Industrial production method for potato minituber by using foamed plastic as substrate

A technology of foamed plastics and production methods, applied in the field of agriculture, can solve the problems of not being suitable for large-scale production and planting, the inability to provide potato seeds, and the high probability of non-toxic purebreds, so as to improve the working environment and labor intensity, and improve space utilization. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation method of the foamed plastic matrix: in the preparation process of the foamed plastic or resin, nutritional elements suitable for potato growth are added, and the foamed plastic matrix is processed.

[0061] The preparation method of a thermoplastic resin foamed plastic matrix includes the following steps: mixing raw materials with corresponding foaming agents and special trace elements, extruding raw materials through an extruder to pelletize, and the raw materials are polyethylene, polypropylene or polypropylene. Styrene, to obtain foamed particles, and then inject the prepared foamed particles into the mold for heat sealing, and then pickle the opening to become a matrix block that can absorb water and retain water, and obtain a foamed plastic matrix. The added weight of foaming agent is 1%-5% of the weight of raw materials. The incorporation ratio of the trace elements necessary for potato growth is 0.4%-2% of the raw material weight.

[0062] The...

Embodiment 1

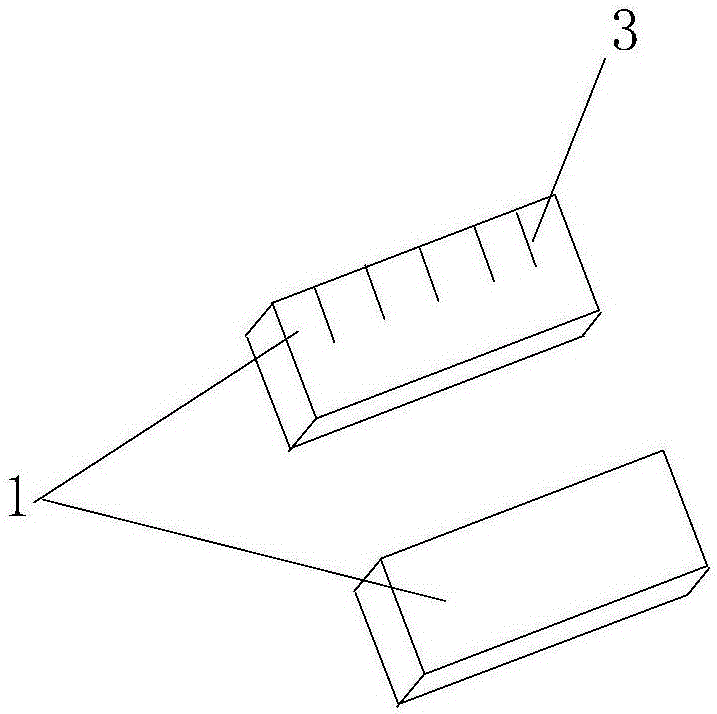

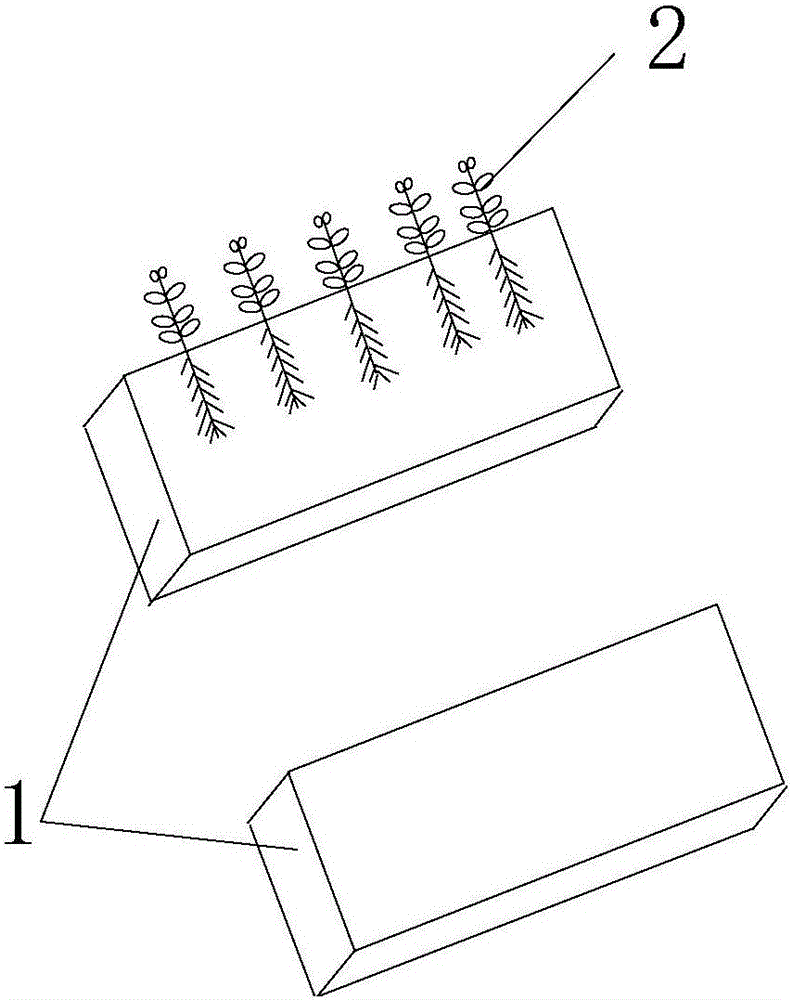

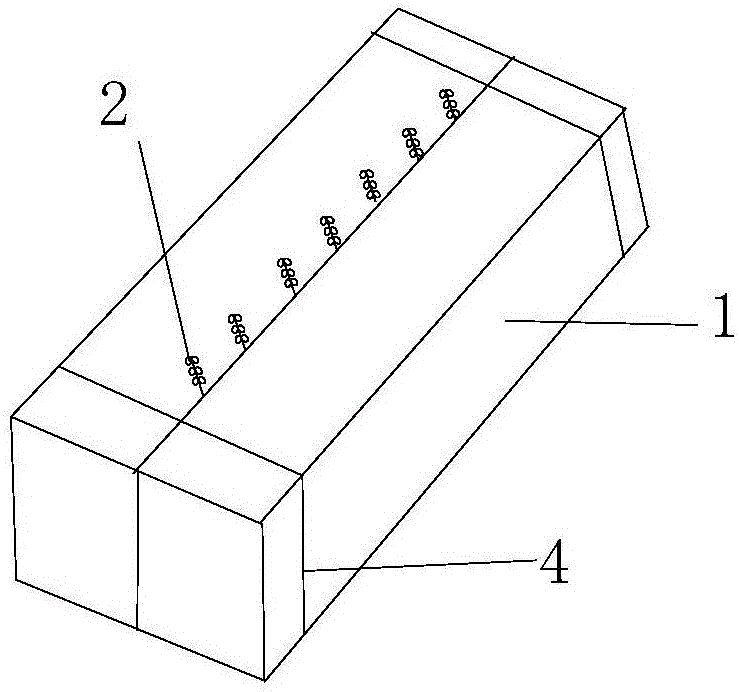

