Textile material production method and application of product serving as medical packaging material

A production method and packaging material technology, applied in textiles and papermaking, pharmaceutical formulations, and liquid repellent fibers, etc., can solve the problems of lowering, less recognized by domestic hospitals, and seldom used, and achieve cost reduction, good quality The effect of washing resistance and improving reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

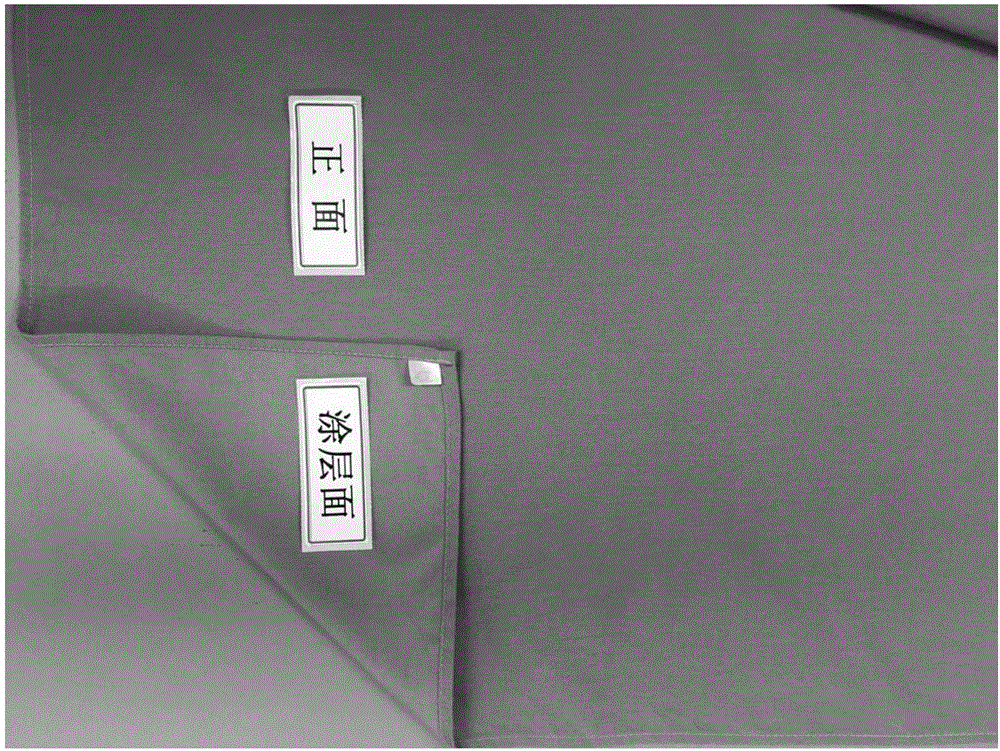

[0042] process such as figure 1 Shown:

[0043] (1) Spinning and weaving to obtain gray cloth (containing 65% polyester and 35% cotton), TC 21s×21s, 108×58 (“TC” means polyester cotton; “21s×21s” means yarn count: warp direction 21s , 21s in weft direction; "108×58" means density: 108 pcs / inch in warp direction, 58 pcs / inch in weft direction);

[0044] (2) dyeing gray cloth to obtain dyed cloth;

[0045] (3) the dyed cloth is carried out waterproof cross-linking treatment with the mixed solution of the following formula;

[0046] Waterproofing agent C6 (AG-E061): 100g / L, crosslinking agent (end-blocked sodium isocyanate, MEIKANTE FM-1): 30g / L, solvent is water, acetic acid to adjust the pH value to 5-6;

[0047] Adopt padding method, speed: 30m / min;

[0048] (4) calendering;

[0049] (5) Coating:

[0050] Equipment: Floating knife scraping coating

[0051] Vehicle speed: 20~25m / min;

[0052] Curing temperature: 150°C;

[0053] Solution formulation for coating:

[005...

Embodiment 2

[0058] In step (5), dilute the mixed solution A (1 part mixed solution A + 1 part water, that is: dilute the concentration of the polyurethane coating in the mixed solution A from "100g / L" to "50g / L") as a coating solution, other process steps and process conditions are the same as in Example 1 to obtain finished product C-II.

Embodiment 3

[0060] In step (5), dilute the mixed solution A (1 part mixed solution A + 3 parts water, that is: dilute the concentration of the polyurethane coating in the mixed solution A from "100g / L" to "25g / L") as a coating solution, other process steps and process conditions are the same as in Example 1 to obtain finished product C-Ⅲ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com