Grinding device for ceramic tile production

A grinding device and ceramic tile technology, applied in clay preparation devices, grain processing, chemical instruments and methods, etc., can solve the problems of low production efficiency of ceramic tiles and high labor intensity of workers, and achieve high quality and efficiency, saving waste. time, the effect of promoting fast grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

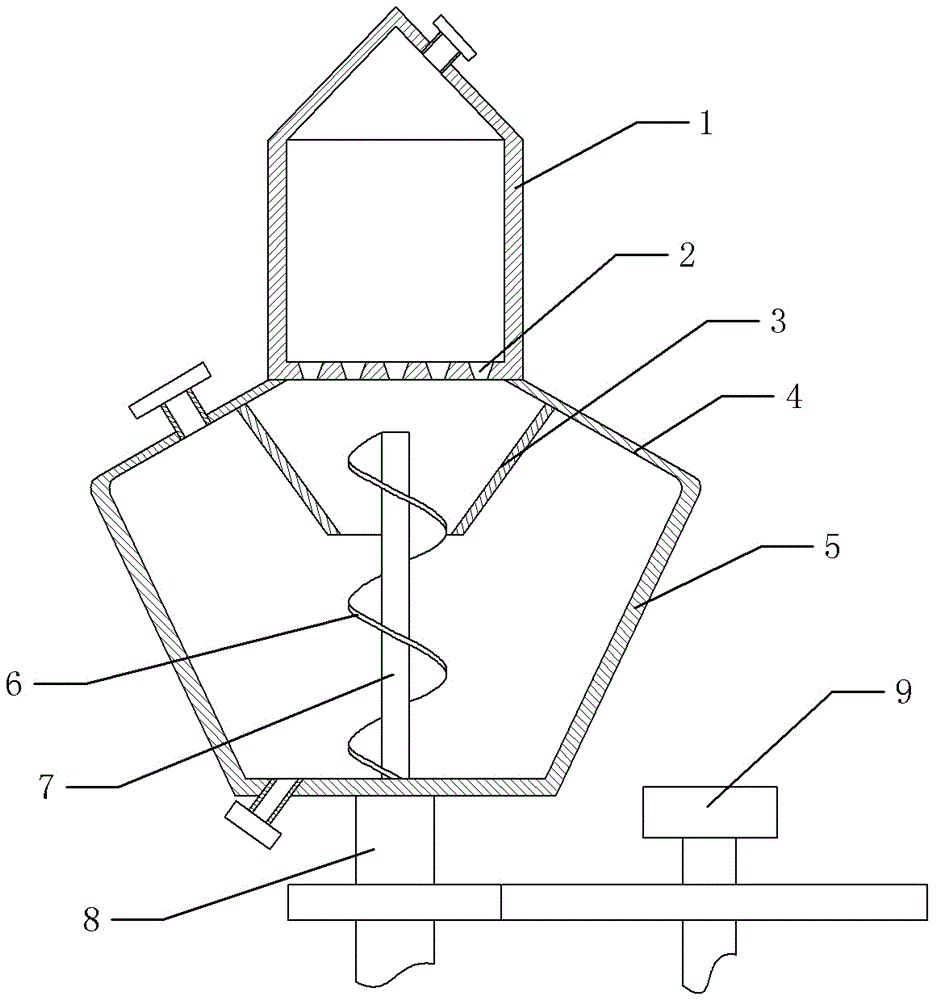

[0020] The reference signs in the accompanying drawings of the description include: hard material grinding bucket 1, screen hole 2, retaining cylinder 3, return flow part 4, centrifugal part 5, baffle plate 6, fixed shaft 7, rotating shaft 8, and motor 9.

[0021] Such as figure 1 As shown, the grinding device for ceramic tile production includes a hard material grinding barrel 1 and a clay grinding barrel located below the hard material grinding barrel 1, both of which together form a closed grinding cavity. The lower end of the clay grinding barrel is provided with a rotating shaft 8, and the rotating shaft 8 is connected with a motor 9 through a gear mechanism.

[0022] The upper end of the hard object grinding barrel 1 is conical, and the upper end is provided with a hard object feeding port, and the hard object feeding port is provided with a first cover; The sieve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com