Friction nanometer power generation system driven by thermo-acoustic engine

A thermoacoustic engine and nano-power generation technology, which is applied in the direction of friction generators, machines/engines, mechanisms for generating mechanical power, etc., can solve the problem of limiting the application range of friction nano-generators, weakening the advantages of high reliability, and failing to provide continuous and stable To solve the problems of electric energy and other issues, to achieve the effect of various preparation materials, high potential thermoelectric efficiency, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

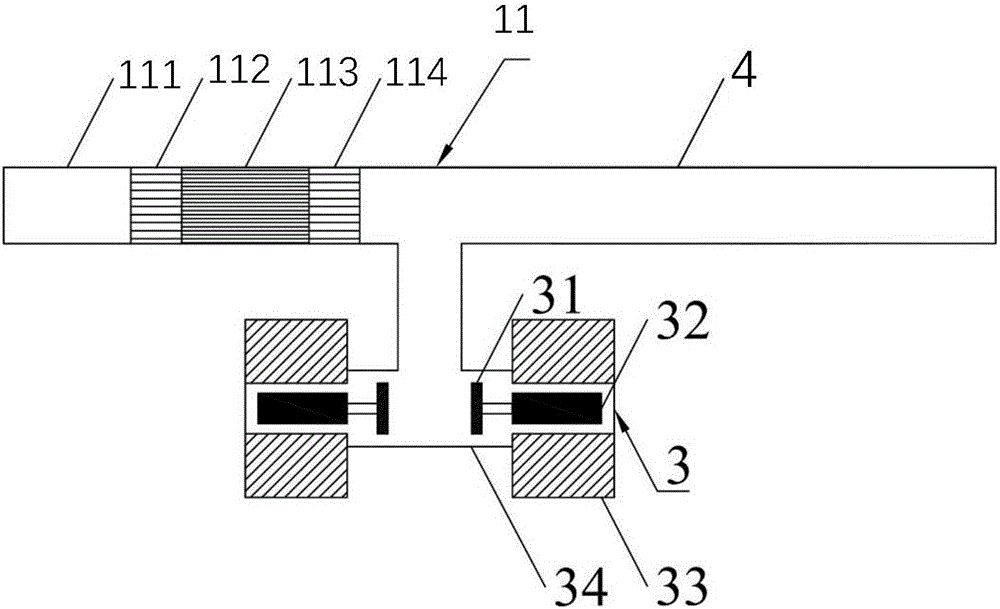

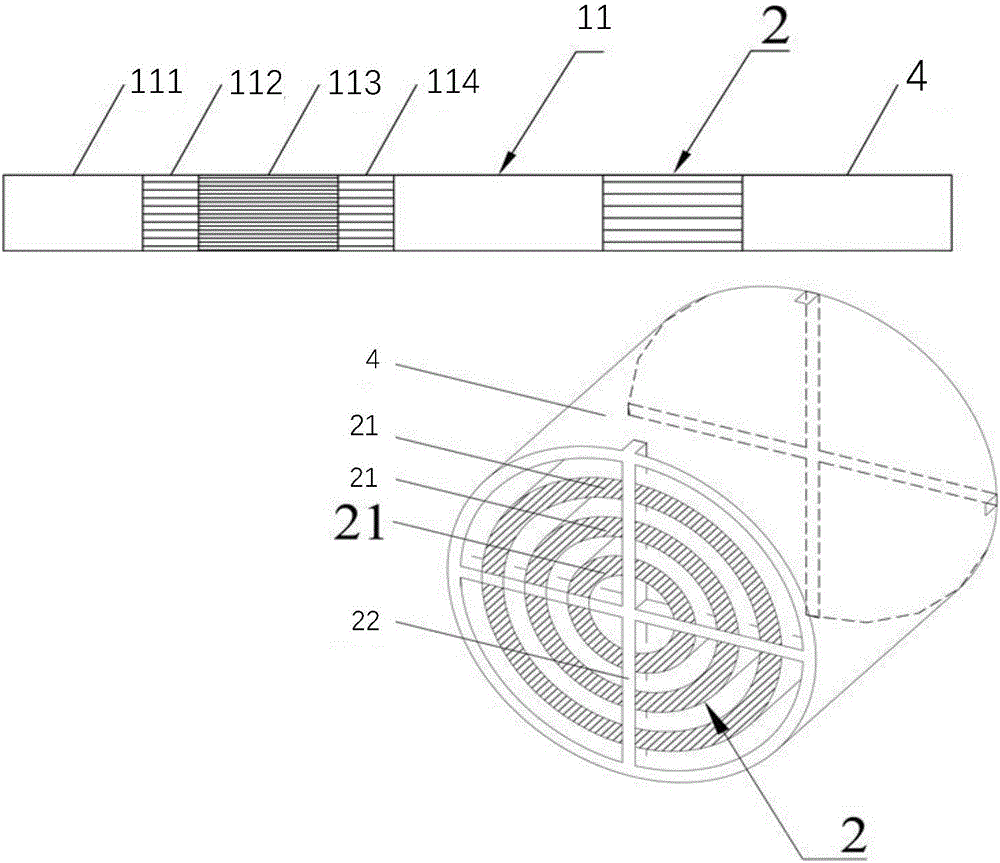

[0054] figure 2 It is a structural schematic diagram of a frictional nano power generation system driven by a thermoacoustic engine in Embodiment 1 of the present invention, which includes: a standing wave thermoacoustic engine 11 and a resonant tube 4 installed in the standing wave thermoacoustic engine Triboelectric nanogenerator set 2.

