Sewage purification equipment and purification method based on chemical neutralization method and nanofiltration technology

A nano-filtration and sewage purification technology, applied in chemical instruments and methods, neutralized water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of high treatment cost, long process flow, complicated control, etc., and achieve purification effect Good, improved stirring uniformity rate, high integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

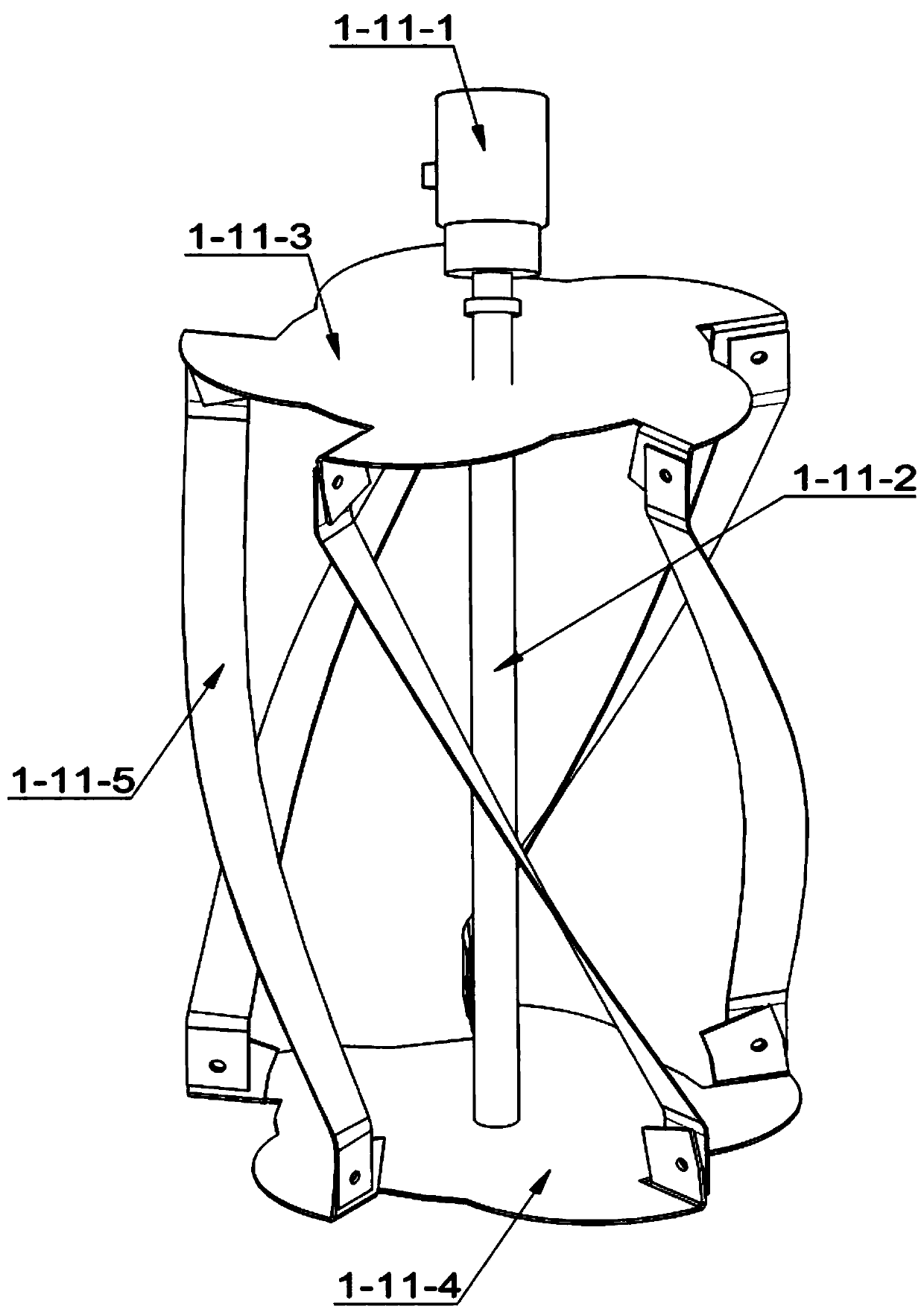

[0048] According to the following steps to manufacture the stirring rotary teeth 1-11-5 of the present invention, and by weight fraction:

