Method for preparing high-heat-conductivity boron nitride reinforced polymer based composite material

A composite material and polymer technology, which is applied in the field of preparation of high thermal conductivity boron nitride reinforced polymer matrix composite materials, can solve the problems of complex process, long cycle time, poor uniform dispersion of polymers, etc., and achieve excellent thermal conductivity, molding Low shrinkage and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The preparation method of composite material of the present invention comprises the following steps:

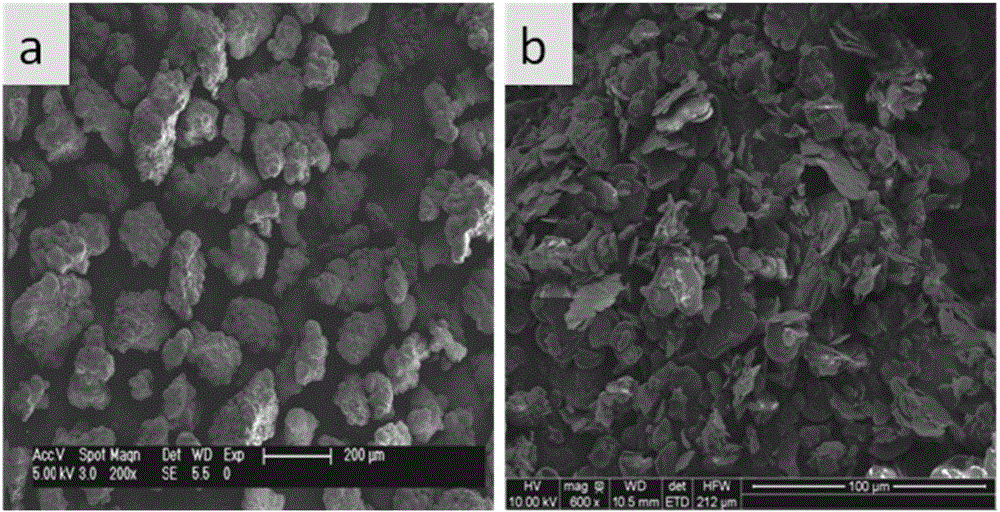

[0066] a) under the action of a double-center mixing and dispersing machine, mixing layered hexagonal boron nitride powder and polymer powder, so that the polymer powder evenly adheres to the surface of the boron nitride powder to obtain a mixture;

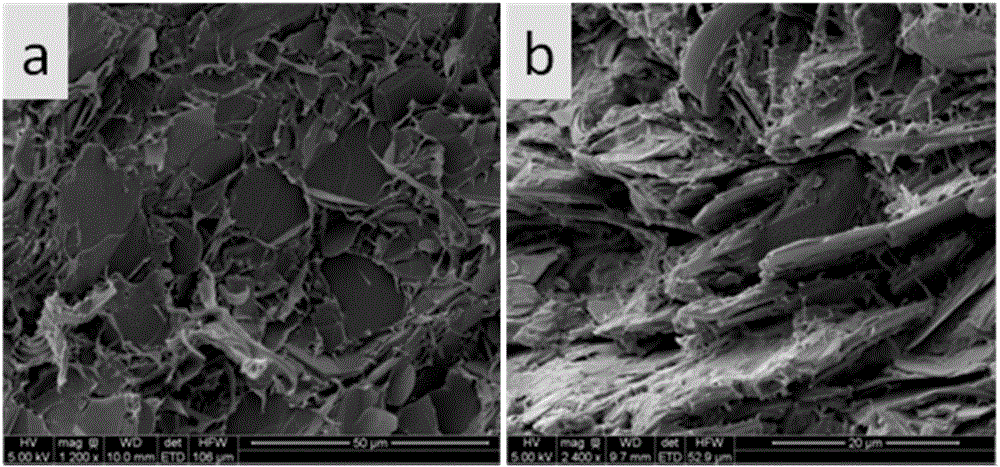

[0067] b) Vibrating the mixture obtained in step a) on a rotary vibrating table, so that the lamellar boron nitride powder realizes the preferential arrangement of the lamellar direction;

[0068] c) vacuum hot pressing the mixture subjected to step b) transverse vibration to obtain the composite material.

[0069] In another preferred example, the polymer is polyethylene, polypropylene, nylon, polyimide, polyphenylene sulfide.

