Octa(chloro-propyl)-POSS/polyolefin spinning fiber gel polymer electrolyte and preparation method

A gel polymer, octachloropropyl technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, conjugated synthetic polymer artificial filaments, etc., can solve the difficult to meet the assembly requirements of dynamic LIB, spinning film mechanics Poor performance and other problems, to achieve high liquid absorption and porosity, improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Synthesis of POSS-(C 3 h 6 Cl) 8 , The ratio of raw materials is anhydrous methanol: chloropropyltrimethoxysilane: concentrated hydrochloric acid=100:5:4 (volume ratio). The POSS-(C 3 h 6 Cl) 8 and PVDF were placed in a vacuum oven at 60°C for 24 hours, and the polymer solvent DMF was distilled under reduced pressure and added Molecular sieves stand for more than 12h;

[0027] Step 2: Weigh DMF, acetone and PVDF according to the mass ratio of 68:17:15, heat and stir in a water bath at 30°C to form a polymer solution, and then weigh POSS-(C 3 h 6 Cl) 8 Blending with the above-mentioned polymer solution in turn, heating and stirring until it dissolves completely to obtain a spinning solution;

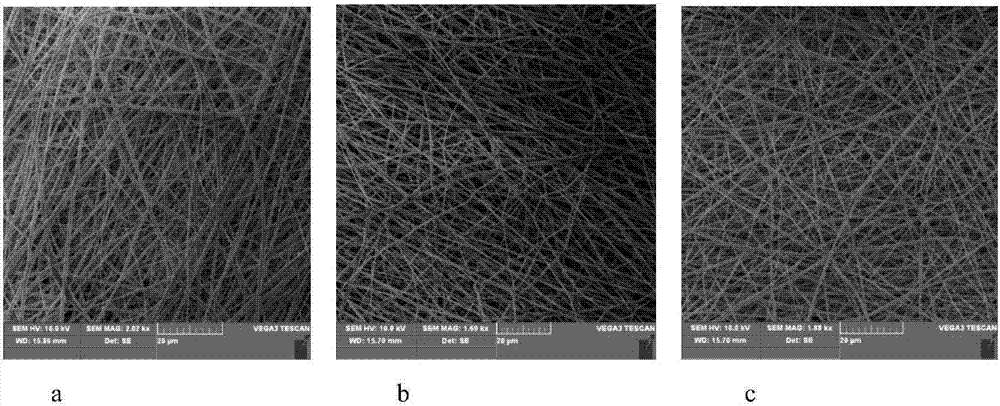

[0028] Step 3: Electrospin the spinning solution in step 2 on commercial PP to obtain a spun film, and dry it in a vacuum oven at 40° C. for 24 hours to obtain a POSS modified fiber film. The parameters of the electrospinning are: the spinning voltage is 15kV, th...

Embodiment 2

[0031] Step 1: Synthesis of POSS-(C 3 h 6 Cl) 8 , The ratio of raw materials is anhydrous methanol: chloropropyltrimethoxysilane: concentrated hydrochloric acid=100:5:4 (volume ratio). The POSS-(C 3 h 6 Cl) 8 and PVDF were placed in a vacuum oven at 60°C for 24 hours, and the polymer solvent DMF was distilled under reduced pressure and added Molecular sieves stand for more than 12h;

