Reduction drive wheel and robot using the reduction drive wheel

A driving wheel and reducer technology, applied in the field of robots, can solve the problems that restrict the promotion and application of omnidirectional mobile robots, increase the axial size of the power transmission system, and the friction driving ability of the driving wheel is weak. Compact structure, easy to manufacture and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

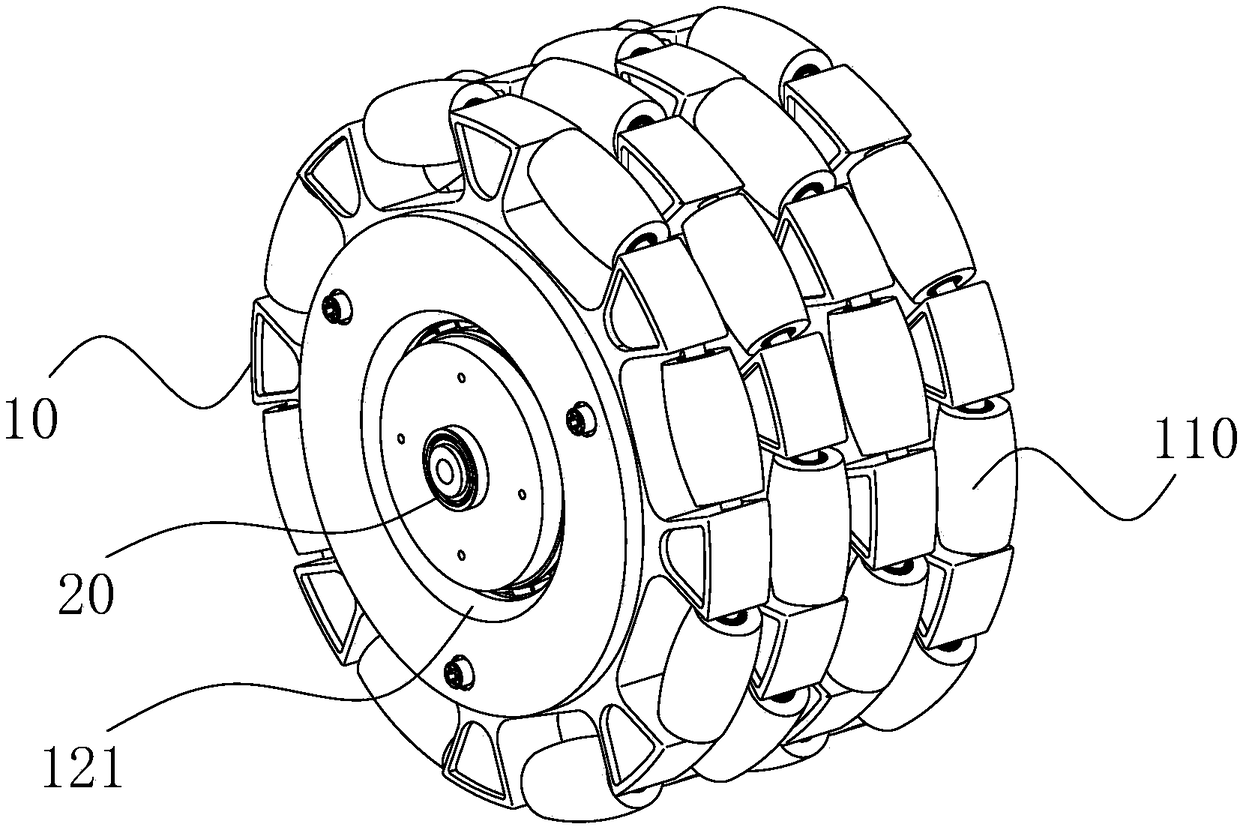

[0035] Please refer to figure 1 , the present embodiment provides a reduction drive wheel 1 , including an omnidirectional wheel body 10 and a reducer 20 .