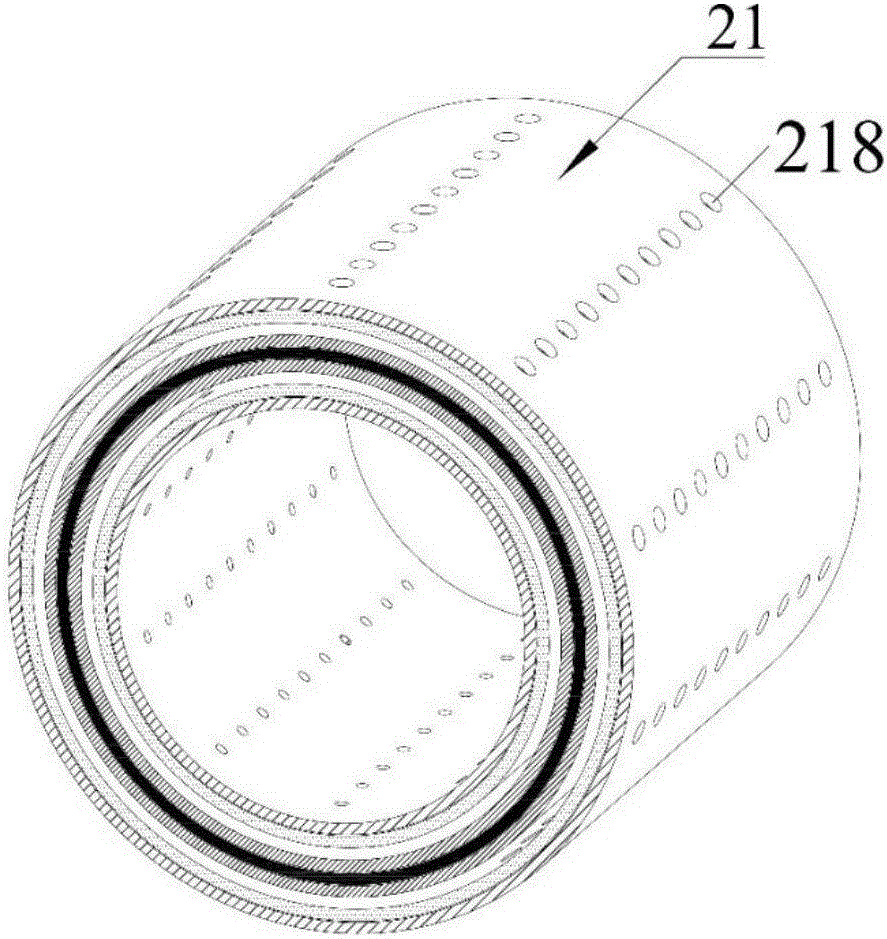

[0055] The standing wave thermoacoustic engine 11 includes a thermal cavity 111 , a heater 112 , a plate stack 113 , and a room temperature heat exchanger 114 connected in sequence, and the room temperature heat exchanger 114 communicates with the resonance tube 4 . The friction nanogenerator unit 2 is a thin-walled cylindrical structure, located in the resonance tube 4, including three cylindrical friction nanogenerator units 21 with the same structure and generator brackets located at both ends of the friction nanogenerator unit 2 22 ; the three triboelectric nanogenerator units 21 are coaxial and distributed at equal intervals along th...

Embodiment 2

[0065] Figure 6 It is a structural schematic diagram of a frictional nano-power generation system driven by a thermoacoustic engine in Embodiment 2 of the present invention, which includes: a traveling wave thermoacoustic engine and a friction tube installed in a resonance tube 4 connected to the traveling wave thermoacoustic engine Nano Generator Set 2. The traveling wave thermoacoustic engine is a loop traveling wave thermoacoustic engine 121 with a standing wave resonance tube, which includes a traveling wave loop, and the traveling wave loop communicates with the resonance tube 4 . The traveling wave loop includes a thermoacoustic engine unit consisting of a main room temperature heat exchanger 1211 , a regenerator 1212 , a loop heater 1213 , a thermal buffer tube 1214 and a secondary room temperature heat exchange tube 1216 . The device 1215 is formed in a ring shape. The frictional nanogenerator set 2 is a thin-walled cylindrical structure and is located in the resona...

Embodiment 3

[0070] Figure 7 It is a structural schematic diagram of a frictional nanometer power generation system driven by a thermoacoustic engine in Embodiment 3 of the present invention, which includes: a 3-stage acoustic resonance traveling wave thermoacoustic engine, 3 frictional nanometer power generation units, the 3 The first-level acoustic resonance traveling wave thermoacoustic engine is connected end to end by a thermoacoustic engine unit and a resonance tube to form a loop structure. The thermoacoustic engine unit is composed of a main room temperature heat exchanger 1211 , a regenerator 1212 , an annular heater 1213 , a thermal buffer pipe 1214 and a secondary room temperature heat exchanger 1215 connected in series. The friction nanogenerator set 2 is a thin-walled cylindrical structure, and is located in the resonant tube 4 of the acoustic resonance type traveling wave thermoacoustic engine. The structure and working principle of the frictional nanogenerator set 2 are ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com