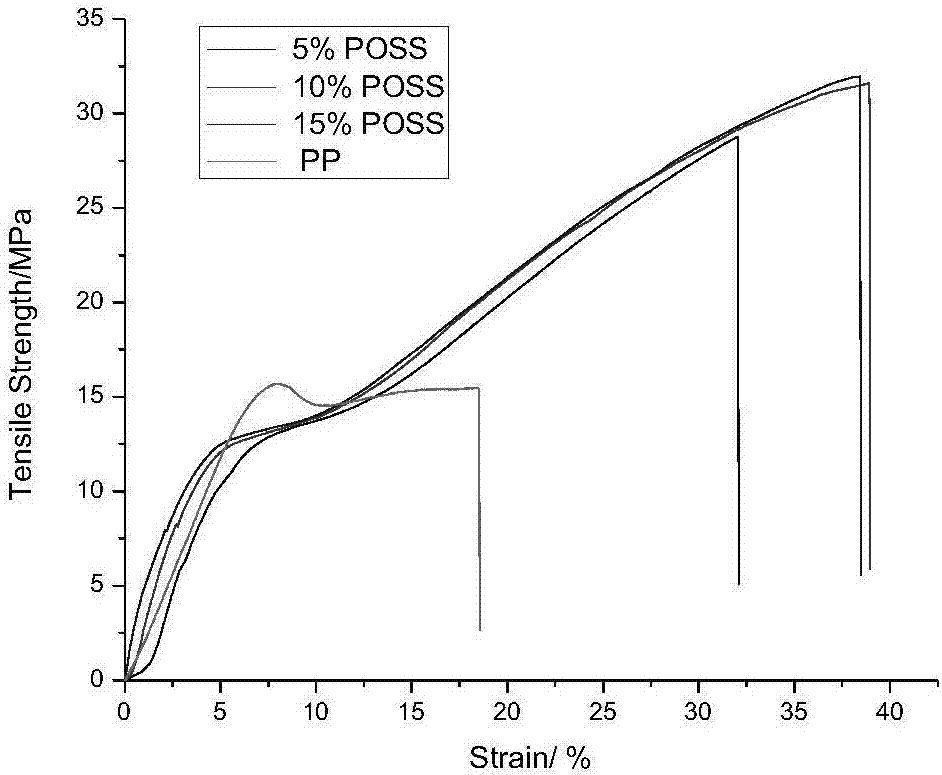

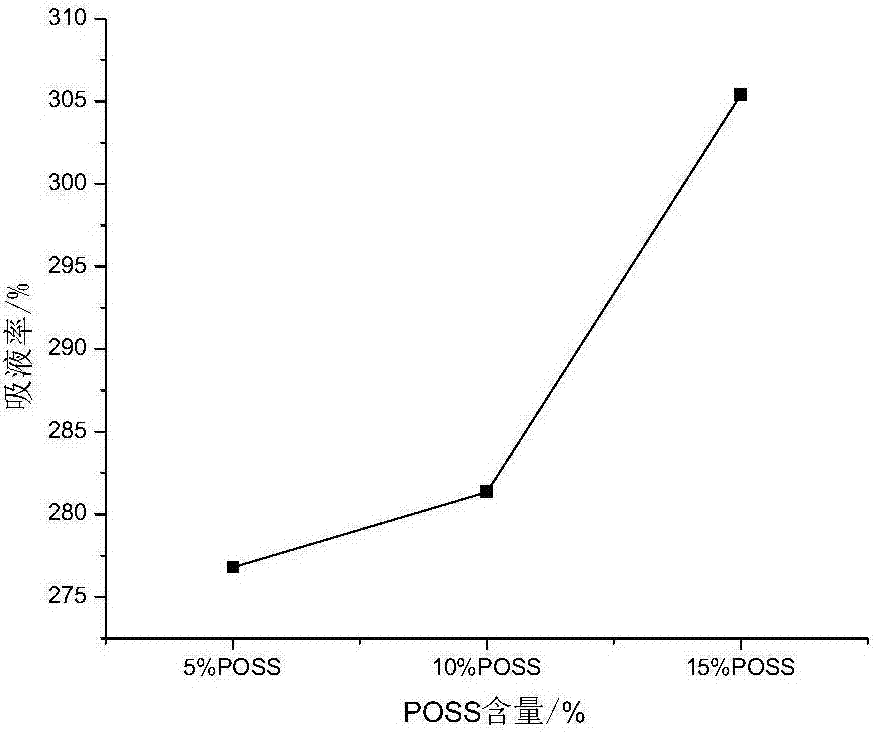

[0032] Step 2: Weigh DMF, acetone, PVDF, and PAN according to the mass ratio of 68:17:10:5, heat and stir in a water bath at 30°C to form a polymer solution, and then weigh 5%, 10%, and 15% of the mass sum of PVDF and PAN % Weigh POSS-(C 3 h 6 Cl) 8 Blending with the above-mentioned polymer solution in turn, heating and stirring until it dissolves completely to obtain a spinning solution;

[0033] Step 3: Electrospin the spinning solution in step 2 on commercial PP to obtain a spun film, and dry it in a vacuum oven at 40° C. for 24 hours to obtain a POSS modified fiber film. The param...

Embodiment 3

[0036] Step 1: Synthesis of POSS-(C 3 h 6 Cl) 8 , The ratio of raw materials is anhydrous methanol: chloropropyltrimethoxysilane: concentrated hydrochloric acid=100:5:4 (volume ratio). The POSS-(C 3 h 6 Cl) 8 and PVDF were placed in a vacuum oven at 60°C for 24 hours, and the polymer solvent DMF was distilled under reduced pressure and added Molecular sieves stand for more than 12h;

[0037] Step 2: Weigh DMF, acetone, PVDF, PMMA, and PAN according to the mass ratio of 68:16:8:4:4, heat and stir in a water bath at 30°C to form a polymer solution, and then weigh PVDF, PMMA, and PAN according to the mass sum of 5 %, 10%, 15% weigh POSS-(C 3 h 6 Cl) 8 Blending with the above-mentioned polymer solution in turn, heating and stirring until it dissolves completely to obtain a spinning solution;

[0038] Step 3: Electrospin the spinning solution in step 2 on commercial PP to obtain a spun film, and dry it in a vacuum oven at 40° C. for 24 hours to obtain a POSS modified fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com