[0081] A foamed plastic matrix, the foamed plastic matrix contains nutrients needed for potato growth, the foamed plastic matrix is divided into a first foamed plastic matrix and a second foamed plastic matrix arranged side by side, and the potato test tube seedlings are clamped in the second Between the first foamed plastic substrate and the second foamed plastic substrate. At least one portion of the first foamed plastic substrate and the second foamed plastic substrate that is in contact with the potato plantlets is provided with a notch that is concave toward the inside of the foamed plastic substrate. The notches are arranged along the height direction of the foamed plastic matrix, and the depth of the notches is 2mm. The shapes of the first foamed plastic matrix and the second foamed plastic matrix are both cuboid. The foamed plastic substrate is an open foamed plastic, the water absorption is 35 times the weight of the substrate, the 5-day water retention is 70%, and...

Embodiment 2

[0089] A foamed plastic matrix, the foamed plastic matrix contains nutrients needed for potato growth, the foamed plastic matrix is divided into a first foamed plastic matrix and a second foamed plastic matrix arranged side by side, and the potato test tube seedlings are clamped in the second Between the first foamed plastic substrate and the second foamed plastic substrate. At least one portion of the first foamed plastic substrate and the second foamed plastic substrate that is in contact with the potato plantlets is provided with a notch that is concave toward the inside of the foamed plastic substrate. The notches are arranged along the height direction of the foamed plastic matrix, and the depth of the notches is 1mm. The shapes of the first foamed plastic matrix and the second foamed plastic matrix are both cuboid. The foamed plastic substrate is an open foamed plastic, the water absorption is 30 times the weight of the substrate, the 5-day water retention is 60%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com