[0049] Step 1: Add 444 parts of ultrapure water with a conductivity of 0.44μS / cm into the reactor, start the stirrer in the reactor at a speed of 104rpm, start the heating pump, and raise the temperature in the reactor to 74°C; (E)-3-(3,4-dimethoxyphenyl)-2-ethyl cyanoacrylate 74 parts, 3,5-bis[(2,4-diaminophenyl)azo]-4 - 94 parts of sodium toluenesulfonate, 144 parts of 3-(4-hydroxy-3-methoxyphenyl) lanosterol-2-acrylate, stir until completely dissolved, adjust the pH value to 4.4, and turn the stirrer speed Adjust to 144rpm, the temperature is 104°C, and the esterification reaction takes 24 hours;

[0050] Step 2: Take 94 parts of 3,5-bis(1,1-dimethylethyl)-4-hydroxybenzoic acid-2,4-bis(1,1-dimethylpropyl)phenyl ester, L 84 parts of (-)-1-(4-methylthiophenyl)-2-amino-1,3-propanediol were pulverized, and the particle size of the powder ...

Embodiment 2

[0055] According to the following steps to manufacture the stirring rotary teeth 1-11-5 of the present invention, and by weight fraction:

[0056] Step 1: Add 1414 parts of ultrapure water with a conductivity of 0.84μS / cm into the reactor, start the stirrer in the reactor at a speed of 244rpm, start the heating pump, and raise the temperature in the reactor to 94°C; 144 parts of (E)-3-(3,4-dimethoxyphenyl)-2-ethyl cyanoacrylate, 3,5-bis[(2,4-diaminophenyl)azo]-4 - 144 parts of sodium toluenesulfonate, 344 parts of 3-(4-hydroxy-3-methoxyphenyl) lanosterol-2-acrylate, stir until completely dissolved, adjust the pH value to 8.4, and turn the stirrer speed Adjust to 244rpm, the temperature is 174°C, and the esterification reaction is 34 hours;

[0057] Step 2: Take 204 parts of 3,5-bis(1,1-dimethylethyl)-4-hydroxybenzoic acid-2,4-bis(1,1-dimethylpropyl)phenyl ester, L 144 parts of (-)-1-(4-methylthiophenyl)-2-amino-1,3-propanediol were pulverized, and the particle size of the po...

Embodiment 3

[0062] According to the following steps to manufacture the stirring rotary teeth 1-11-5 of the present invention, and by weight fraction:

[0063] Step 1: Add 914 parts of ultrapure water with a conductivity of 0.54μS / cm into the reactor, start the stirrer in the reactor at a speed of 154rpm, start the heating pump, and raise the temperature in the reactor to 84°C; 104 parts of (E)-3-(3,4-dimethoxyphenyl)-2-ethyl cyanoacrylate, 3,5-bis[(2,4-diaminophenyl)azo]-4 - 134 parts of sodium toluenesulfonate, 234 parts of 3-(4-hydroxy-3-methoxyphenyl) lanosterol-2-acrylate, stir until completely dissolved, adjust the pH value to 5.4, and turn the stirrer speed Adjust to 184rpm, the temperature is 134°C, and the esterification reaction is 32 hours;

[0064] Step 2: Take 154 parts of 3,5-bis(1,1-dimethylethyl)-4-hydroxybenzoic acid-2,4-bis(1,1-dimethylpropyl)phenyl ester, L 104 parts of (-)-1-(4-methylthiophenyl)-2-amino-1,3-propanediol were pulverized, and the particle size of the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com