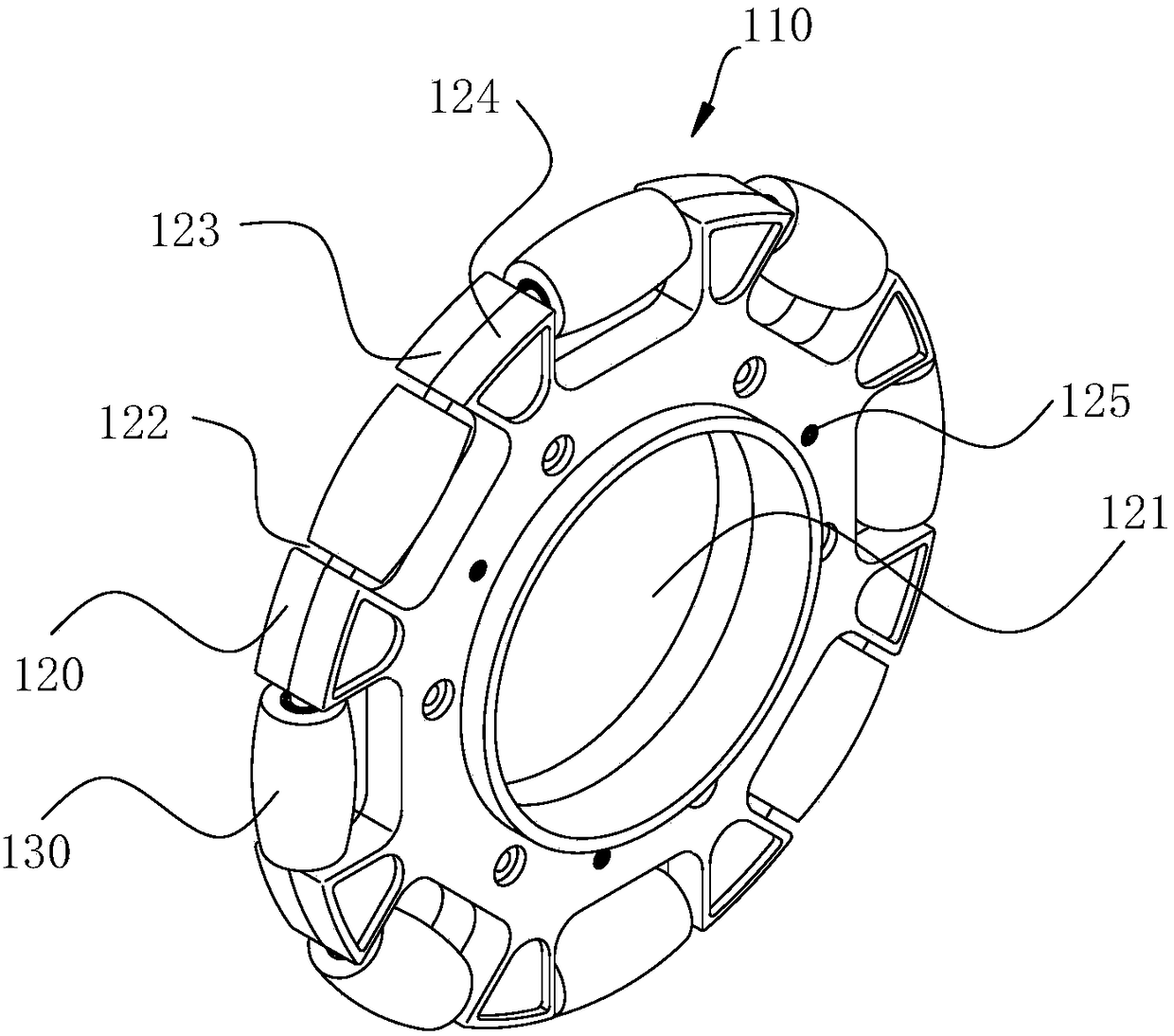

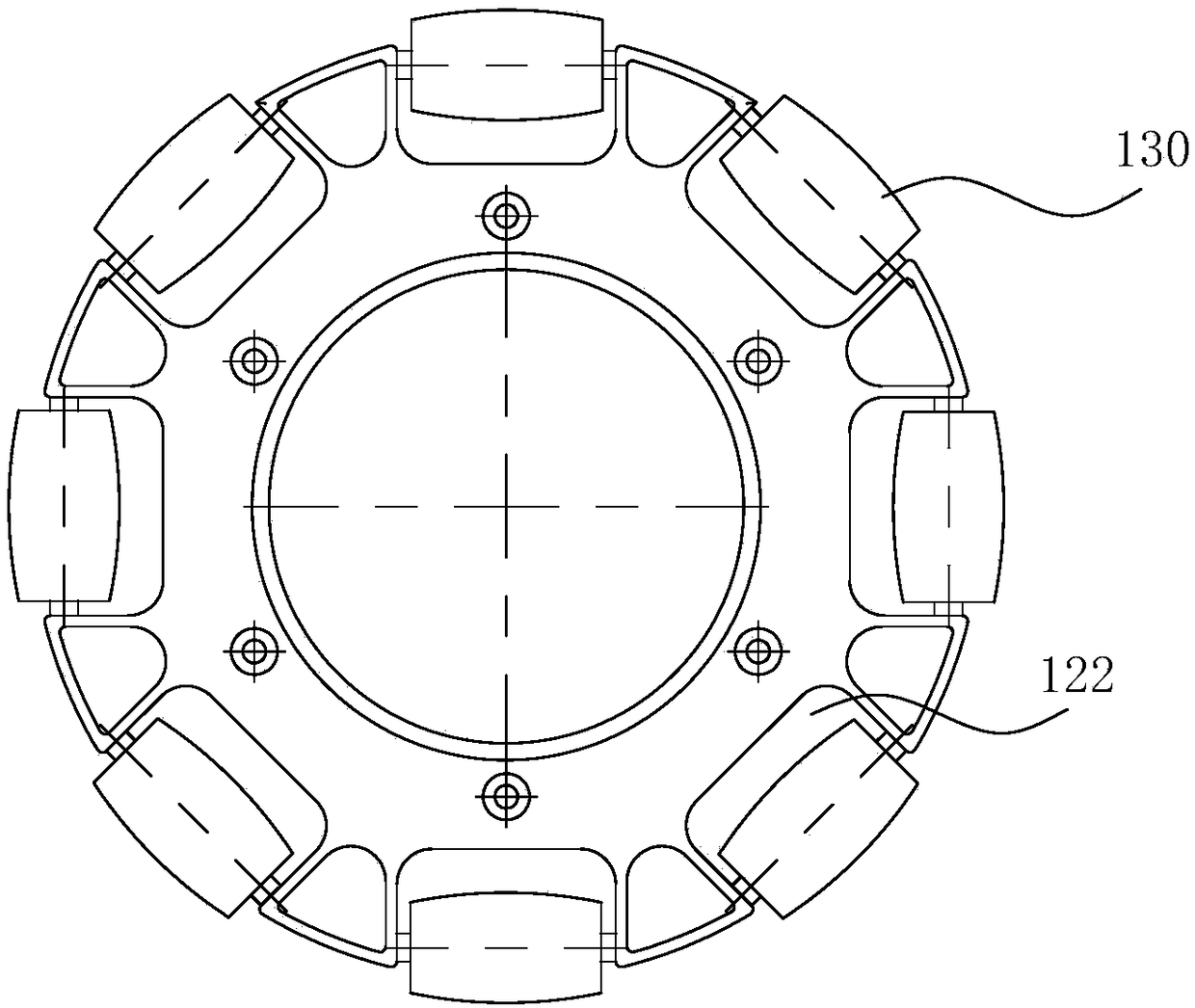

[0036] Such as figure 2 As shown, the omnidirectional wheel body 10 includes an omnidirectional wheel assembly 110 , and the omnidirectional wheel assembly 110 includes a hub 120 and a plurality of rollers 130 .

[0037] Such as figure 2 As shown, the hub 120 is provided with mounting holes 121 , and the edge of the hub 120 is provided with a plurality of through grooves 122 , and the through grooves 122 are evenly distributed along the circumference of the hub 120 . In order to balance the force of the omnidirectional wheel assembly 110 during movement, the mounting hole 121 is opened at the center of the hub 120 .

[0038] In this embodiment, the mounting hole 121 on the hub 120 can be in various forms, either a through hole or a blind hole. As an optional solution of this embodiment, the installation hole 121 may...

no. 2 example

[0063] This embodiment provides a robot, including a robot body and the reduction drive wheel 1 of the first embodiment.

[0064] In this embodiment, the deceleration drive wheel 1 is connected to the robot body through a connector 250, and the deceleration drive wheel 1 is externally connected to a motor 251. After the motor 251 is energized, it can drive the deceleration drive wheel 1 to rotate, and the deceleration drive wheel 1 drives the robot body to move to realize robot walking. . As an alternative to this embodiment, such as Figure 7 As shown, the connecting piece 250 can adopt but not limited to an L-shaped connecting plate. The L-shaped connecting plate includes a first connecting plate and a second connecting plate, the first connecting plate is connected with the robot body, and the second connecting plate is connected with the reduction drive wheel 1 .

[0065] Beneficial effects of this embodiment: this embodiment provides a robot, which has a deceleration dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com