Sheath core fiber with night light far infrared function and preparation method thereof

A skin-core type, far-infrared technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of single fiber products that need to be developed, and achieve a wide range of uses, long-lasting functionality, and strong washability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Correspondingly, the present invention provides a method for preparing a sheath-core fiber with luminous far-infrared function, including the following steps:

[0034] Provide luminous masterbatch containing rare earth luminous materials and far-infrared masterbatch containing far-infrared ceramic materials respectively;

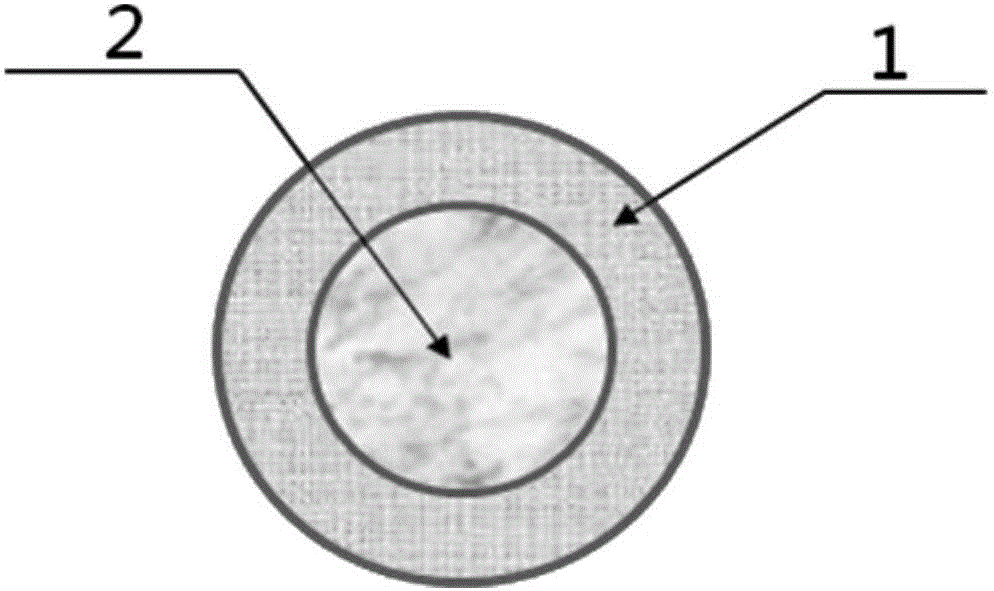

[0035] Melt spinning the luminous masterbatch and far-infrared masterbatch to obtain a core-sheath fiber with luminous far-infrared function. The skin layer of the core-sheath fiber is a polymer layer containing rare earth luminous materials, and the core layer is Polymer layer containing far-infrared ceramic material.

[0036] The preparation method provided by the present invention uses textile polymer raw materials as substrates to prepare functional fibers with luminous and far-infrared functions, namely luminous far-infrared functional fibers, which can improve the safety and warmth of the wearer and is suitable for outdoor activities at night Wear and...

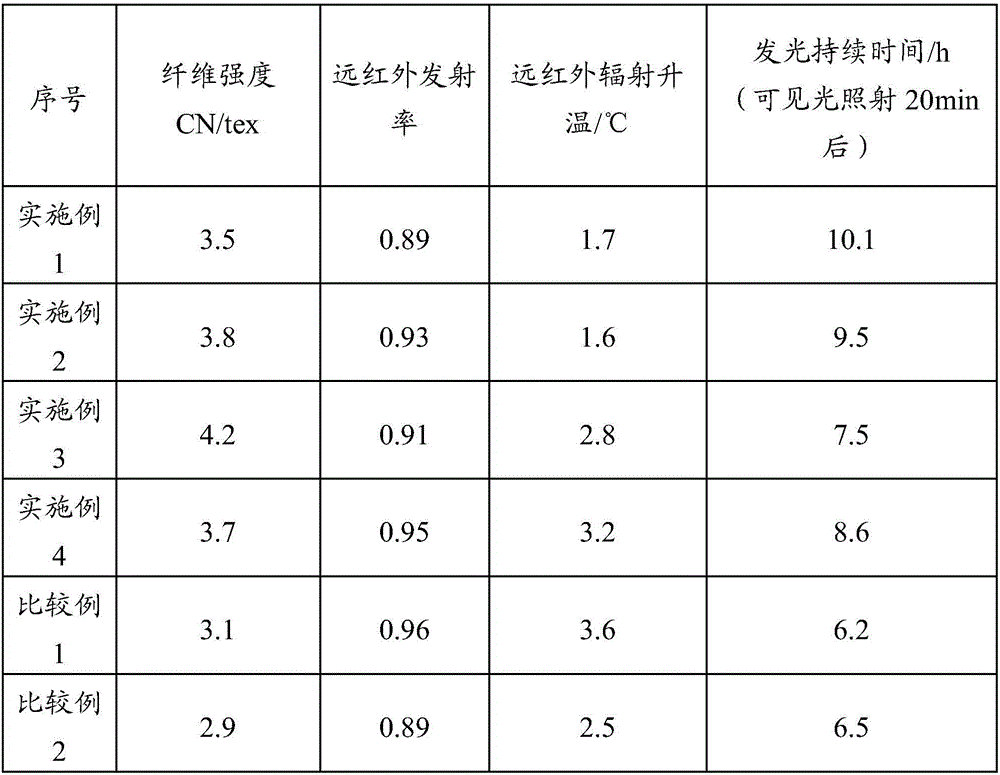

Embodiment 1

[0055] (1) Preparation of luminous masterbatch: 100 parts by weight of polyester chips are vacuum dried, and then 2 parts by weight of rare earth chlorate with a particle size of 50 nanometers, 1 part by weight of dispersant, 2 parts by weight of heat stabilizer, and light stabilizer are added 2 parts by weight and 3 parts by weight of antioxidant, fully stirred for 20 minutes, passed through a twin-screw melting granulator to obtain luminous masterbatch, which was dried by drum vacuum and ready for use; the temperature of melting granulation was set to 220°C, granulation was made The diameter is 0.7 cm.

[0056] (2) Preparation of far-infrared masterbatch: 100 parts by weight of polyester chips are vacuum dried, and then 3 parts by weight of alumina with a particle size of 500 nanometers and 3 parts by weight of polymer spinning aid are added, mixed uniformly, and manufactured by twin-screw melting The granulator obtains the far-infrared masterbatch, which is vacuum-dried by a r...

Embodiment 2

[0060] (1) Preparation of luminous masterbatch: 100 parts by weight of polypropylene slices are vacuum dried, and then 5 parts by weight of rare earth aluminate with a particle size of 100 nm, 2 parts by weight of dispersant, 2 parts by weight of heat stabilizer, and light stabilizer are added 2 parts by weight and 2 parts by weight of antioxidant, fully stirred for 40 minutes, passed through a twin-screw melting granulator to obtain luminous masterbatch, which was dried by rotating drum and vacuum, and ready for use; the melting granulation temperature was set to 180°C, and the granulation The diameter is 1.1 cm.

[0061] (2) Preparation of far-infrared masterbatch: 100 parts by weight of polypropylene chips are vacuum dried, then 4 parts by weight of titanium dioxide with a particle size of 0.3 microns and 3 parts by weight of polymer spinning aid are added, mixed evenly, and then melted and granulated by twin screw Machine to obtain the far-infrared masterbatch, which is vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com