Load structure integrated sensor flight vehicle

A sensor and aircraft technology, applied in the field of unmanned aerial vehicles, can solve the problems of insufficient performance and observation blind spots, etc., and achieve the effect of improving flight time and mission flight capability, lightweight design, and performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

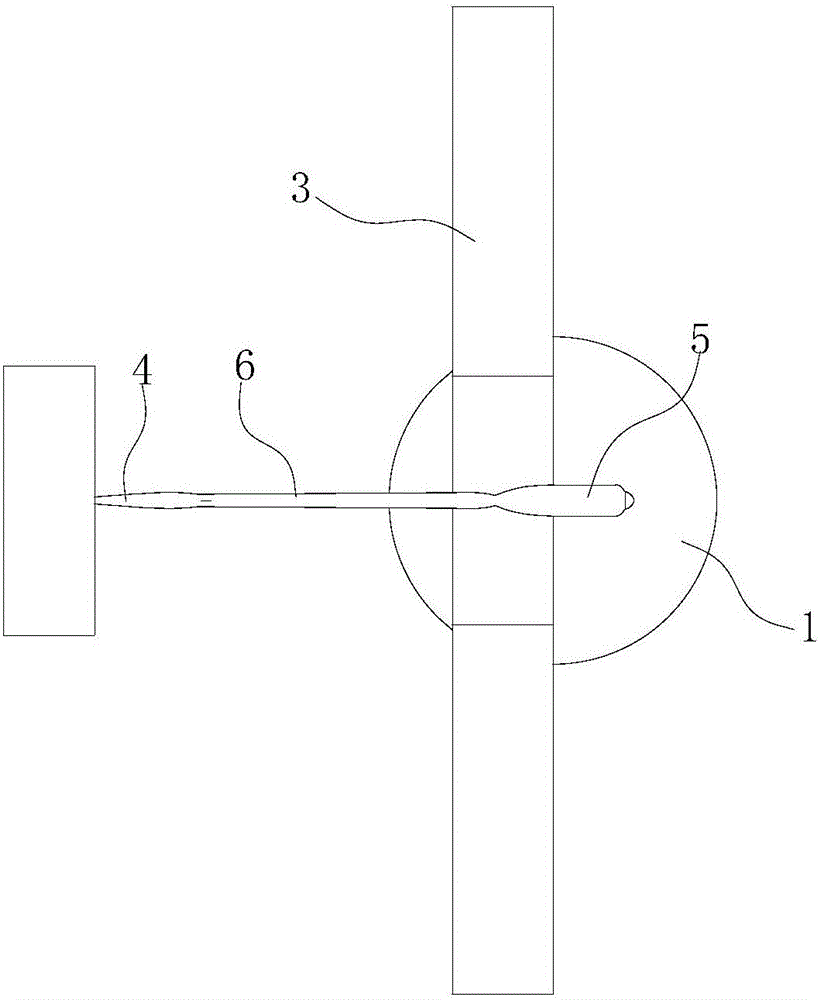

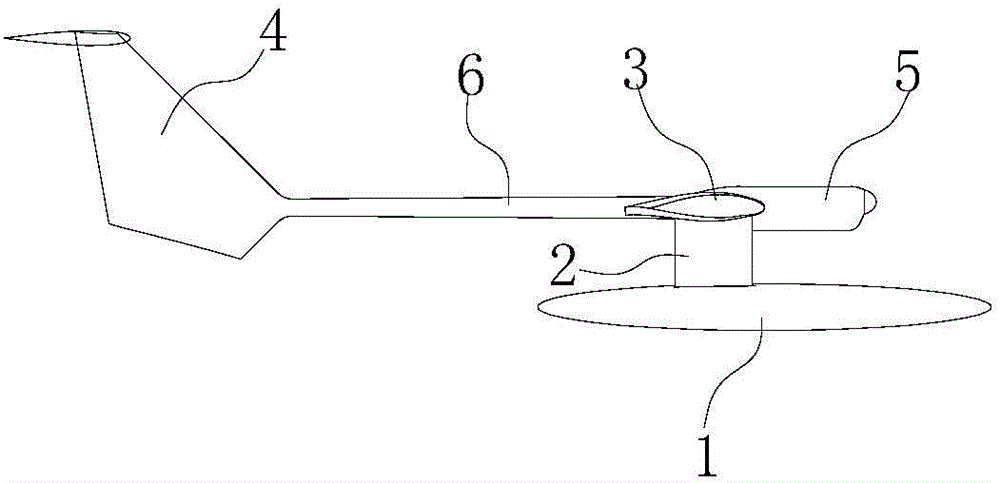

[0026] Such as Figure 1~4 As shown, the present embodiment adopts a circular fuselage 1a, a straight wing 3a, a single engine 5a, a single vertical empennage 4a and a horizontal empennage 4b, and the fuselage 1a hangs below the aerodynamic structure through a bracket 2.

Embodiment 2

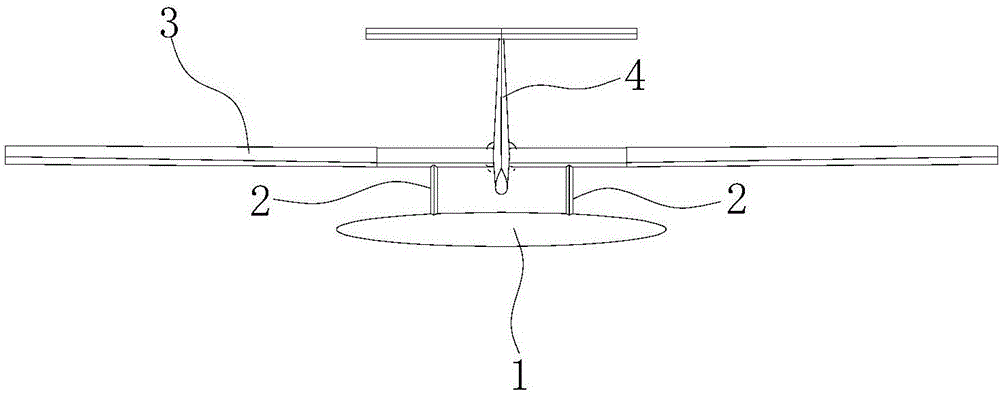

[0028] Such as Figure 5 As shown, the present embodiment adopts circular fuselage 1a, straight wing 3a, twin engines 5b, double vertical tail 4c and horizontal tail 4b, and fuselage 1a hangs below the aerodynamic structure through bracket 2.

Embodiment 3

[0030] Such as Figure 6 As shown, this embodiment adopts a shield-shaped fuselage 1b, a swept wing 3b with a tip-to-tip ratio, a single engine 5a, a single vertical tail 4a and a horizontal tail 4b, and the fuselage 1b hangs below the aerodynamic structure through a bracket 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com