An integral forming device and forming method for the bottom of a spacecraft fuel storage tank

An integral forming and spacecraft technology, applied in the field of spacecraft storage tank forming technology, can solve the problems of poor quality of the bottom of the spacecraft fuel storage tank, and achieve the effect of increasing the payload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the present invention will be further described in conjunction with the drawings and embodiments.

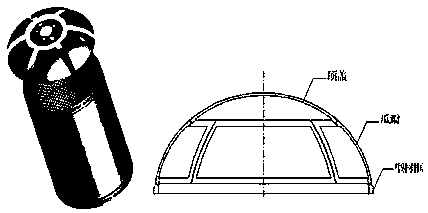

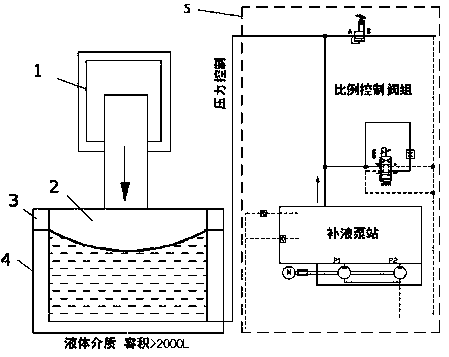

[0023] Such as figure 2 As shown, the overall forming device for the bottom of the spacecraft fuel tank provided by the present invention includes: a press system 1, a punch 2, a blank holder 3, a liquid-filled chamber 4, and a large-volume liquid pressure control system 5. The liquid-filled chamber 4 is filled with liquid, and the sheet material is covered on the top of the liquid-filled chamber 4, and the sheet material is pressed by the blank holder 3; , The sheet is deep-formed under the support of liquid pressure.

[0024] The movement speed and direction of the punch are controlled by the press system 1 . In this embodiment, the press system adopts a 10,000-ton ordinary double-acting hydraulic press to provide driving force for deep drawing of large box bottoms. The shape of the punch is determined according to the size of the bottom of the spacecra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com