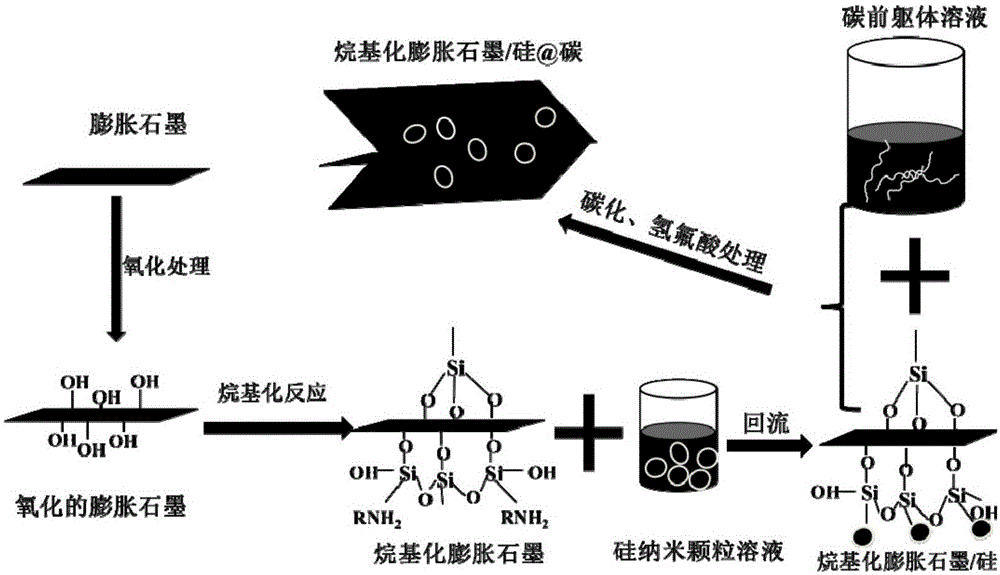

[0035] A preparation method of expanded graphite / silicon@carbon negative electrode material for lithium ion battery, carried out according to the following method (such as figure 1 shown):

[0036] (1) Add 500mg of expanded graphite to 500ml of nitric acid / sulfuric acid mixed acid solution with a volume ratio of 1 / 1 and soak for 4h, wash to neutral to obtain oxidized expanded graphite, soak the oxidized expanded graphite in 500ml of absolute ethanol 2h to obtain the oxidized expanded graphite ethanol solution mixture.

[0037] (2) The triaminopropyltriethoxysilane coupling agent of 2mg is added in the oxidized expanded graphite ethanol solution mixture obtained in step (1) and stirred for 6h to obtain the alkylated expanded graphite ethanol solution mixture, and then 100mg Silicon nanoparticles are added to the alkylated expanded graphite ethanol solution mixture, stirred and refluxed in a 70° C. water bath for 6 hours to obtain an alkylated expanded graphite / silicon mixed s...

Embodiment 2

[0043] A preparation method of expanded graphite / silicon@carbon negative electrode material for lithium ion battery, carried out as follows:

[0044] (1) Add 200mg of expanded graphite to 100ml of nitric acid / sulfuric acid mixed solution with a volume ratio of 1 / 2 and soak for 8h, wash to neutral to obtain oxidized expanded graphite; soak the oxidized expanded graphite in 40ml of absolute ethanol Soak for 6h to obtain the oxidized expanded graphite ethanol solution mixture.

[0045] (2) Add 5 mg of triaminotriethoxysilane coupling agent to the oxidized expanded graphite ethanol solution mixture obtained in step (1) and stir for 3 hours to obtain the alkylated expanded graphite ethanol solution mixture, and then add 100 mg of silicon nano The particles are added to the alkylated expanded graphite ethanol solution mixture, stirred and refluxed in a water bath at 80° C. for 8 hours, and the alkylated expanded graphite / silicon mixed solution can be obtained. After cooling to room...

Embodiment 3

[0052] A preparation method of expanded graphite / silicon@carbon negative electrode material for lithium ion battery, carried out as follows:

[0053] (1) After adding 100mg of expanded graphite to 20ml of nitric acid / sulfuric acid mixed solution with a volume ratio of 1 / 5 and soaking for 16h, wash to neutrality; after washing to neutrality, oxidized expanded graphite is obtained, and the oxidized expanded graphite is soaked in 8h in 10ml absolute ethanol obtains the oxidized expanded graphite ethanol solution mixture;

[0054] (2) Add 20 mg of triaminotriethoxysilane coupling agent to the oxidized expanded graphite ethanol solution mixture obtained in step (1) and stir for 9 hours to obtain the alkylated expanded graphite ethanol solution mixture, and then add 50 mg of silicon nano The particles are added to the mixture of alkylated expanded graphite ethanol solution, stirred and refluxed in a water bath at 100°C for 4 hours to obtain an alkylated expanded graphite / silicon mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com