[0070] In another preferred example, the mixing is carried out under the action of a double-center mixing and dispersing machine. The mixing speed is 1000-2000 rpm, and the mixing time is 30-120...

Embodiment 1

[0100] Example 1 Preparation of Boron Nitride Reinforced Polymer Matrix Composite Material 1

[0101] A: Measure the following components according to the following volume ratio:

[0102] Boron nitride powder 40vol%

[0103] Polyethylene powder 60vol%

[0104] B: After mixing the powder, put it into a double-center mixing and dispersing machine and stir for 30s, and the rotation speed is controlled at 1200rpm. The obtained mixture was put into a precision pressing mold, and after being uniformly vibrated on a rotary vibration table for 30 minutes, the rotational speed of the lateral vibration was 162 rpm.

[0105] C: After assembling the sample in step B with a mold, put it into a vacuum hot-press furnace, evacuate until the vacuum degree is below 200Pa, heat up to 150°C at a heating rate of 8°C / min, and perform hot pressing. The pressure is 20MPa, keep the pressure for 20min, then cool to room temperature with the furnace.

[0106] The high-temperature treated sample was ...

Embodiment 2

[0109] Example 2 Preparation of Boron Nitride Reinforced Polymer Matrix Composite Material 2

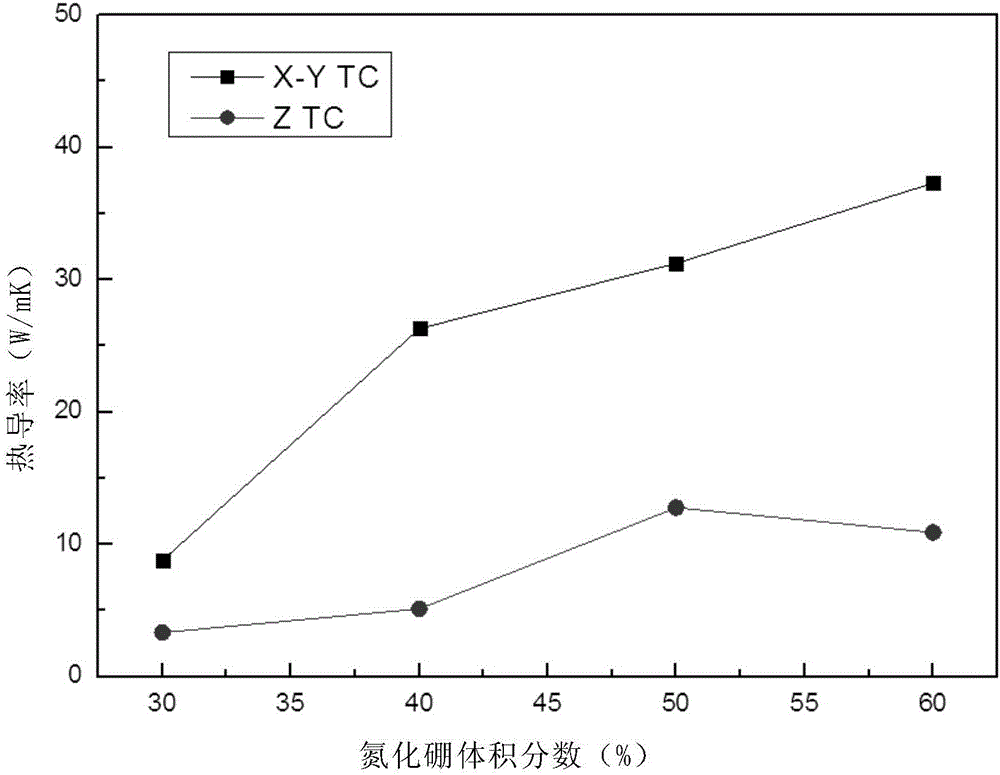

[0110] Same as Example 1, the difference is: the volume fraction of boron nitride powder is 30vol.%.

[0111] The measured thermal conductivity of the sample (whichever is the highest) is 8.78W / m.K, and the flexural strength is 32MPa.

[0112] The density is 1.345g / cm 3 , the thermal diffusivity in the vertical direction is 4.049mm 2 / s, the thermal diffusivity in the parallel direction is 1.707mm 2 / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com