Liquid cement grinding aid enhancer and preparation method thereof

A grinding aid enhancer and cement technology, which is applied in the field of cement manufacturing, can solve the problems of complex production process, influence on cement properties, corrosion of building metal, etc., and achieve the effect of simple production method, stable product quality and enhanced cement strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

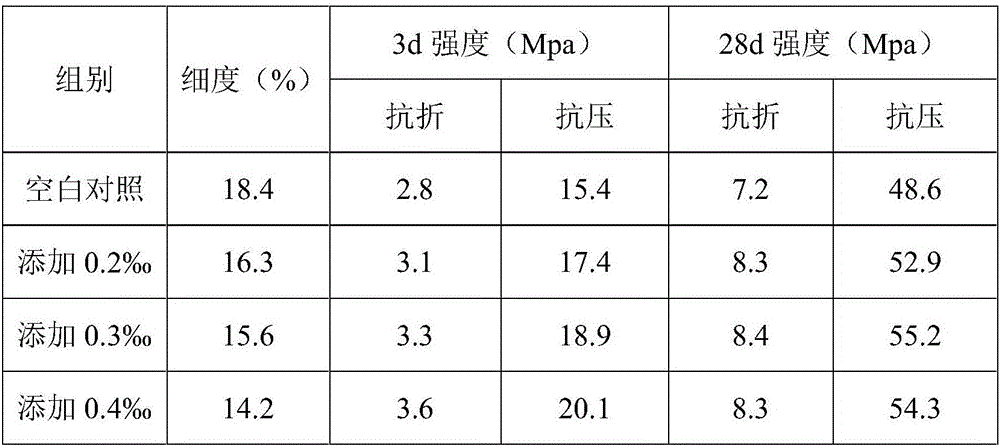

Embodiment 1

[0020] A liquid cement grinding aid, made of the following raw materials in parts by weight: 20-32 parts of triethanolamine, 8 parts of ethylene glycol, 4 parts of potassium fulvic acid, 6 parts of sodium citrate, 2 parts of α-terpineol 10 parts of acetophenone, 3 parts of polydimethylsiloxane, 4 parts of polytetrahydrofuran glycol, 1 part of isofusterol, 2 parts of sulfobetaine, and 24 parts of water.

[0021] The preparation method of described liquid cement grinding aid reinforcing agent comprises the following steps:

[0022] 1) Weigh triethanolamine, ethylene glycol, acetophenone, and polydimethylsiloxane according to the formula, add them to the reactor in sequence and mix them, and stir them fully at 50°C for 2 hours to obtain the mixture for later use;

[0023] 2) Weigh potassium fulvic acid, sodium citrate, α-terpineol, polytetrahydrofuran diol, isofucosterol, and sultaine according to the formula, add to the water of the formula amount, and mix thoroughly at 60°C St...

