Conformal graphene-based capacitive pressure sensor and preparation method thereof

A pressure sensor, graphene electrode technology, applied in the field of electronics, can solve problems such as low sensitivity and small pressure test range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

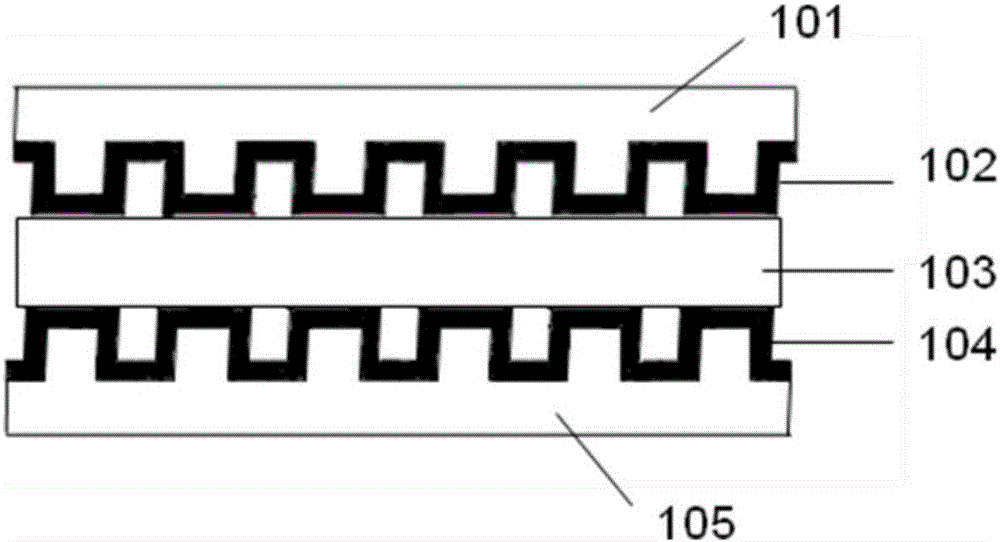

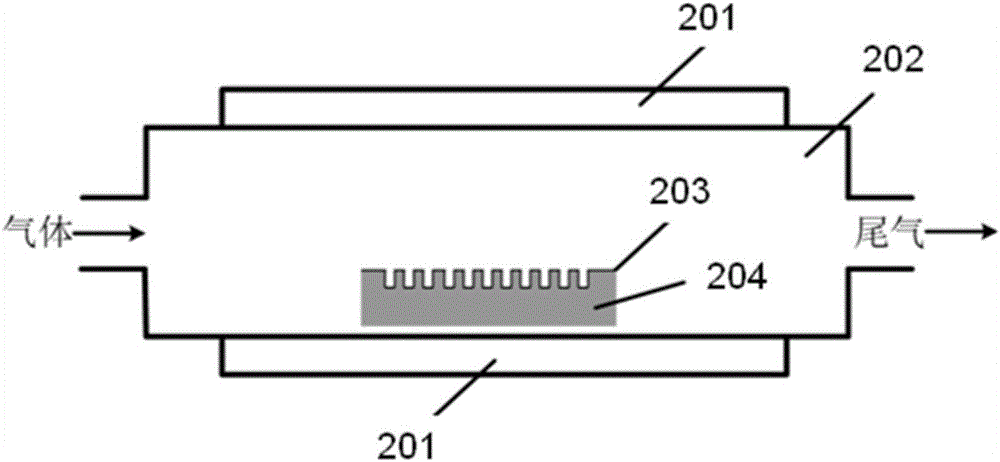

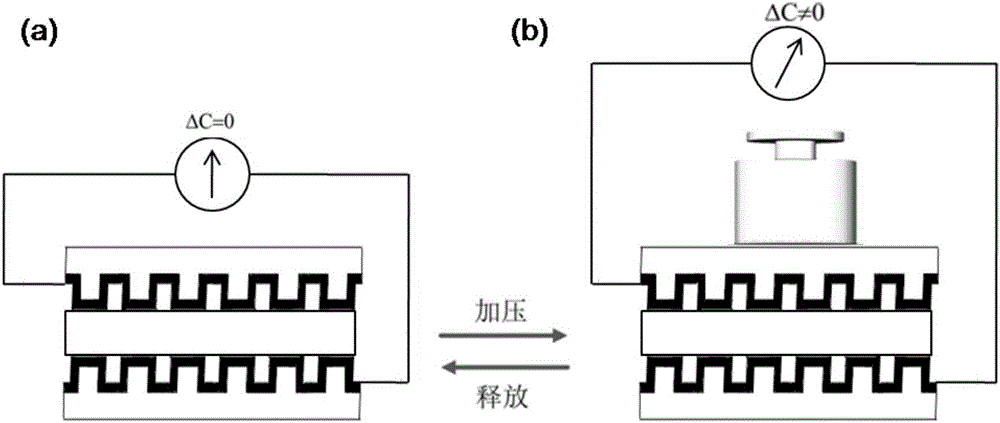

[0033] This embodiment provides a capacitive pressure sensor based on conformal graphene, the sensor is a flat structure, specifically as attached figure 1 As shown, there are three main layers from top to bottom: graphene electrode layer, dielectric layer and graphene electrode layer; the upper and lower graphene electrode layers are both grating-shaped conformal graphene transparent conductive films, as shown in the attached Figure 4 As shown in (a), the upper grating-shaped conformal graphene transparent conductive film is assembled from conformal graphene 102 and polymer elastomer 101, and the lower grating-shaped conformal graphene transparent conductive film is composed of conformal graphene 104 and The polymer elastomer 105 is assembled; the material of the polymer elastomer 101 and 105 is flexible TPU; the conformal graphene 102 and 104 are single-layer graphene, the square resistance is ~900Ω / sq, and the light transmittance range is ~95 %; The material of the dielect...

Embodiment 2

[0045] This embodiment provides a capacitive pressure sensor based on conformal graphene, the sensor is a flat structure, specifically as attached Figure 5 As shown, there are three main layers from top to bottom: graphene electrode layer, dielectric layer and graphene electrode layer; the upper graphene electrode layer is a cone-shaped conformal graphene transparent conductive film, as shown in the attached Figure 4 As shown in (f), the cone-shaped conformal graphene transparent conductive film is directly assembled by polymer elastomer 301 supporting conformal graphene 302. The material of polymer elastomer 301 is flexible PDMS, conformal graphite Graphene 302 is three layers of graphene, square resistance ~ 100Ω / sq, light transmittance range is ~ 85%; the lower graphene electrode layer is made up of planar polymer elastomer 305 and planar graphene film 304, polymer elastomer 305 is PET, the planar graphene film 304 is single-layer graphene, the square resistance is ~200Ω / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com