End-capping reagent containing crosslinkable group, modified polyimide precursor resin, photosensitive resin composition and application thereof

A polyimide precursor and cross-linking group technology, applied in the field of photolithography, can solve the problems of poor heat resistance of cross-linking agents, limited improvement in thermal properties of materials, improved peel strength and mechanical properties, etc., to improve thermal stability. , the effect of reducing the amount of overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0078] Synthesis of hydroxyl-containing dianhydride monomer 1:

[0079]

[0080] Under a nitrogen atmosphere, dissolve 10.8g (0.05mol) of 3,3'-dihydroxy-4,4'-benzidine in 50mL of γ-butyrolactone, cool down to -15°C, and then dissolve 22.1g (0.105mol) ) 1,2,4-Trimellitic anhydride acid chloride was dissolved in 50mL γ-butyrolactone, and the latter was added dropwise to the previous solution (the reaction was exothermic, the reaction temperature should be kept below -5°C during the dropwise addition), after the dropwise addition Continue to react for 5h. Most of the solvent was removed by a rotary evaporator, and the concentrate was poured into 300 mL of toluene for precipitation to obtain the corresponding hydroxyl-containing dianhydride monomer 1.

[0081] Structural characterization: method: Fourier transform infrared spectroscopy (the instruments used for Fourier transform infrared spectroscopy characterization in the present invention are Spectrum One infrared spectrome...

Synthetic example 2

[0083] Synthesis of hydroxyl-containing dianhydride monomer 2:

[0084]

[0085]The difference from Preparation Example 1 is that 3,3'-dihydroxy-4,4'-benzidine is replaced by 5,5'-(1,4-phenylene bis(oxo)) Two (2-aminophenol), to obtain the hydroxyl-containing dianhydride monomer 2.

[0086] Structural characterization: method: Fourier transform infrared spectroscopy, characteristic peak: 1850cm -1 The characteristic peak of acid anhydride group is at 3400cm -1 The characteristic peak of -OH is at 1650cm -1 The place is the characteristic peak of amide group, 1240cm -1 is the characteristic peak of aromatic C-O-C.

Synthetic example 3

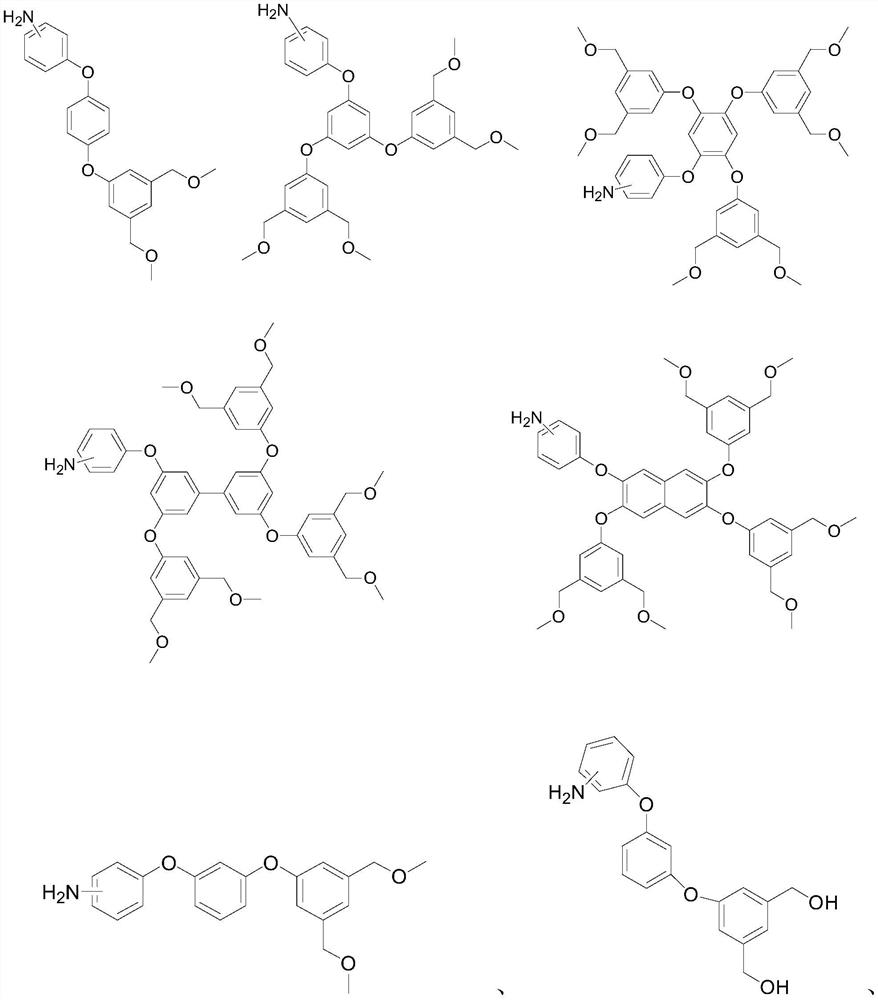

[0088] Synthesis of capping agent 1 containing crosslinkable groups:

[0089]

[0090] Take 1.39g (10mmol) m-nitrophenol, dissolve it in 20mL of DMSO solvent, then add 1.18g (5mmol) p-dibromobenzene and 3.69g (22mmol) CsOH·H 2 O, react in an oil bath at 150°C for 36 hours, follow the reaction by TLC, after the reaction is complete, the product is purified by column chromatography to obtain intermediate I;

[0091] Take 2.94g (10mmol) of intermediate I, dissolve it in 20mL of DMSO solvent, then add 1.54g (10mmol) of 3,5-dimethylolphenol and 3.69g (22mmol) of CsOH·H 2 O, 150 ° C oil bath reaction 36h, TLC tracking reaction, after the reaction is complete, the product was purified by column chromatography to obtain intermediate II.

[0092] Take 0.72g (30mmol) of sodium hydride, add it to 20mL of dry anisole solution, take another 3.67g (10mmol) of intermediate II, add 30mL of dry anisole solvent, add dropwise to the former solution, and reflux after the dropwise addition Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com