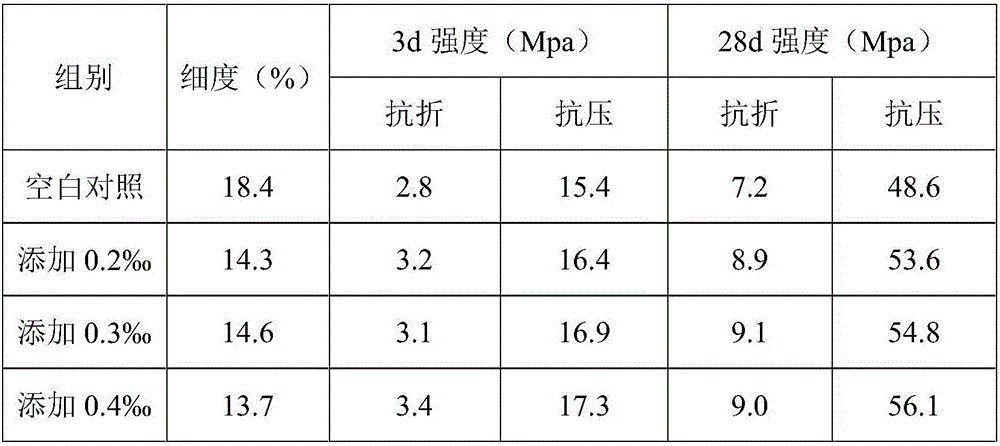

Embodiment 2

[0029] A liquid cement grinding aid, made of the following raw materials in parts by weight: 20 parts of triethanolamine, 14 parts of ethylene glycol, 10 parts of potassium fulvic acid, 10 parts of sodium citrate, 6 parts of α-terpineol, 20 parts of acetophenone, 7 parts of polydimethylsiloxane, 8 parts of polytetrahydrofuran glycol, 5 parts of isofusterol, 6 parts of sulfobetaine, and 36 parts of water.

[0030] The preparation method of described liquid cement grinding aid reinforcing agent comprises the following steps:

[0031] 1) Weigh triethanolamine, ethylene glycol, acetophenone, and polydimethylsiloxane according to the formula, add them to the reactor one by one and mix them, stir them fully at 60°C for 3 hours, and obtain the mixture for later use;

[0032] 2) Weigh potassium fulvic acid, sodium citrate, α-terpineol, polytetrahydrofuran diol, isofucosterol, and sultaine according to the formula, add it to the water of the formula amount, and mix thoroughly at a temp...

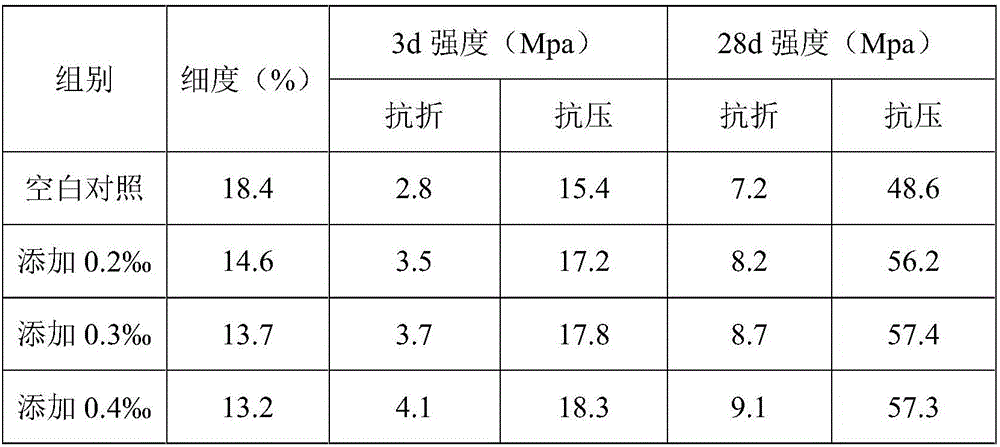

Embodiment 3

[0038] A liquid cement grinding aid, made of the following raw materials in parts by weight: 24 parts of triethanolamine, 10 parts of ethylene glycol, 6 parts of potassium fulvic acid, 7 parts of sodium citrate, 3 parts of α-terpineol, 14 parts of acetophenone, 4 parts of polydimethylsiloxane, 5 parts of polytetrahydrofuran glycol, 2 parts of isofusterol, 3 parts of sulfobetaine, and 28 parts of water.

[0039] The preparation method of described liquid cement grinding aid reinforcing agent comprises the following steps:

[0040] 1) Weigh triethanolamine, ethylene glycol, acetophenone, and polydimethylsiloxane according to the formula, add them to the reactor in sequence and mix them, and stir them fully at 50°C for 2 hours to obtain the mixture for later use;

[0041] 2) Weigh potassium fulvic acid, sodium citrate, α-terpineol, polytetrahydrofuran diol, isofucosterol, and sultaine according to the formula, add to the water of the formula amount, and mix thoroughly at 60°C St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com