High foaming whole egg powder preparation method

A technology of whole egg powder and foamability, which is applied in the field of preparation of high foaming whole egg powder, can solve the problem that the improvement of the foaming power and foam stability of whole egg powder or egg white liquid is not very large, and the whole egg powder The brewing property is not very good, the time of enzymatic hydrolysis is long, etc., to achieve the effect of good appearance, easy industrial production and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

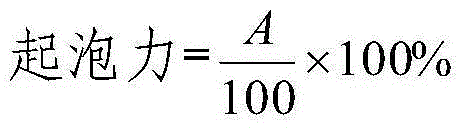

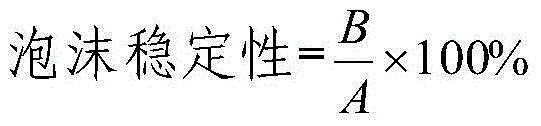

[0030] The preparation method of high-foaming whole egg powder comprises the following steps: (1) taking fresh eggs, breaking the shell to get the whole egg liquid, stirring evenly and then filtering to remove impurities; (2) adding the whole egg liquid obtained through the step (1) Add neutral protease aqueous suspension and papain aqueous suspension respectively in the medium, make the addition amount of neutral protease and papain reach 1500u / g and 1000u / g respectively, enzymolysis 120 minutes under the temperature of 45~50 ℃; ( 3) Add maltodextrin powder to the whole egg liquid after enzymolysis to make its mass fraction reach 3%, and stir evenly; (4) Pasteurize the mixture obtained through step (3), and the sterilization temperature is 63 ~65°C, the sterilization time is 5 minutes; (5) Spray-dry the pasteurized mixture, the inlet air temperature is 140°C-160°C, and the outlet air temperature is 74°C-78°C; (6) Collect the spray Dry the obtained whole egg powder, pass it th...

Embodiment 2

[0033] The preparation method of high-foaming whole egg powder comprises the following steps: (1) taking fresh eggs, breaking the shell to get the whole egg liquid, stirring evenly and then filtering to remove impurities; (2) adding the whole egg liquid obtained through the step (1) Add neutral protease aqueous suspension and papain aqueous suspension respectively in the medium, make the addition amount of neutral protease and papain reach 2000u / g and 1000u / g respectively, enzymolysis 120 minutes under the temperature of 45~50 ℃; ( 3) Add maltodextrin powder to the whole egg liquid after enzymolysis to make its mass fraction reach 3%, and stir evenly; (4) Pasteurize the mixture obtained through step (3), and the sterilization temperature is 63 ~65°C, the sterilization time is 5 minutes; (5) Spray-dry the pasteurized mixture, the inlet air temperature is 140°C-160°C, and the outlet air temperature is 74°C-78°C; (6) Collect the spray Dry the obtained whole egg powder, pass it th...

Embodiment 3

[0036]The preparation method of high-foaming whole egg powder comprises the following steps: (1) taking fresh eggs, breaking the shell to get the whole egg liquid, stirring evenly and then filtering to remove impurities; (2) adding the whole egg liquid obtained through the step (1) Add neutral protease aqueous suspension and papain aqueous suspension respectively in the medium, make the addition amount of neutral protease and papain reach 1500u / g and 1500u / g respectively, enzymolysis 120 minutes under the temperature of 45~50 ℃; ( 3) Add maltodextrin powder to the whole egg liquid after enzymolysis to make its mass fraction reach 3%, and stir evenly; (4) Pasteurize the mixture obtained through step (3), and the sterilization temperature is 63 ~65°C, the sterilization time is 5 minutes; (5) Spray-dry the pasteurized mixture, the inlet air temperature is 140°C-160°C, and the outlet air temperature is 74°C-78°C; (6) Collect the spray Dry the obtained whole egg powder, pass it thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com