Application of hyperbranched polyamide in removing formaldehyde in urea-formaldehyde resin adhesive

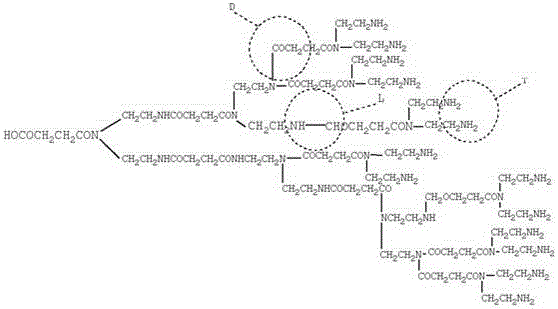

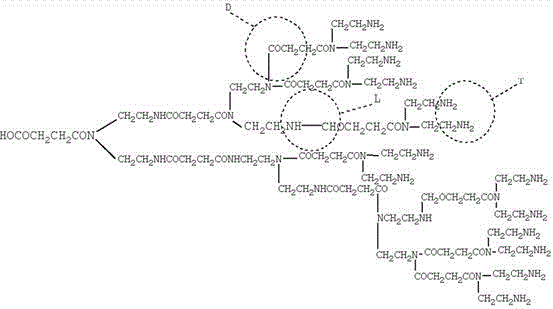

A technology of hyperbranched polyamide and branched units, which is applied in adhesives, adhesive additives, aldehyde/ketone condensation polymer adhesives, etc., can solve the problems of less active groups and small molecular weight of formaldehyde scavenger, and achieve active The effect of abundant groups, reducing the content of free formaldehyde, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a more detailed statement of the specific implementation methods of the present invention, the purpose of which is to illustrate the concept and characteristics of the present invention, and not to limit the protection scope of the present invention. All equivalent changes or modifications made according to the spirit of the present invention shall fall within the protection scope of the present invention.

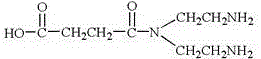

[0019] (1) Use a 10mL pipette to pipette 5.40mL (0.05mol) of diethylenetriamine, place it in a 250mL three-neck flask containing 30mL of anhydrous methanol, and accurately weigh 5.000g (0.05mol) of diethylene triamine with an electronic balance Place the acid anhydride in a 500mL beaker, add 150mL of anhydrous methanol to the beaker, and stir to fully dissolve the succinic anhydride. The three-necked flask is fixed on the stirrer, the three-necked flask is placed in an ice-water bath, the fully dissolved succinic anhydride is placed in a constant pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com