A kind of gas purification device and purification method for deaerator

A gas purification and degasser technology, applied in chemical instruments and methods, separation methods, combined devices, etc., can solve problems such as clogging of chromatographs, damage to precision instruments, and confusion, and achieve the effect of easy aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

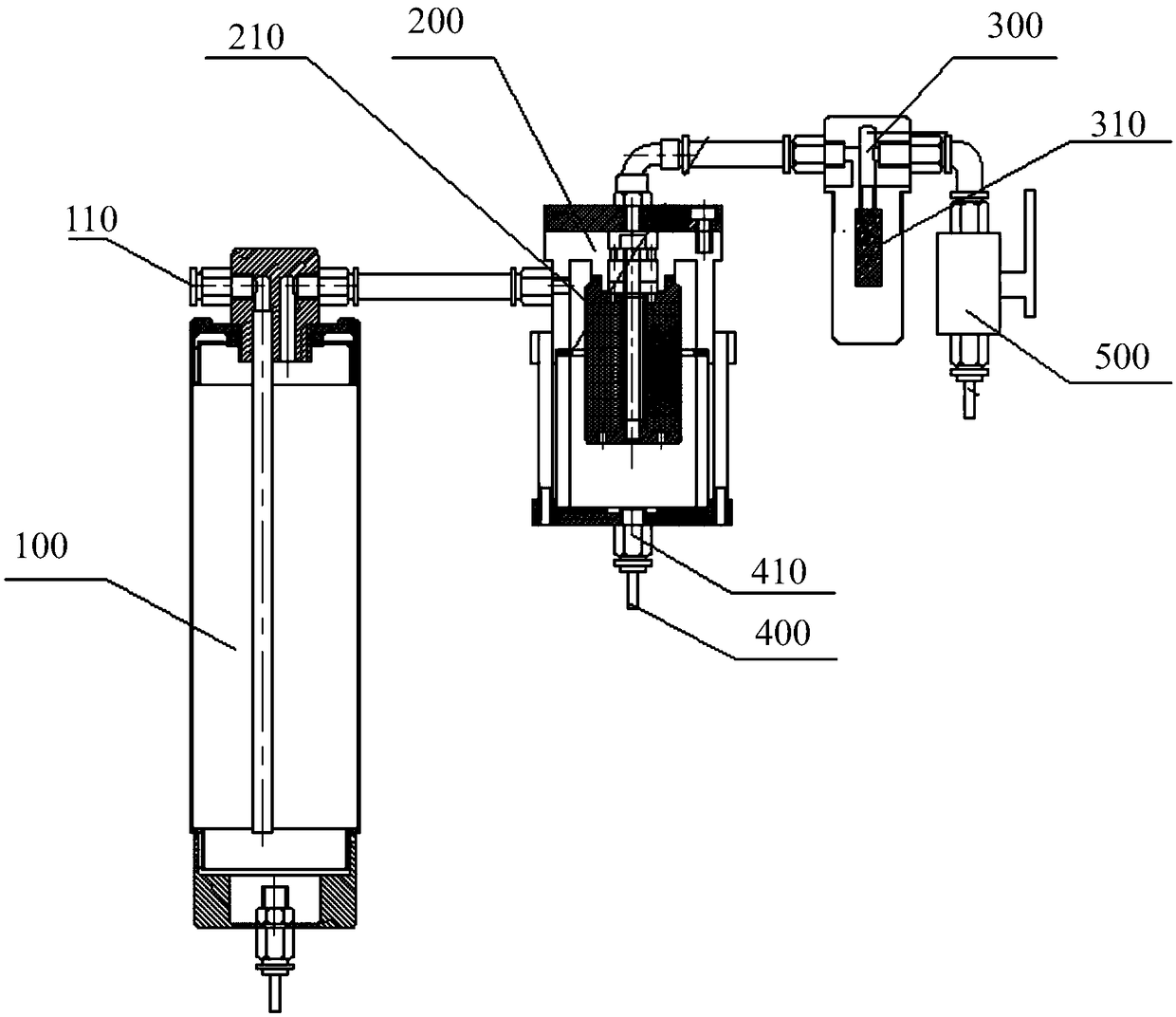

[0032] like figure 1 As shown, a gas purification device for a deaerator provided by the present invention includes: a water removal tank 100 , a decontamination tank 200 and a cleaning tank 300 .

[0033] The water removal tank 100 includes an air intake line 110 that penetrates into the bottom of the tank, and is mainly used to remove a large amount of water in the gas. During the flow of the mixed gas from bottom to top, condensation will occur due to different substances in the gas, different quality and liquefaction point. , the condensation effect of the water is the best here, and some impurities of the components will also be incorporated into the water. As a preferred material for the intake pipe, the non-hydrophilic and lipophilic Teflon material, the condensed water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com